Monitoring system and method of remote temperature image of substation

A temperature image and monitoring system technology, applied in the field of substation remote image monitoring technology, can solve personal safety and health threats, reduce work efficiency, resource waste and other problems, to avoid the impact of data transmission, avoid electromagnetic impact, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

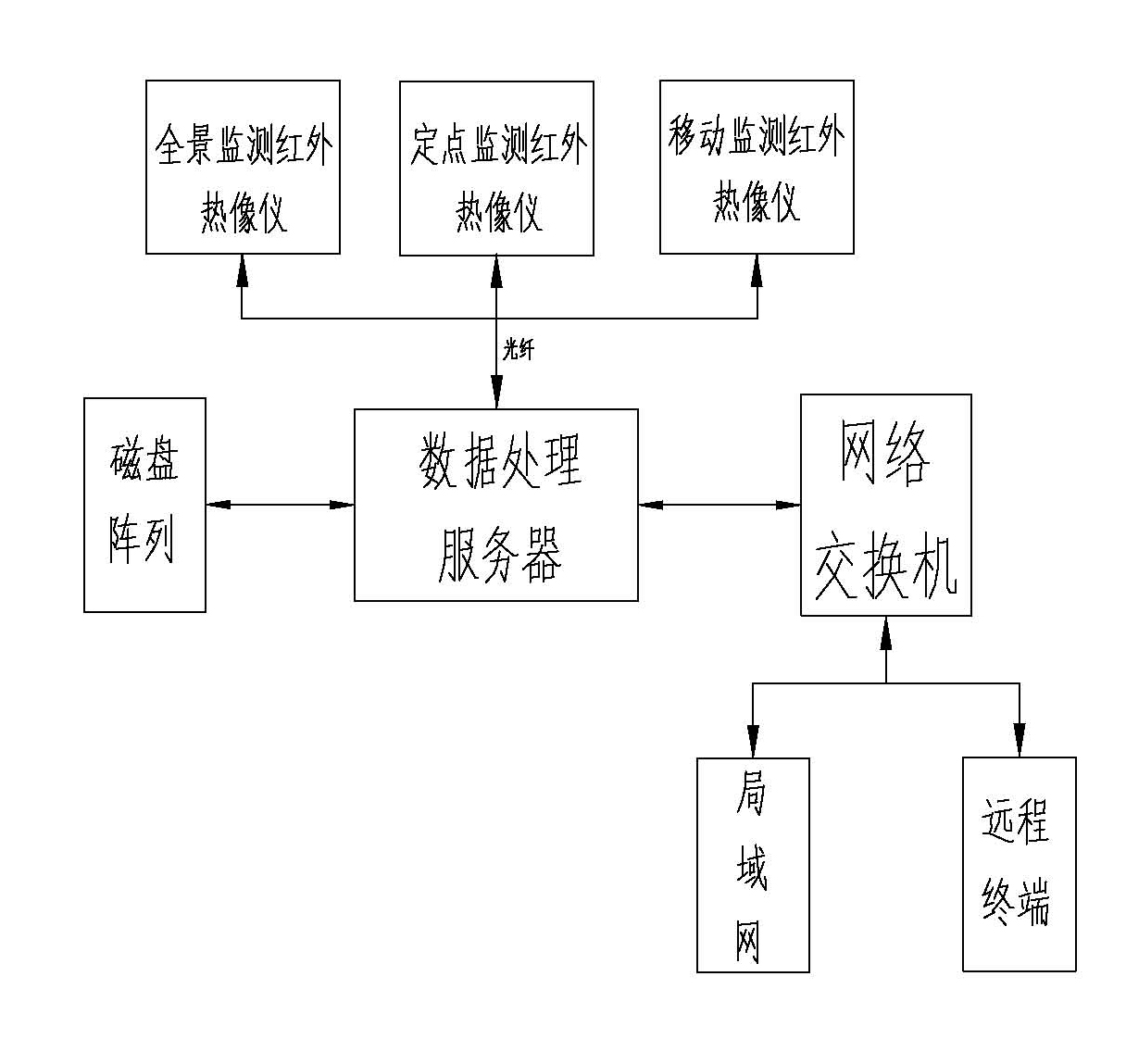

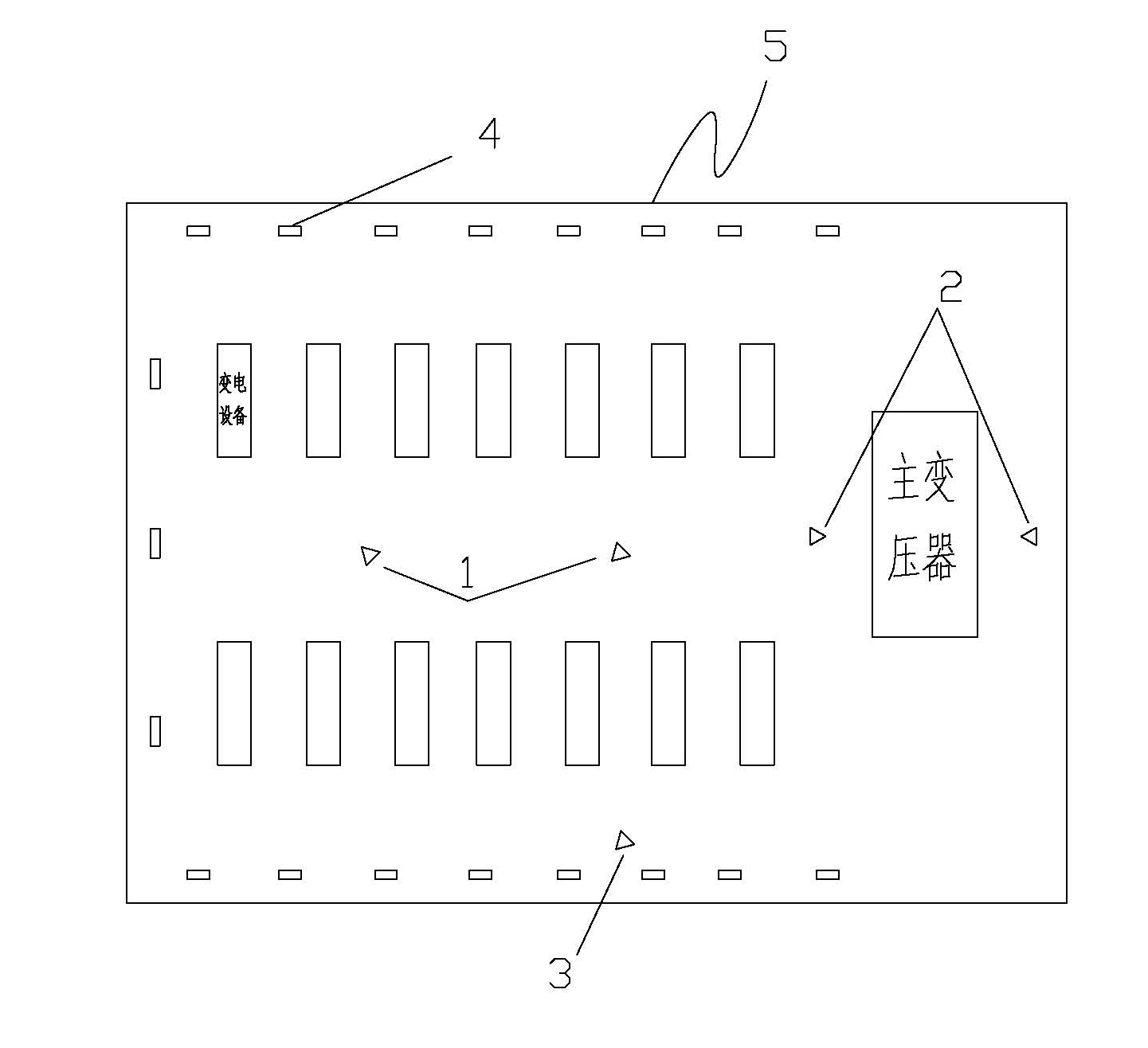

[0028] Such as figure 1 and figure 2 As shown, there are two high-resolution panoramic monitoring infrared thermal imaging cameras 1 at the central position in the substation 5. The panoramic monitoring infrared thermal imaging cameras are used to monitor all general equipment in the substation except the main transformer. The panoramic monitoring infrared thermal imaging cameras The camera is equipped with a pan-tilt that can rotate freely within a 360-degree viewing angle; the panoramic monitoring infrared thermal imager has a long detection distance and a short monitoring time, so it is impossible to judge the cause and level of the fault. In order to overcome this defect, when the panoramic monitoring infrared thermal imager When the thermal imager detects a fault, use a medium-resolution mobile monitoring infrared thermal imager 3 to monitor the fault location for a cycle; two low-resolution fixed-point monitoring infrared thermal imaging cameras are installed on the fro...

Embodiment 2

[0031] refer to figure 2 As shown, on the basis of embodiment 1, the method for remote temperature image monitoring of the substation comprises the following steps: a, two high-resolution panorama monitoring infrared thermal imaging cameras 1 are arranged in the substation 5 to conduct panorama of the substation Monitoring, so that the monitoring range of each panoramic monitoring thermal imaging camera is the largest and the monitoring range overlap is the smallest, wherein any device in the substation is covered by the monitoring range of at least one panoramic monitoring thermal imaging camera; b. High-rate fixed-point monitoring thermal imager 2 is set on the front and rear sides of the main transformer to monitor the main transformer; c. When an abnormal device is found in step a, use a mobile monitoring thermal imager 3 with a medium resolution to check the abnormal device periodic monitoring.

[0032] The information collected in the above three steps is transmitted t...

Embodiment 3

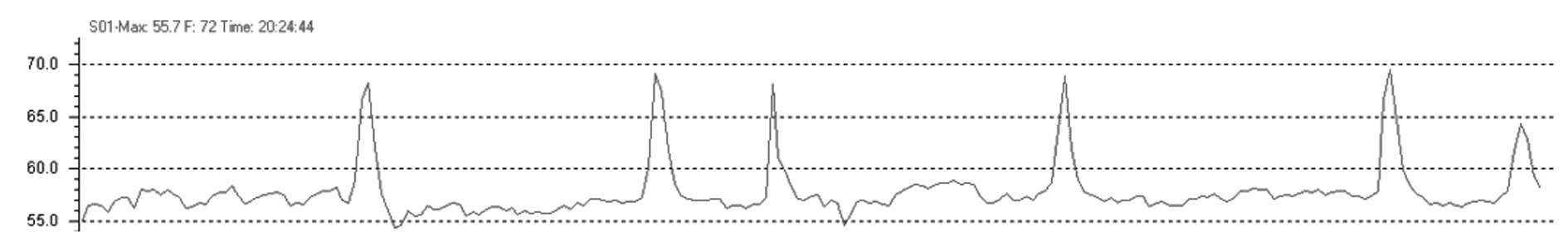

[0039] see image 3 . image 3 It is the temperature analysis curve of this system for the fault detection of the low-voltage side of the 220Kv main transformer. The detection time is at midnight, where C03 is the temperature curve of B phase, and C01 is the temperature curve of A phase. From the temperature analysis curve, it is known that when the equipment is at midnight, the power consumption decreases, and the temperature of phase B (C03) decreases, but the temperature of phase A (C01) does not decrease with the decrease of load, which shows that phase A is not a simple Poor contact, but a thermal defect caused by voltage and current loads. The above defects cannot be determined by general hand-held testing equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com