Low-temperature high-efficiency fluidization combined drying process and equipment thereof

A combined drying and fluidization technology, which is applied in the direction of drying machine combination, drying solid materials, lighting and heating equipment, etc., can solve the problems of harsh drying environmental conditions, unstable quality control, uneven water content, etc., and achieve effective Conducive to deep processing, prevent overheating, high-quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

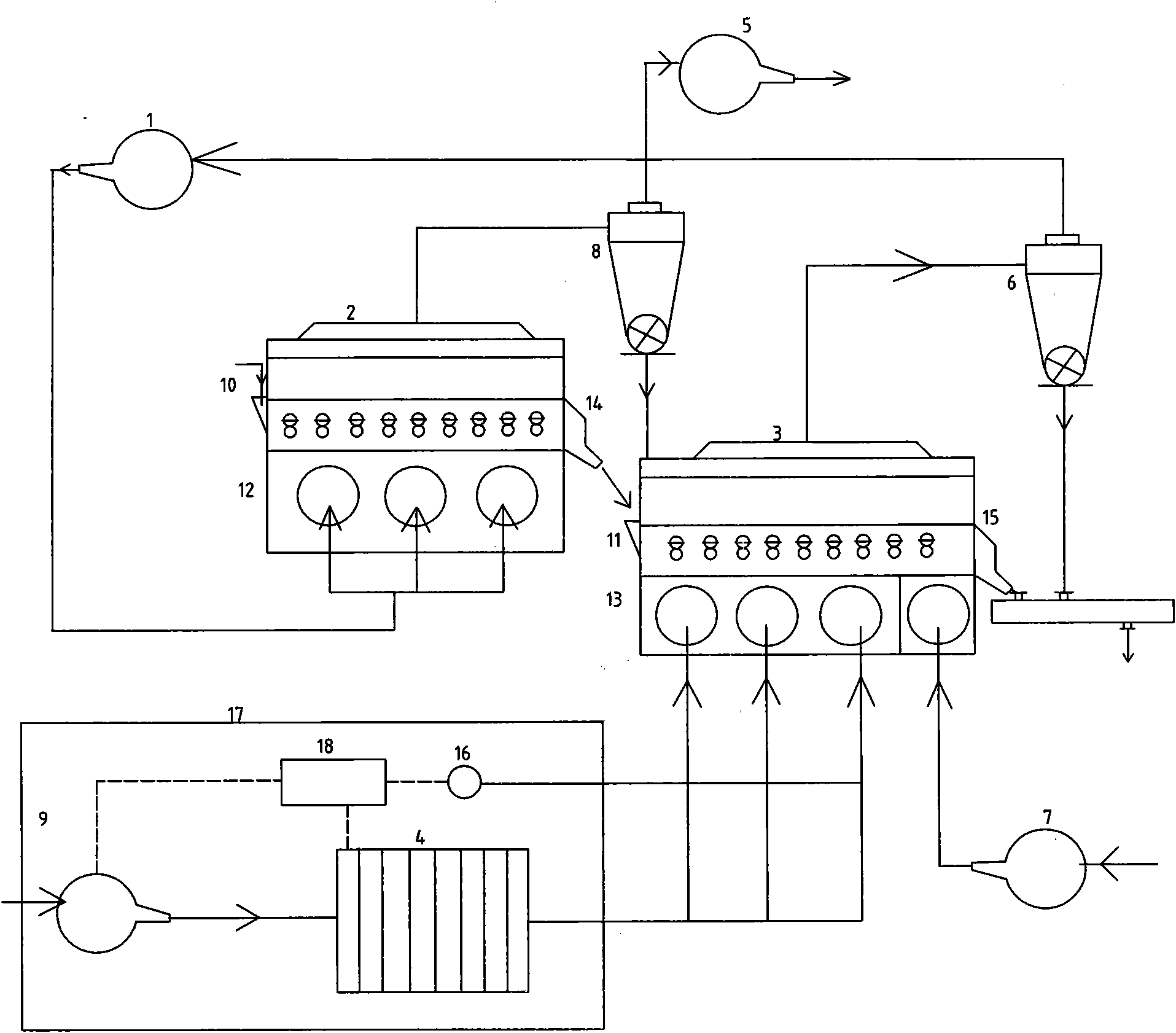

[0033] Such as figure 1 As shown, the low-temperature and high-efficiency fluidized combined drying equipment of the present invention includes a fluidized bed drying device 2, a fluidized bed drying device 3, a cyclone separator, a blower and a temperature control device; the fluidized bed drying device 2 includes a feed inlet 10, discharge port 14, exhaust port (not shown in the figure, be arranged on the top of device) and drying chamber 12; Described fluidized bed drying device 3 comprises feed inlet 11, discharge port 15, exhaust port (not shown in the figure, be arranged on the top of device) and drying chamber 13; The discharge opening 14 of described fluidized bed drying device 2 and the feed inlet 11 of fluidized bed drying device 3 are connected to form a continuous two-stage flow Combined fluidized bed drying device; the exhaust port of the fluidized bed drying device 2 is sequentially connected with the cyclone separator A8, the fluidized bed drying device 3, the c...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the waste heat utilization primary pre-drying device 2 is a fluidized bed dryer, and the secondary drying device 3 is an airflow dryer. The figure is omitted, and raw grain is used as the material.

Embodiment 3

[0047] The difference between this embodiment and Embodiment 1 is that the waste heat utilization primary pre-drying device 2 is a fluidized bed dryer, and the secondary drying device 3 is a rotary cylinder dryer. The figure is omitted, and feed yeast is used as the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com