Cradle stress and deformation early warning system

An early warning system and stress technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of relying on personnel, difficult measurement, unfavorable discovery and processing, etc., to prevent malignant accidents, ensure construction safety, and ensure construction quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

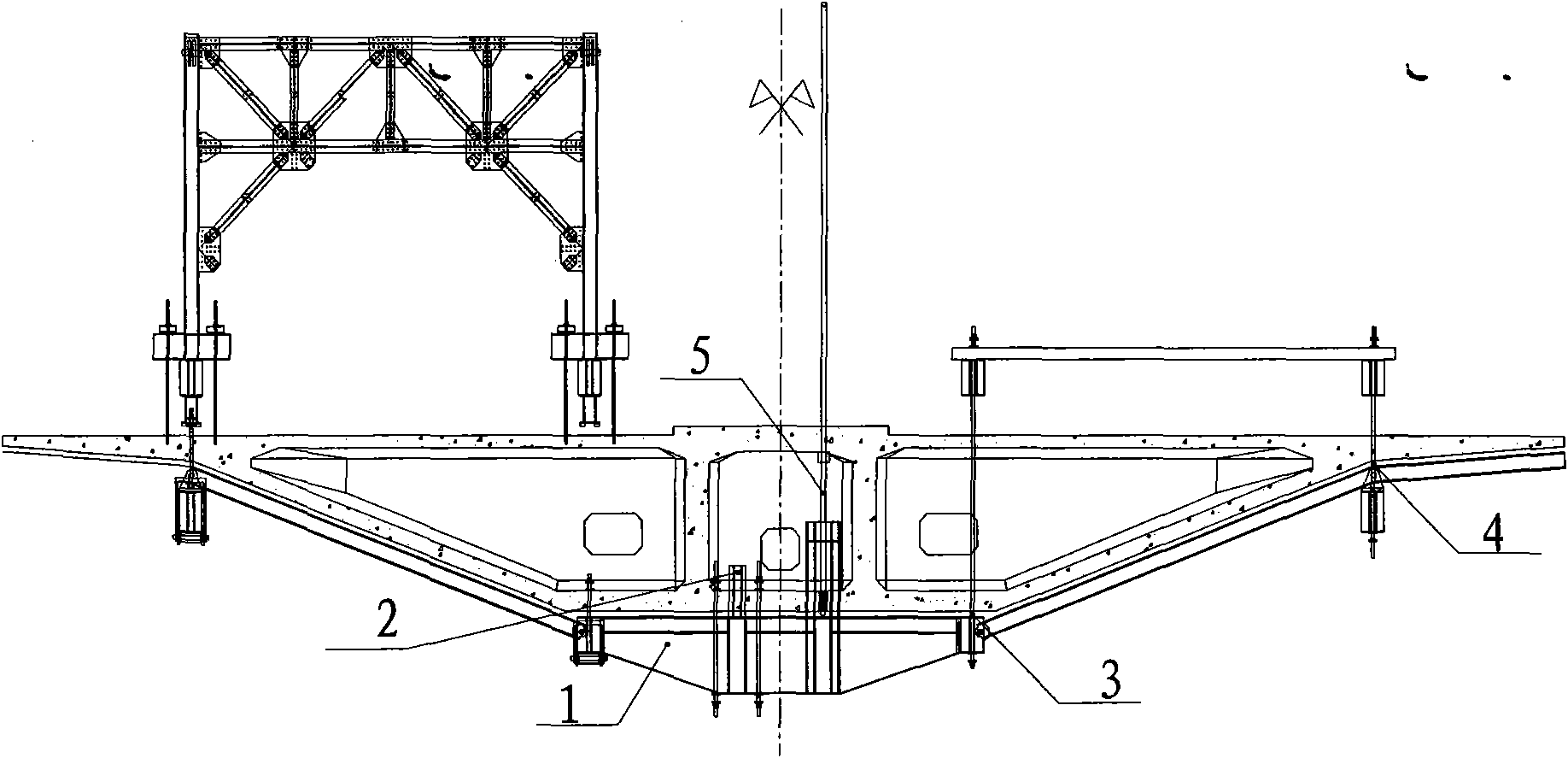

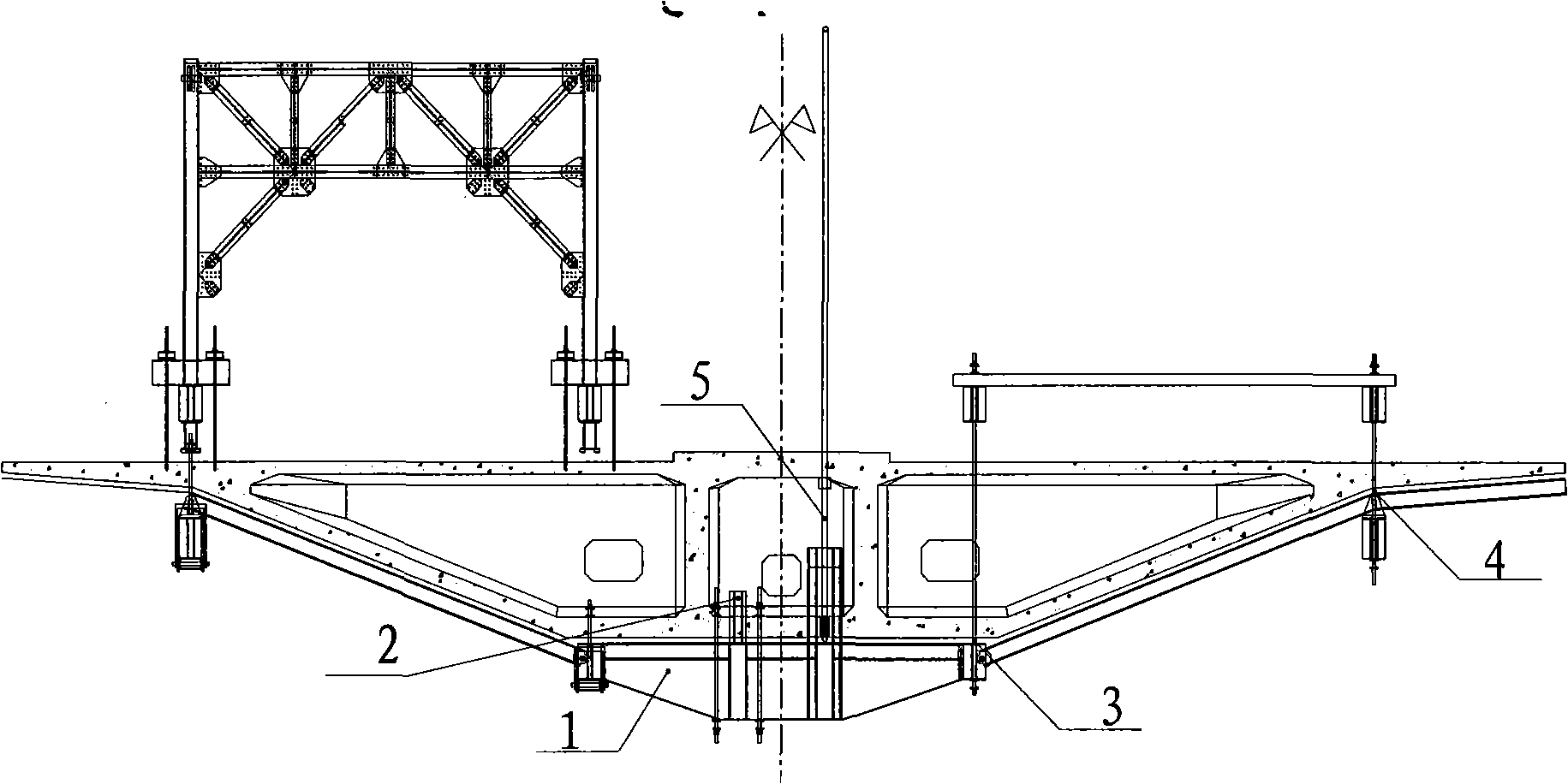

[0024] Such as figure 1 As shown, the present invention is respectively provided with strain gauges on the front tie beam 1 of the hanging basket, the shearing device 2, the front end 3 of the inner walking beam, the front end 4 of the outer walking beam, and the extension rod 5 of the cable, and these strain gauges pass through the signal line Connected with the electric control cabinet, the electric control cabinet adopts a single-chip microcomputer or PLC, and is equipped with a preset program and an alarm device to detect the signal of each sensor and compare the deformation with the set value. When the deformation exceeds the set value, , the alarm device activates the alarm. The present invention adopts the above-mentioned technical scheme to monitor the stress and deformation of the hanging basket structure in time, prevent the occurrence of malignant accidents, and ensure the construction quality and construction safety.

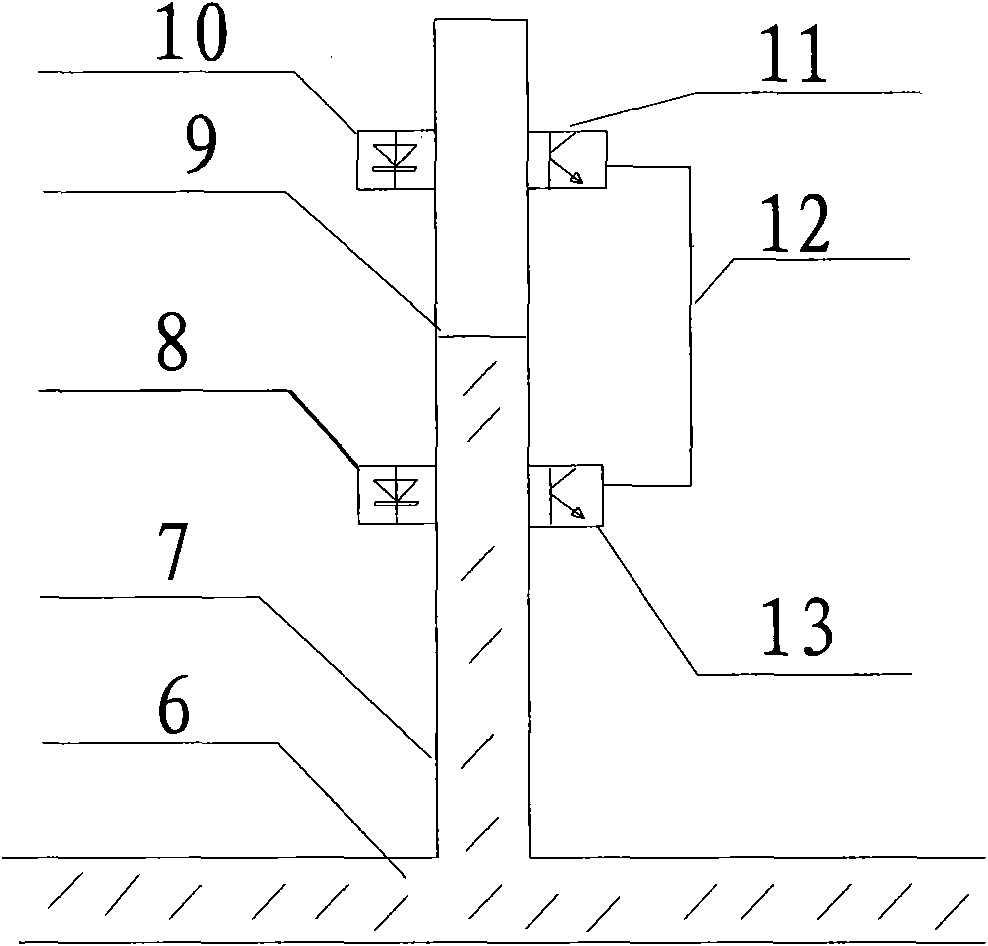

[0025] Such as figure 2 As shown, the level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com