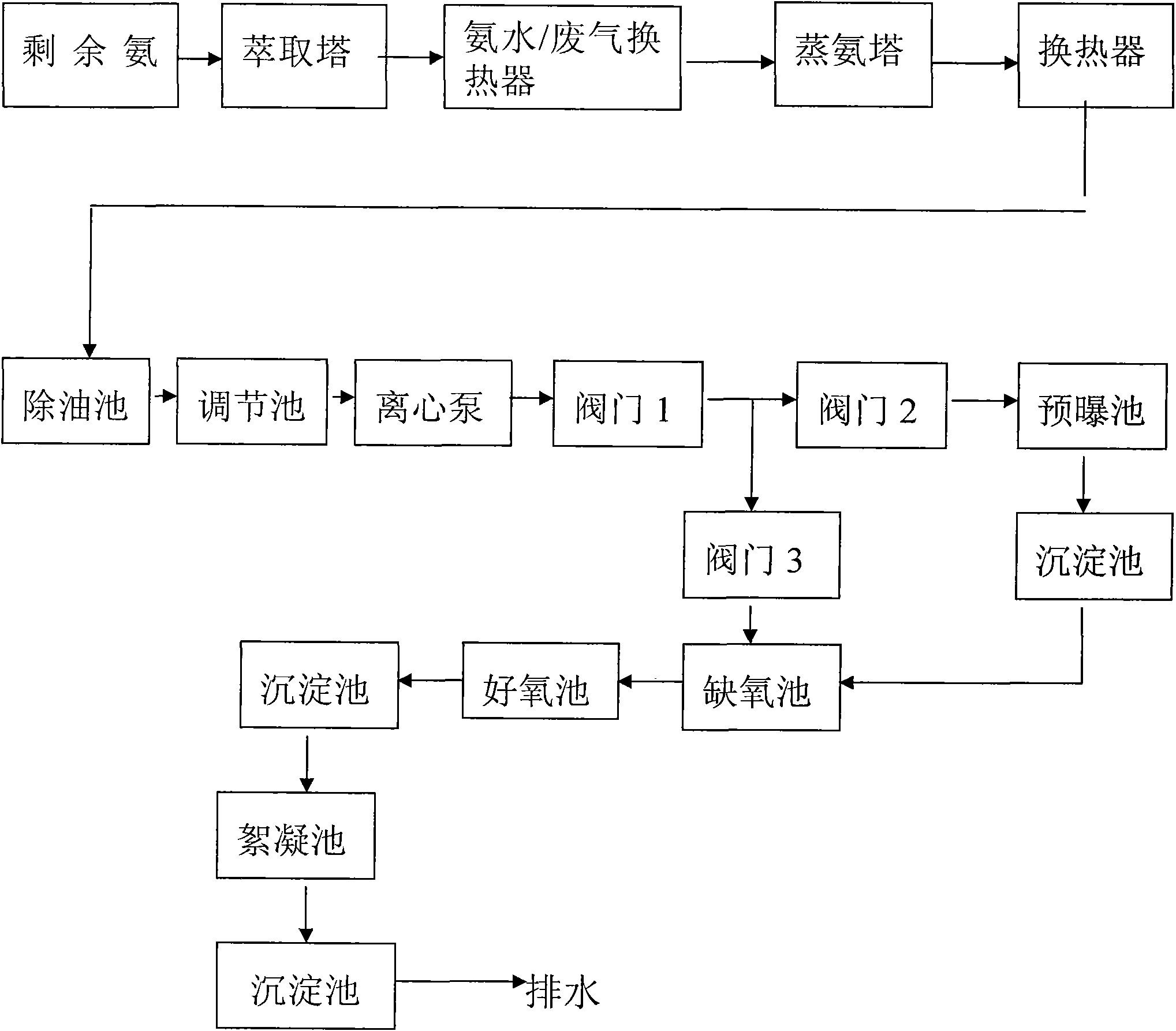

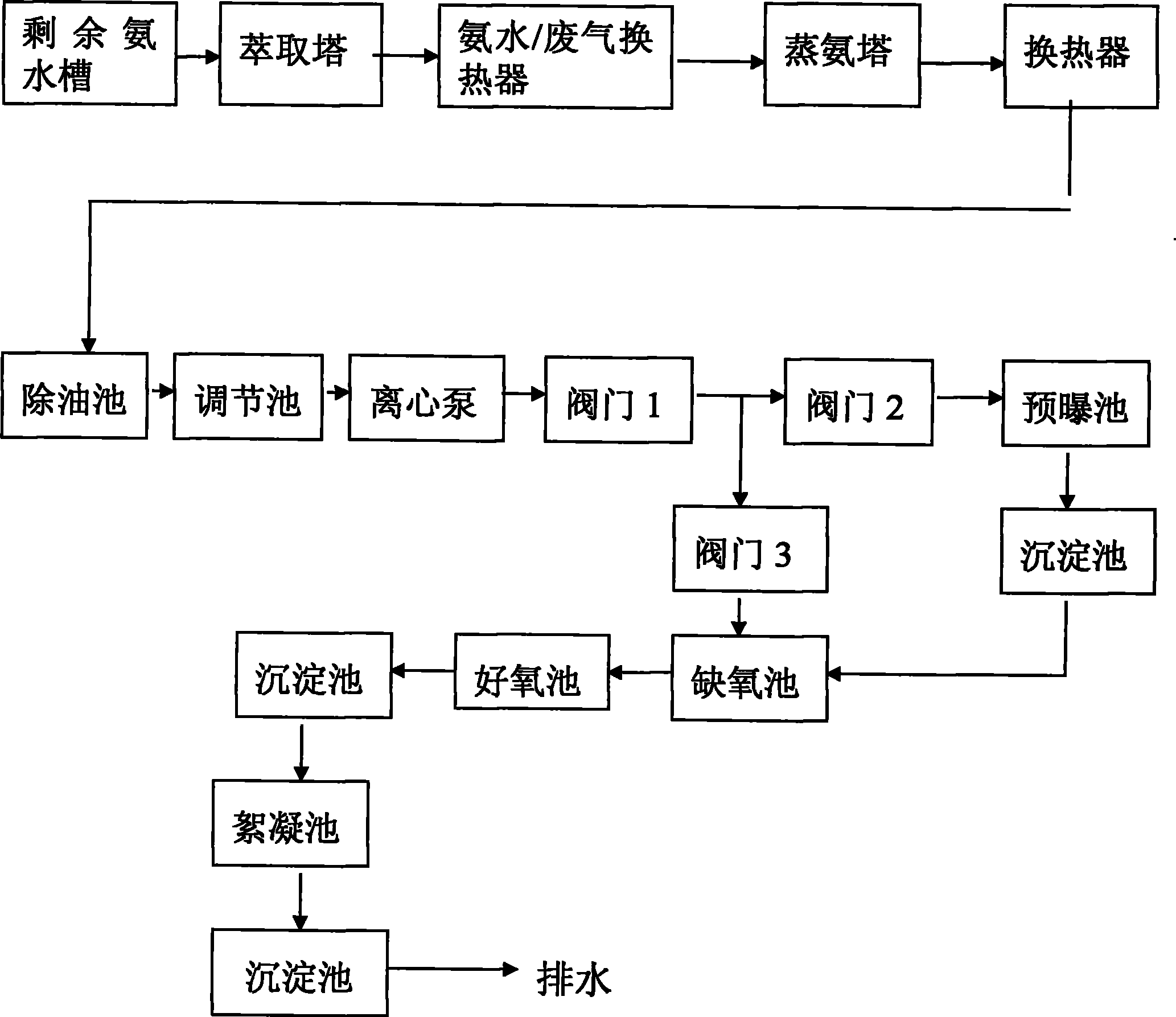

Coking wastewater treatment process

A technology of coking wastewater and treatment process, which is applied in degassed water/sewage treatment, extracted water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of many types of toxic organic substances, high concentration of ammonia nitrogen, and large fluctuations in water quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The remaining ammonia water is pumped to the extraction tower through the remaining ammonia water tank, the flow rate is 220t / h, the COD content is 7200mg / l, the ammonia nitrogen is 1600mg / l, the phenol is 1500mg / l, the cyanide is 50mg / l, and the temperature is 70°C. The ammonia water enters from the upper part of the extraction tower, and the solvent light benzene enters from the lower part of the extraction tower to contact with the ammonia water reversely. The tar and phenol in the ammonia water are partially extracted. After coming out of the extraction tower, the COD content is 6500mg / l, and the ammonia nitrogen is 1600mg / l Phenol is 480 mg / l and cyanide is 45 mg / l.

[0014] After the ammonia water is extracted, it flows into the middle tank of ammonia water, and is pumped to the ammonia water / exhaust gas heat exchanger. After the temperature of the wastewater is preheated to 90°C, it enters the ammonia distillation tower for ammonia distillation. The internal press...

Embodiment 2

[0017] The remaining ammonia water is pumped to the extraction tower through the remaining ammonia water tank. The flow rate is 270t / h, the COD content is 7000mg / l, the ammonia nitrogen is 1500mg / l, the phenol is 1700mg / l, and the cyanide is 50mg / l. After reverse contact with benzene, the COD content is 6300mg / l, the ammonia nitrogen is 1500mg / l, the phenol is 490mg / l, the cyanide is 38mg / l, the temperature is 70°C, and the temperature rises to 89°C after passing through the ammonia water / exhaust gas heat exchanger. Enter the ammonia distillation tower to distill ammonia, the pressure inside the tower is 26kPa, the fixed ammonia in the water is converted into free ammonia under the action of NaOH, and is evaporated together with the free ammonia in the ammonia water, and the wastewater flow rate after ammonia distillation is 275t / h. , the COD3500 content is mg / l, the ammonia nitrogen content is 240mg / l, the phenol is 430mg / l, the cyanide is 28mg / l, and the temperature after hea...

Embodiment 3

[0020]The remaining ammonia water is pumped to the extraction tower through the remaining ammonia water tank, the flow rate is 300t / h, the COD content is 7200mg / l, the ammonia nitrogen is 1700mg / l, the phenol is 1500mg / l, the cyanide is 45mg / l, and the temperature is 70°C. After the extraction tower is in reverse contact with light benzene, the COD content is 6800mg / l, the ammonia nitrogen is 1680mg / l, the phenol is 500mg / l, and the cyanide is 45mg / l. Ammonia distillation in the ammonia tower, the pressure inside the tower is 28kPa, the fixed ammonia in the water is converted into free ammonia under the action of NaOH and is evaporated together with the free ammonia in the ammonia water, the wastewater flow rate after ammonia distillation is 305t / h, COD The content is 3500mg / l, the ammonia nitrogen is 270mg / l, the phenol is 480mg / l, the cyanide is 30mg / l, and the temperature is 40°C after heat exchange by the heat exchanger. The wastewater index is stable for 10 days.

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com