Gas shield welding wire

A technology of gas shielded welding and welding wire, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems such as failure to meet applicable requirements, failure to solve corrosion resistance problems, low low temperature impact toughness, etc., and achieve excellent welding operability , Improve the efficiency of welding operation, the effect of high and low temperature shock absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0029] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the invention, and detailed implementation and test data are provided, but the protection scope of the present invention is not limited to the following embodiments.

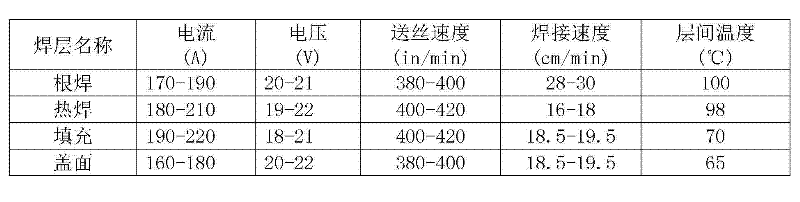

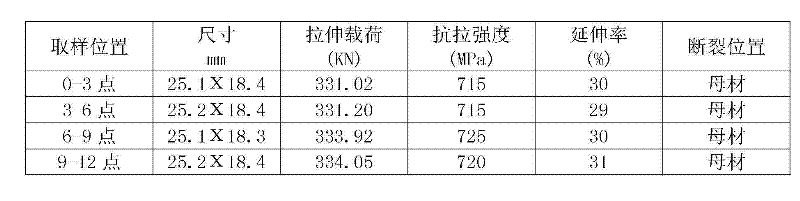

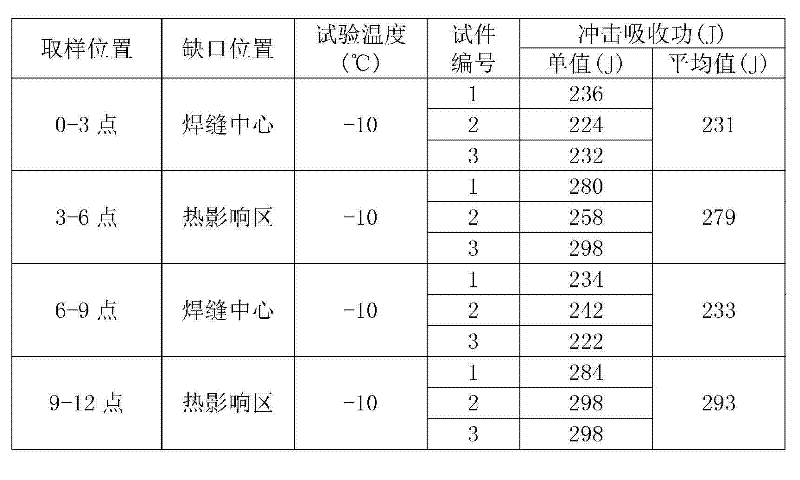

[0030]A gas shielded welding wire whose Pcm is 0.226, nickel+molybdenum+titanium is 0.69%, and Mn / (Si+P) is 2.58 is selected, and its specific composition percentage is expressed as: C: 0.10; Si: 0.58; Mn: 1.53 ; P: 0.013; S: 0.005; Cr: 0.032; Ni: 0.337; Mo: 0.271; Ti: 0.083; Cu: 0.08; This welding consumable is used in the test for a pipe made of API X80, with a diameter of φ1219mm and a wall thickness of 18.4mm. The welding method is gas metal arc welding (GMAW), and the welding direction is downward, which is used for root welding, heat welding, filling welding and cover welding respectively. The welding parameters are as follows:

[0031]

[...

Embodiment 2)

[0048] A gas shielded welding wire whose Pcm is 0.223, nickel+titanium+boron is 0.87%, and Mn / (Si+P) is 3.32 is selected, and its specific composition percentage is expressed as: C: 0.07; Si: 0.53; Mn: 1.8 ; P: 0.013; S: 0.006; Cr: 0.024; Ni: 0.75; Mo: 0.008; Ti: 0.108; Cu: 0.17; This welding consumable is used in the test for a pipe made of API X80, with a diameter of φ1219mm and a wall thickness of 18.4mm. The welding method is gas metal arc welding (GMAW), and the welding direction is downward, which is used for root welding, heat welding, filling welding and cover welding respectively. The welding parameters are as follows:

[0049]

[0050] Appearance Inspection and Radiographic Inspection:

[0051] project

in conclusion

project

in conclusion

width

13-13.5mm

Stomata

none

Yu Gao

1.7mm

none

Wrong Side

0.5mm

none

crack

none

Concave

none

Inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com