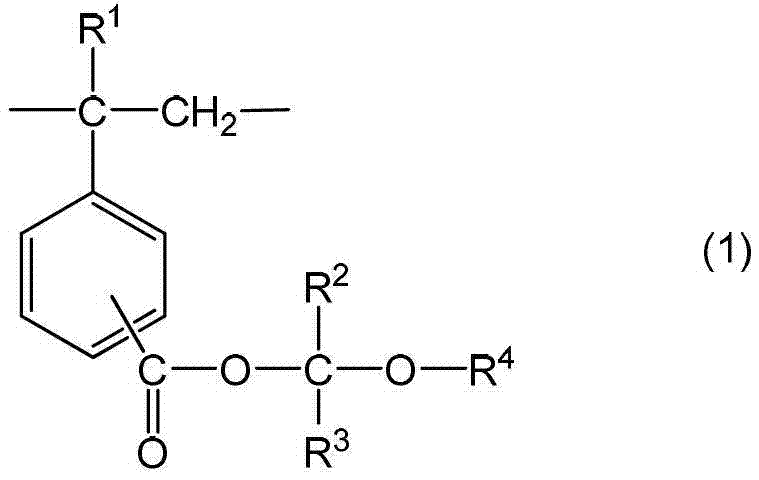

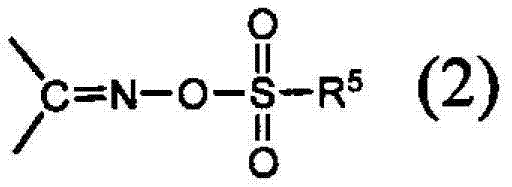

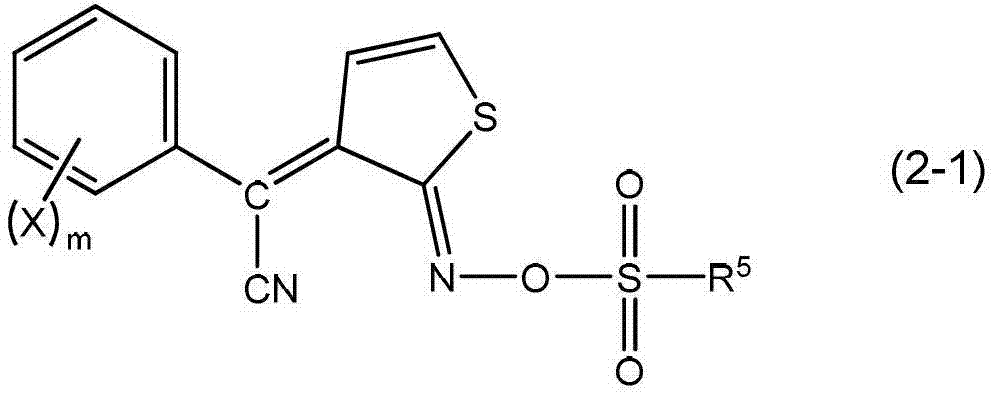

Positive photo-sensitive resin composition and solidification film forming method using same

A photosensitive resin and composition technology, applied in the field of cured film formation, positive photosensitive resin composition, can solve the problems of low transmittance, insufficient adhesion and transmittance, unsatisfactory, etc. Excellent efficiency and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0266] The preparation method of the composition solution: according to the prescribed ratio, the (A) component, (B) component, (C) component and other ingredients are mixed and stirred to dissolve by any method to prepare the composition solution. For example, a composition solution may be prepared by dissolving various components in a solvent in advance to prepare a solution, and then mixing these solutions at a predetermined ratio. The composition solution thus prepared can also be used after being filtered through a filter having a pore diameter of 0.2 μm or the like.

[0267]

[0268]A desired coating film can be formed by applying a composition solution on a predetermined substrate and removing the solvent by heating (hereinafter referred to as "prebaking"). Examples of the above-mentioned substrate include a glass plate provided with a polarizing plate, a black matrix layer and a color filter layer provided as necessary, and a transparent conductive circuit layer in t...

Embodiment

[0280] The present invention will be described in more detail below by way of examples. However, the present invention is not limited to these examples.

Synthetic example 1

[0281] (Synthesis Example 1: Synthesis of A1-1)

[0282] Put 89.4g (0.36 mole) p-(1-n-butoxyethoxycarbonyl) styrene, 21.1g (0.12 mole) benzyl methacrylate, 17.8g (0.12 mole) p-ethylene into a 500mL three-necked flask benzoic acid and 300mL methyl isobutyl ketone, to which a catalytic amount of 2,2'-azobis(2-methyl propionate) was added as a free radical polymerization initiator, under nitrogen flow at 80°C Polymerization was 6 hours. After cooling the reaction liquid, a large amount of heptane was injected to precipitate a polymer. After the crystals were collected by filtration, they were dissolved in diethylene glycol ethyl methyl ether, and the heptane and methyl isobutyl ketone contained in the solution were distilled off under reduced pressure to obtain polymer A1-1 (p-( 1-n-butoxyethoxycarbonyl)styrene / benzyl methacrylate / p-vinylbenzoic acid) in diethylene glycol ethyl methyl ether.

[0283] The molecular weight and molecular weight distribution of the obtained polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com