LED light source module

An LED light source and module technology, applied in the field of LED lighting, can solve the problems affecting the excitation efficiency and life of phosphors, short life of LED light-emitting modules, low light extraction efficiency, etc., and achieves lower temperature, simple structure, and high light extraction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

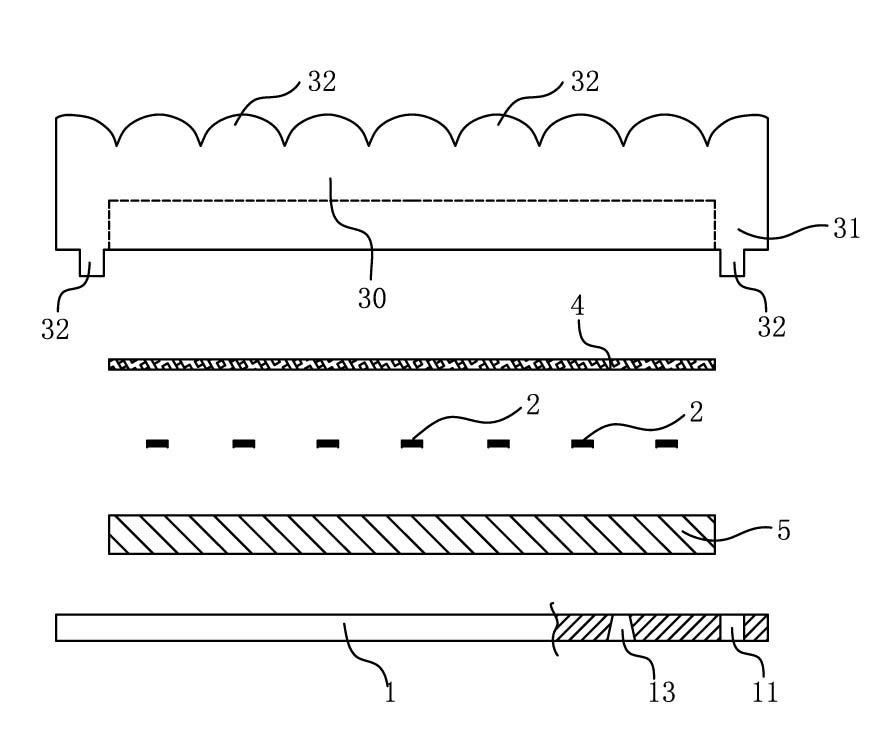

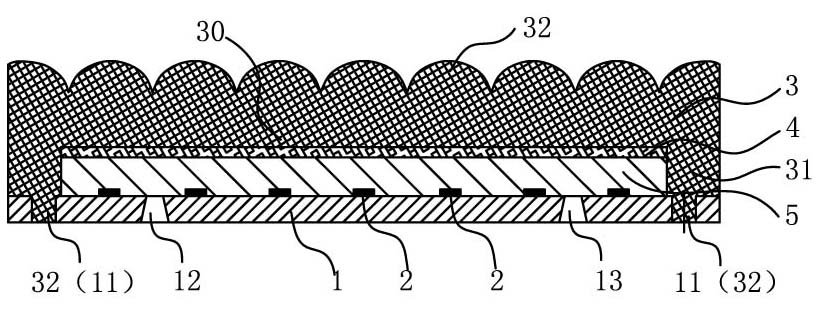

[0024] Depend on figure 1 and figure 2 It can be seen that an LED light source module provided in this specific embodiment includes: a substrate 1 , an LED light-emitting chip 2 , a lens module 3 , a phosphor layer 4 , and a filling body 5 . In this embodiment, the substrate 1 is a rectangular thin plate. There are multiple LED light-emitting chips 2 arrayed on one side surface (upper surface) of the substrate 1 . The lens module 3 includes a main body 30 , a frame 31 , and several lens units 32 . The main body 30 is rectangular, and its edges extend to one side (lower side) to form the rectangular frame 31 . The substrate 1 is covered on the outer side (opening side) of the frame 31 , and forms a closed rectangular box with the lens module 3 ; the LED light-emitting chip 2 is located in the rectangular box. One side (upper surface) of the main body of the lens module 3 has multiple protrusions, and each protrusion is actually a lens unit 32 , and the position of the lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com