Lithium cobaltate composite oxide coated by hydrolytic precipitation-roasting method and manufacturing method thereof

A technology for coating lithium cobaltate and composite oxides, which is applied in the field of new energy material preparation, can solve the problems of failure to meet the requirements of commercial applications, complicated operation process, and inability to use, so as to improve cycle stability and anti-overshooting. The effect of charging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Zr 4+ The preparation of solution: 177.7g Zr(SO 4 ) 2 4H 2 O was dissolved in 500mL of pure water, and the resulting aqueous solution was diluted to 1000mL to prepare 0.5mol / L Zr 4+ solution.

[0035] Weigh 20kg CoCO 3 (particle size D 50 2μm) and 6.99kg LiOH·H 2 O (particle size D 50 2μm), the Li / Co (molar ratio) of the ingredients is 0.99, after mixing thoroughly by dry method. The mixture was first fired at 600°C for 8 hours and then at 1100°C for 3 hours. Pulverize and classify the synthesized product to obtain LiCoO to be coated 2 . XRD analysis showed that the LiCoO 2 With standard α-NaFeO 2 Layered structure. The measured tap density is 2.55g / cm 3 , BET specific surface area is 0.43m 2 / g, particle size D 50 is 7.2 μm.

[0036] Get the above prepared 0.5mol / L Zr 4+ Put 10.2mL of the solution in a 2L reactor with a stirring device, add water to dilute to 1000mL, take 1000g of the LiCoO prepared above 2 Add it into the reactor, stir for 5 minutes...

Embodiment 2

[0046] Get the prepared Zr of embodiment 1 4+ Put 1021.5mL aqueous solution in a 2L reactor with stirring device, add pure water to dilute to 1000mL, take 1000g of LiCoO to be coated prepared in Example 1 2 Add it into the reactor, stir for 5 minutes, adjust the pH value to 10.0 with 10% (wt.) NaOH solution, and filter.

[0047] The precursor obtained by the above filtration was calcined at 1000 °C for 3 hours to obtain the coated LiCoO 2 composite oxides.

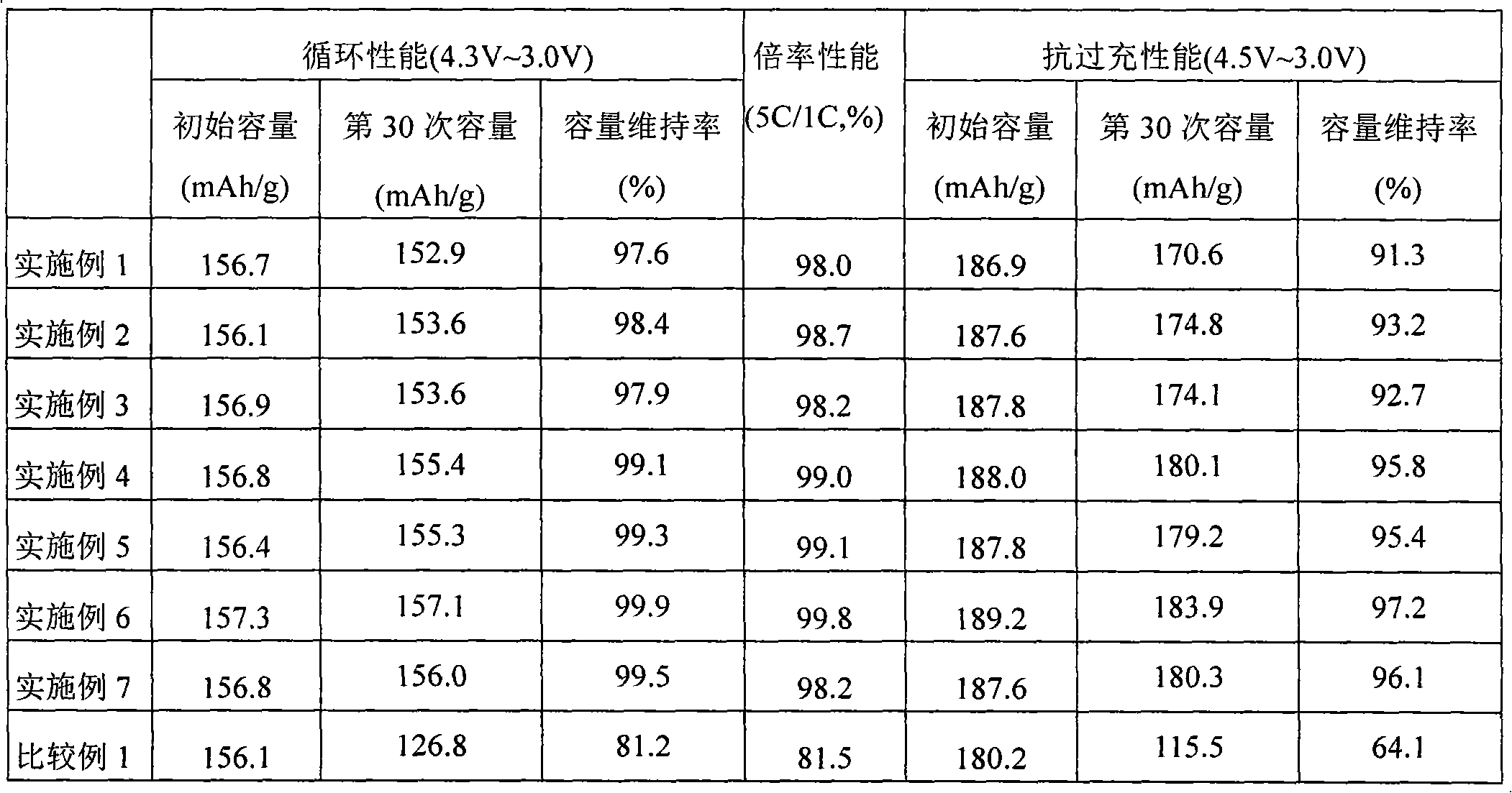

[0048] Analysis showed that the coating layer on the surface of the product particles had a thickness of about 35nm. Other physical properties of the product are listed in Table 1. According to the method of Example 1, the electrical performance indicators of the product when it is a positive electrode active material are listed in Table 2.

Embodiment 3

[0050] Ti 4+ Solution preparation: 120.0g Ti(SO 4 ) 2 Dissolve in 500mL of 5% (wt.) dilute sulfuric acid solution, dilute the resulting aqueous solution to 1000mL, and prepare 0.5mol / L Ti 4+ solution.

[0051] Take the Ti prepared above 4+ 10.2 mL of the solution was placed in a 2L reactor with a stirring device, diluted to 1000 mL with pure water, and 1000 g of the LiCoO to be coated prepared in Example 1 was taken. 2 Add it into the reactor, stir for 5 minutes, adjust the pH value to 8.0 with 10% (wt.) NaOH solution, and filter.

[0052] The precursor obtained by the above filtration was calcined at 650 °C for 20 hours to obtain titanium-coated LiCoO 2 composite oxides.

[0053] XRD analysis shows that the product has standard α-NaFeO 2 Layered structure. X-ray photoelectron spectroscopy comprehensive analysis shows that after the above method, in LiCoO 2 A layer of LiCo with a thickness of about 15 nm is formed on the particle surface 1-y Ti y o 2(0<y≤1) a compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com