Method for directly testing speed diversity factor and stagnant rate of turbine electro-hydraulic control system

A technology of electro-hydraulic control system and test method, which is applied in the direction of engine test, machine/structural component test, measuring device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

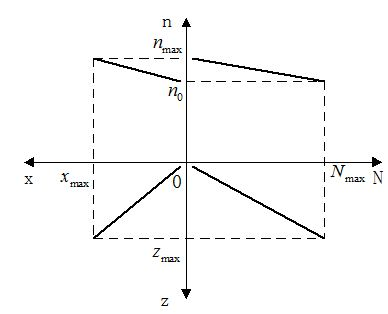

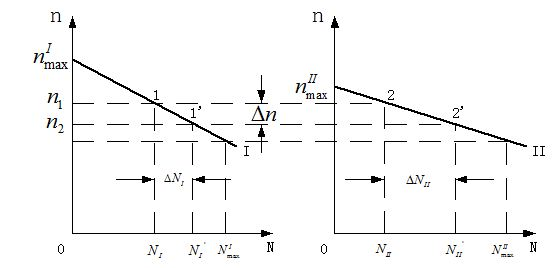

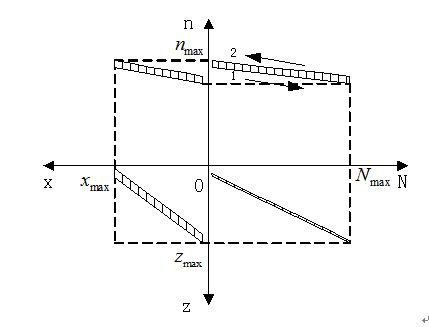

[0065] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0066] Precondition of the inventive method is:

[0067] 1. The turbine generator is connected to the grid, and the grid cycle is relatively stable;

[0068] 2. The main steam pressure, main steam temperature, reheat steam temperature and vacuum of the unit are near the rated value and remain basically stable.

[0069] 3. The heat recovery and steam extraction system of the unit is normally put into operation.

[0070] 4. The unit operates under the condition of single valve or sequence valve (choose to operate under normal condition).

[0071] 2. The specific steps of the test are:

[0072] 1) Determine the load measuring points, from empty load to full load, generally no less than 12 measuring points;

[0073] 2) Under the rated load, check that the main steam pressure, temperature and vacuum of the unit are near the rated value and remain stable;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com