Preparation method for novel layered nano PAL flame-retardant material

A technology of layered nano and flame retardant materials, applied in fibrous fillers, chemical instruments and methods, inorganic pigment treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

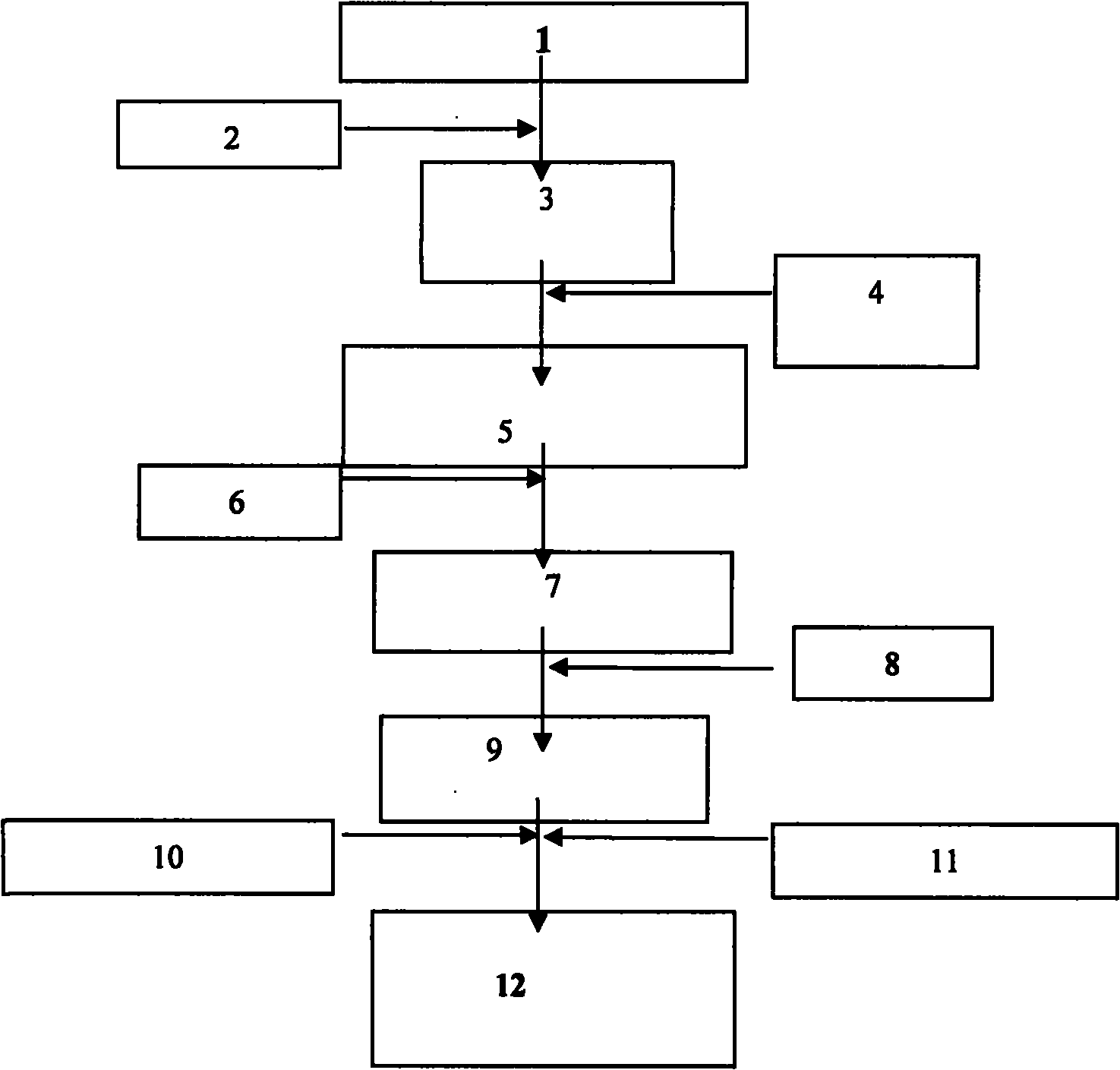

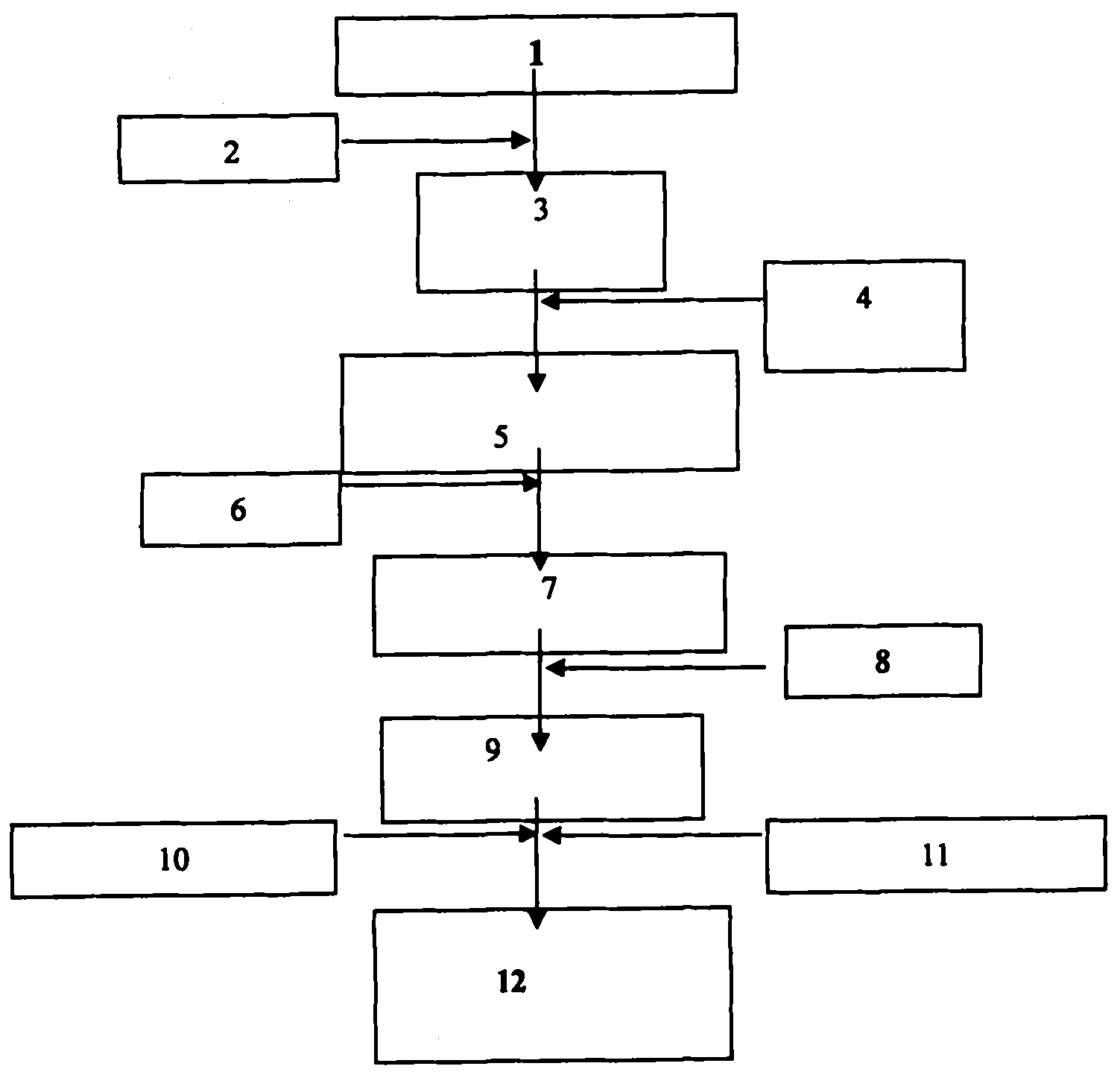

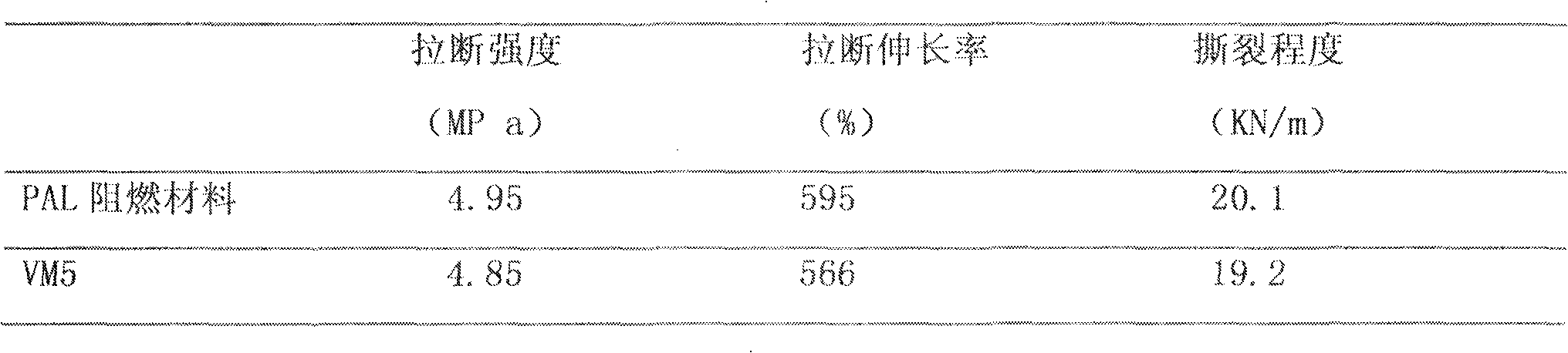

[0012] The present invention will be described in detail below in conjunction with the drawings and specific embodiments: figure 1 As shown, the preparation method of the novel layered nano-PAL flame-retardant material of the present invention is as follows: a. The PAL mineral raw material 1 is beneficiated, crushed and purified 2 to make a 90-98% high-purity PAL material 3; b , The high-purity PAL material 3 is subjected to depolymerization, dispersion, and ultra-micro processing 4 to produce a nano- and sub-micron PAL material 5 smaller than 100-800 nm; c. After the nano- and sub-micron PAL material 5 is inorganically activated 6 Make a large specific surface area nano, sub-micron PAL material 7; d. After organic modification 8 the large specific surface area nano, sub-micron PAL material 7 is made into an organic nano, sub-micron PAL material 9; e, finally The organic nano-, sub-micron PAL material 9 is combined with a polymer matrix 10 to form a polymer layered nano-PAL fla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com