Waste rock discharging and sorting comprehensive treatment method for underground lump coal

A comprehensive processing and sorting technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as waste, pollution, and land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

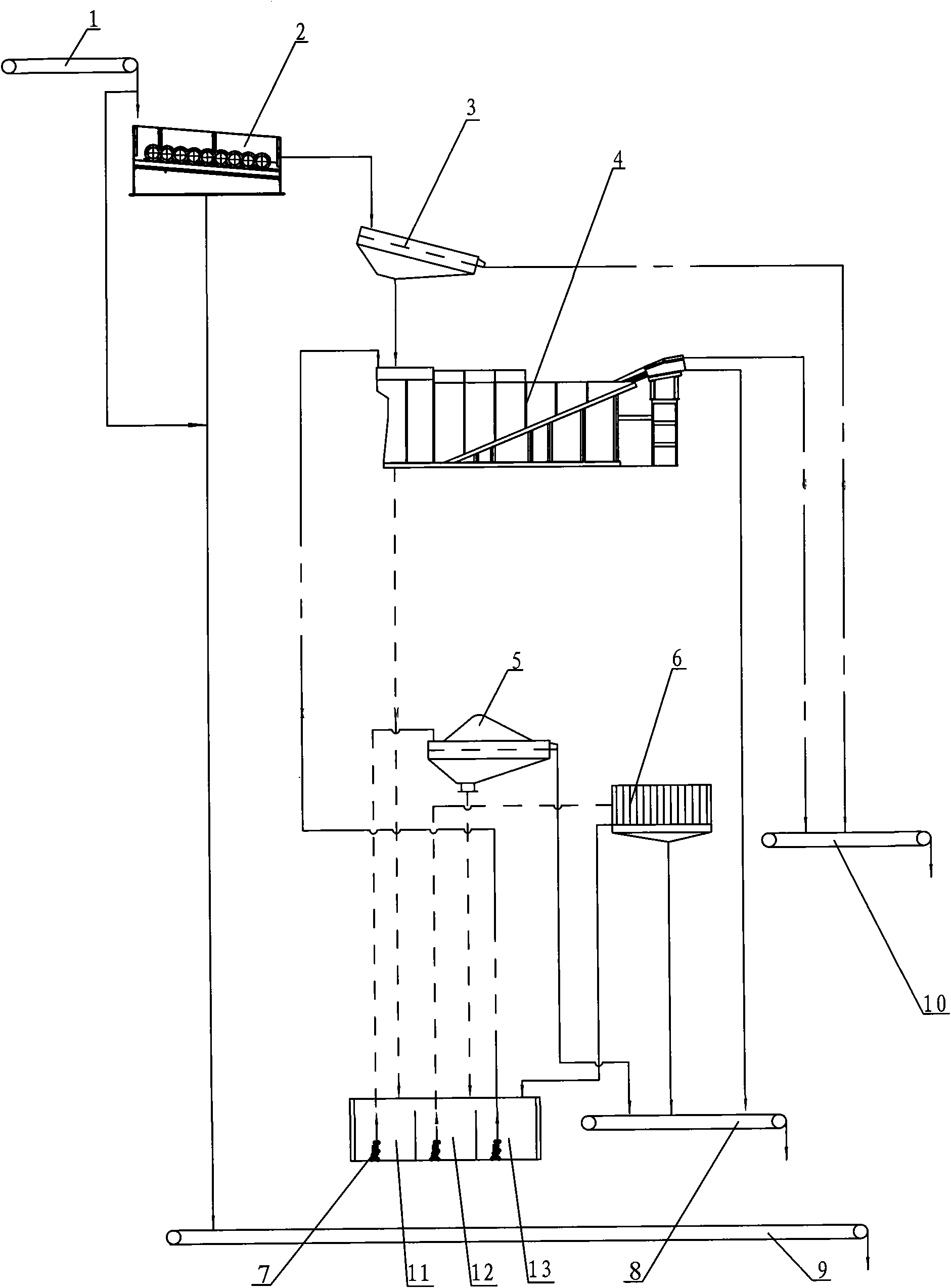

[0014] according to figure 1 The separation process of the present invention will be described in detail. The comprehensive treatment method for underground lump coal separation and gangue separation comprehensively utilizes the mature uphole dynamic screen block coal separation technology and the commonly used rolling disc screen 2, fixed grate screen 3, high-frequency dehydration screen 5 and filter press 6 and other equipment, and configure the mature patented technology "downhole mechanical moving screen jig" (the patent notification number is CN101486012A) that the inventor has used in the underground roadway. Among them, the specifications and models of the rolling screen 2, the high-frequency dehydration screen 5, and the filter press 6 should be selected according to the actual needs of the mining area and the corresponding equipment associated with them. The particle size required for the sorting raw coal of the jig 4 is determined.

[0015] Below is a kind of concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com