Method and apparatus for extracting high-purity nitrogen from air

A high-purity, nitrogen technology, applied in separation methods, chemical instruments and methods, nitrogen purification/separation, etc., can solve problems such as product gas is difficult to meet, purity range is limited, difficult product gas components are stable, etc., and the start-up speed can be improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

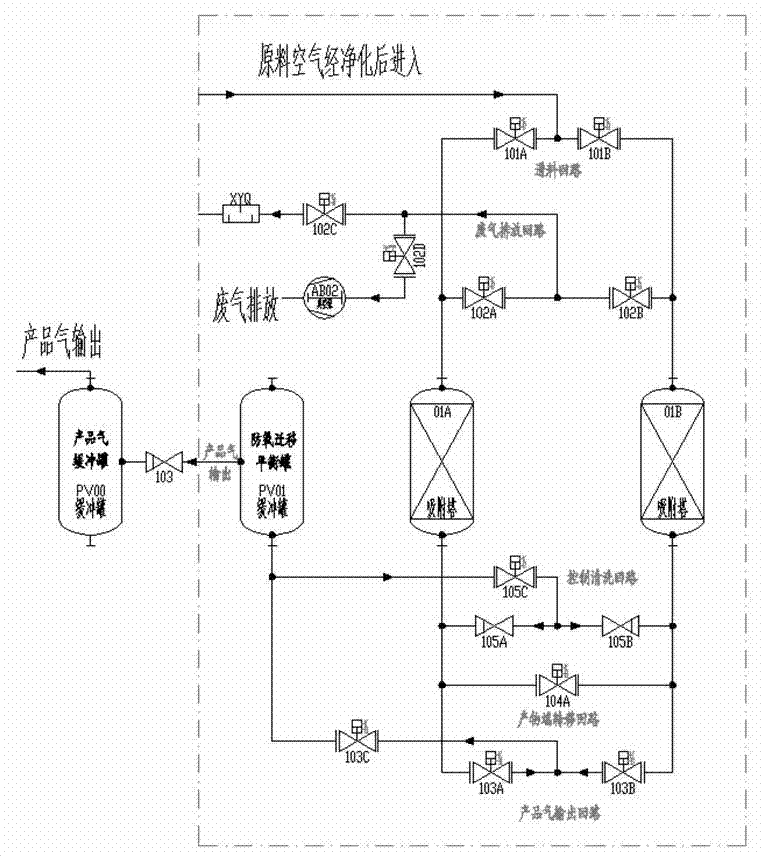

[0057] The method and device of the present invention will be further described below in conjunction with the accompanying drawings.

[0058] as attached figure 1 As shown, the raw material air is pretreated to remove moisture, oil and solid particles in the air and then connected to the feed circuit to realize the fluid switching circuit of the method of the present invention. The circuit is composed as follows:

[0059] 1. The feeding circuit is composed of pneumatic control valves 101A, 101B and necessary connecting pipelines;

[0060] 2. The pressure relief circuit is composed of pneumatic control valves 102A, 102B, 102C, 102D, silencer XYQ, vacuum pump AB02 and necessary connecting pipelines;

[0061] 3. The product gas output circuit is composed of pneumatic control valves 103A, 103B, 103C, check valve 103 and necessary connecting pipelines;

[0062] 4. Circuits and components that control gas transfer and prevent oxygen migration:

[0063] 1) The cleaning circuit fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com