Permanent magnet synchronous motor (PMSM) AC servo system

A technology of permanent magnet synchronous motor and permanent magnet, applied in the field of servo system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] specific implementation plan

[0064] system structure

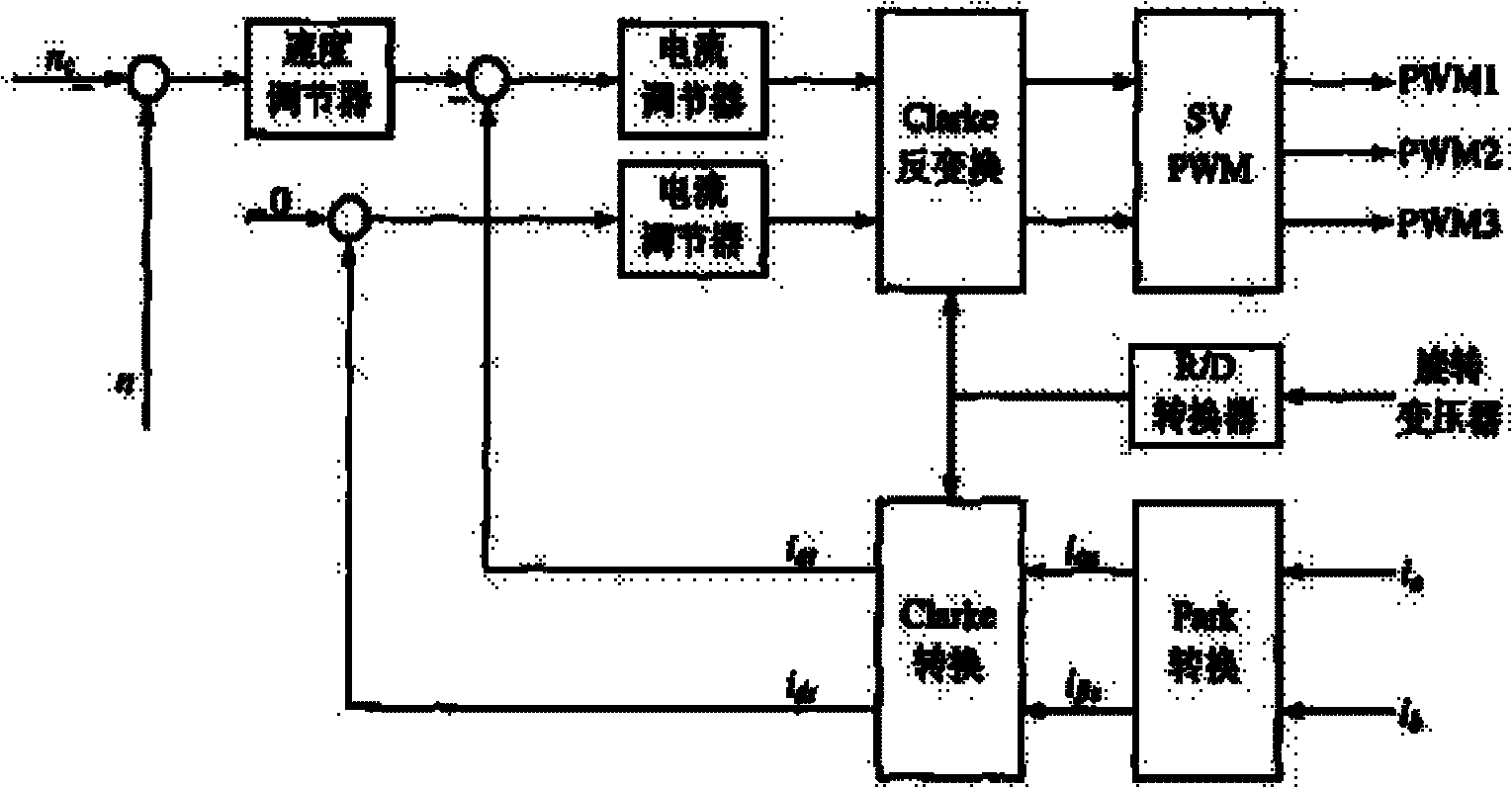

[0065] The key problem of the all-digital PWM frequency converter is how to obtain the PWM control switch signal in time. Normally, there are two control algorithms for obtaining PWM waves, namely, the traditional sub-harmonic PWM (forward rotation PWM) method and the newly proposed current space vector method PWM method. The space current vector control PWM method has obvious advantages in terms of reducing the harmonic loss of the motor current, eliminating torque fluctuations, improving the performance of the control system, or from the aspect of the voltage utilization of the DC side of the inverter.

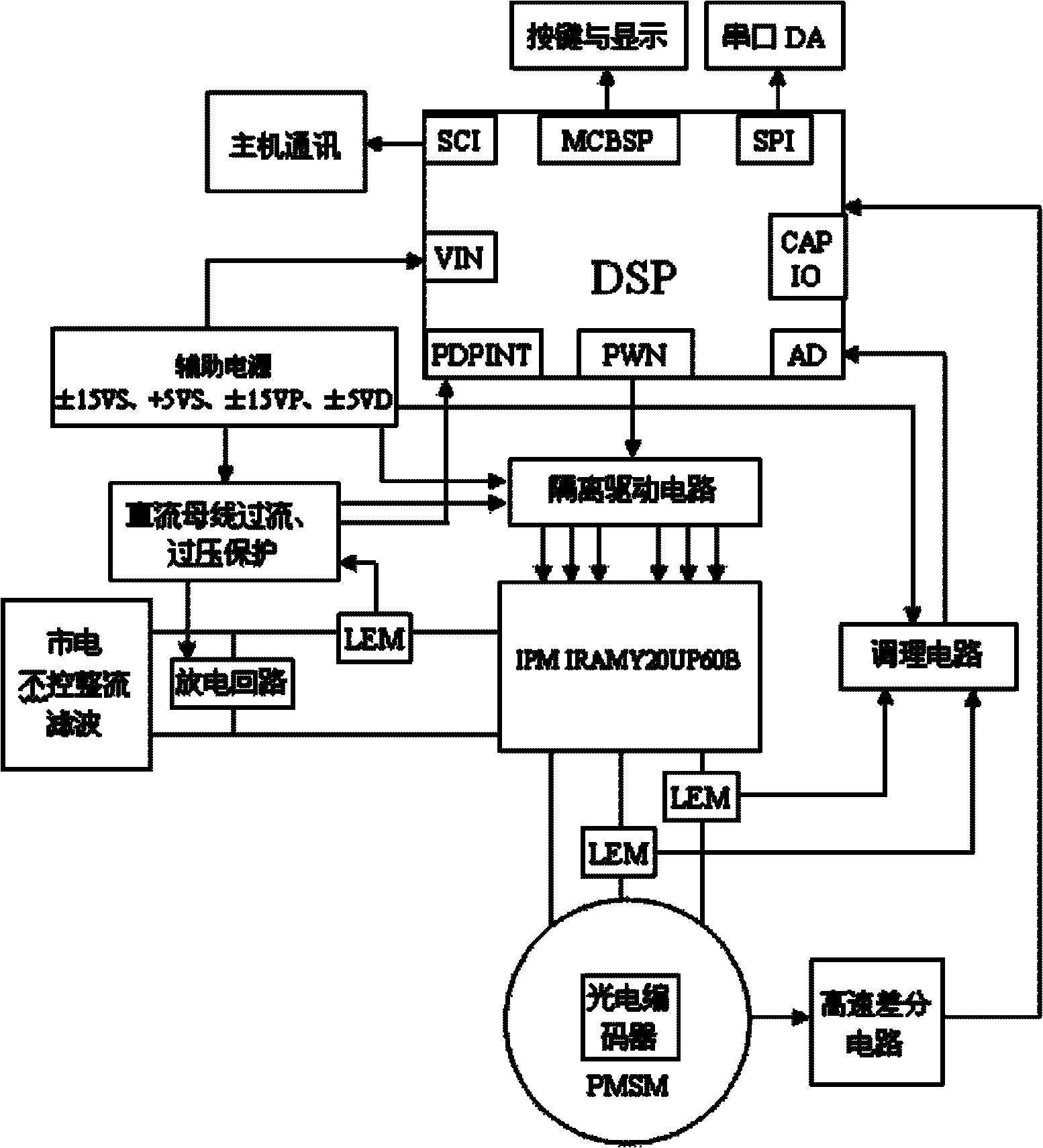

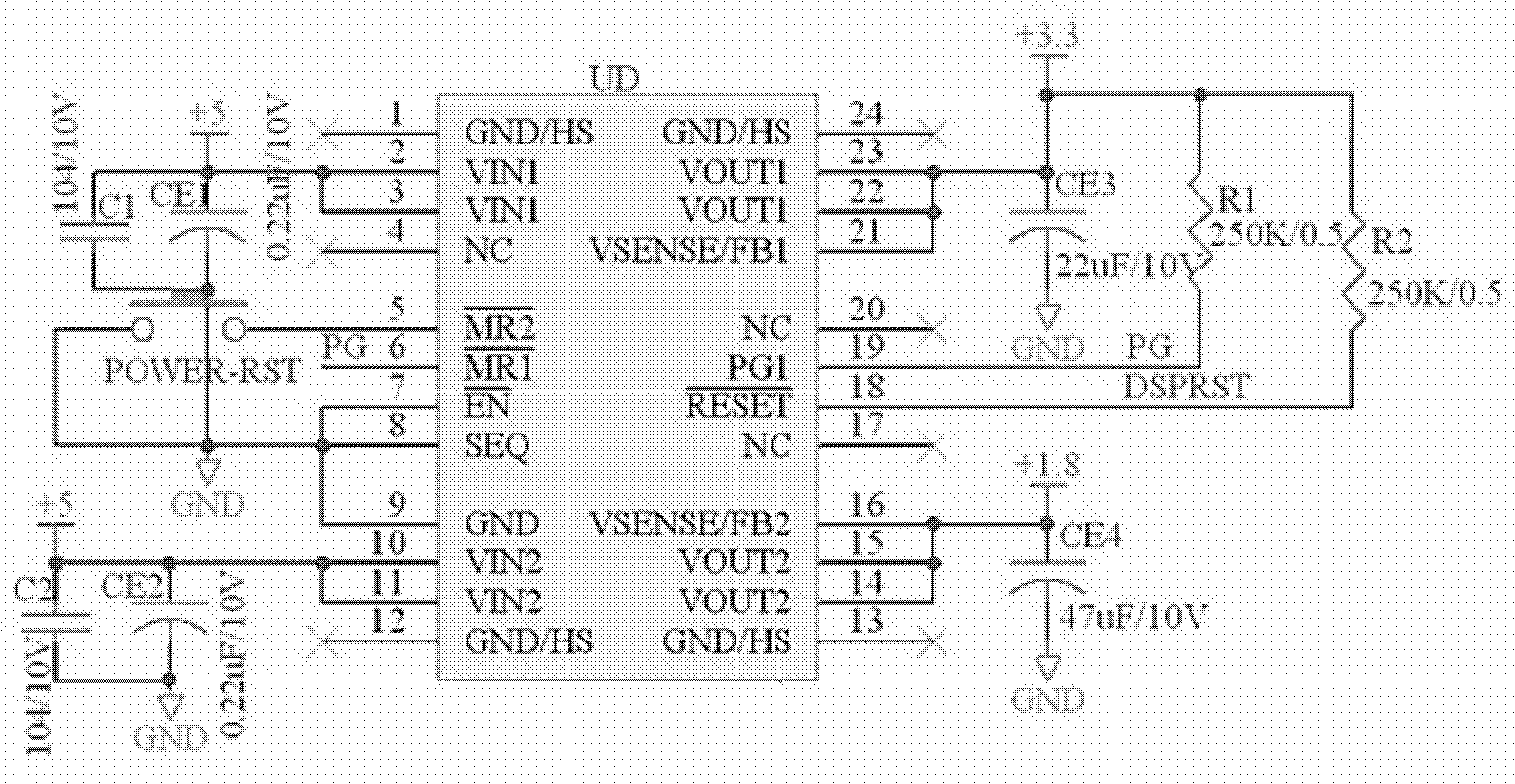

[0066] The application of high-speed digital signal processor (DSP) can make the system develop towards full digitalization with high reliability, high performance and convenient maintenance. TMS320F2812 fixed-point digital signal processor is used as the main control chip to complete the current loop, speed lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com