Illumination device

A lighting device and heat dissipation base technology, applied in lighting devices, lighting device parts, lighting device cooling/heating devices, etc. Device reliability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

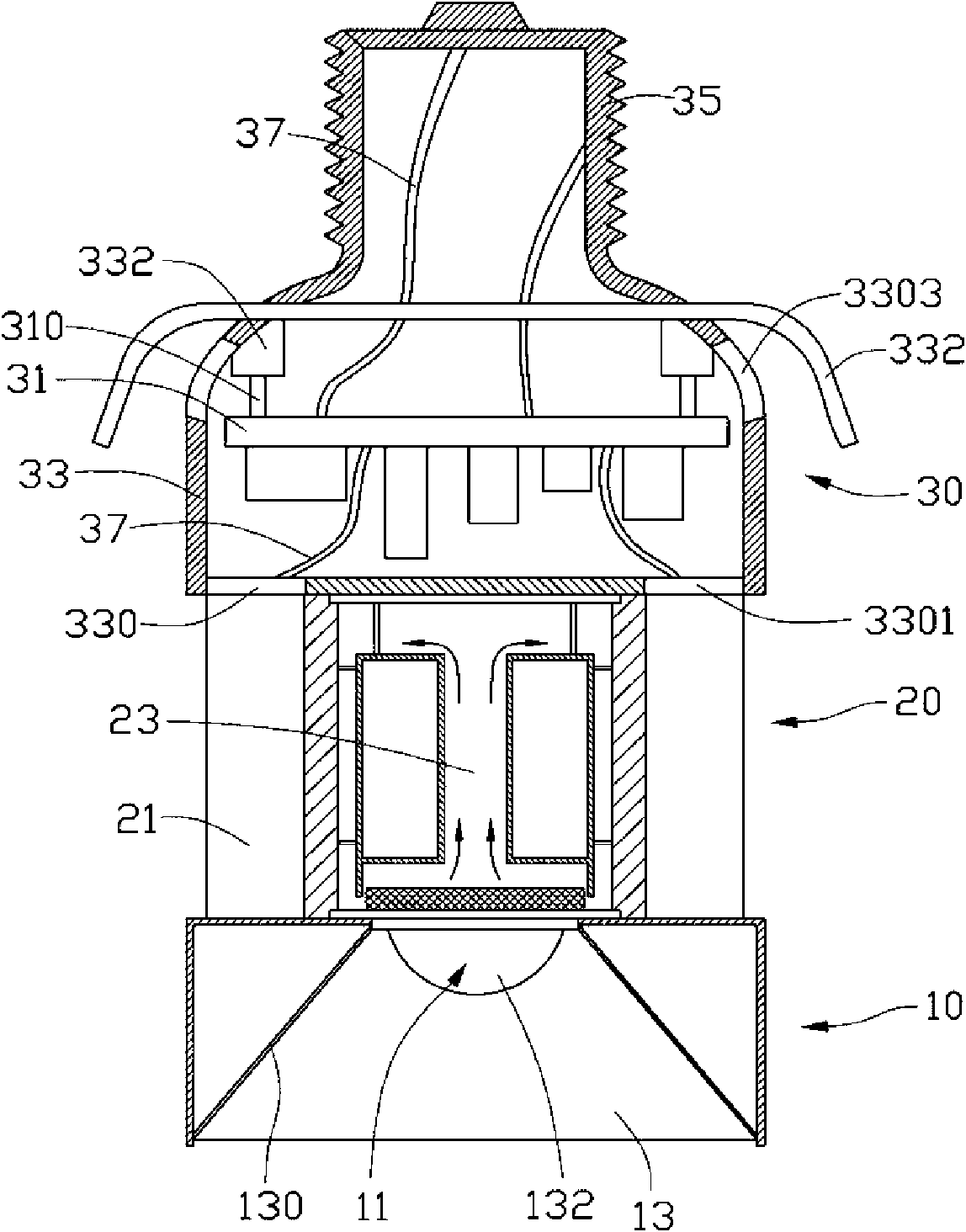

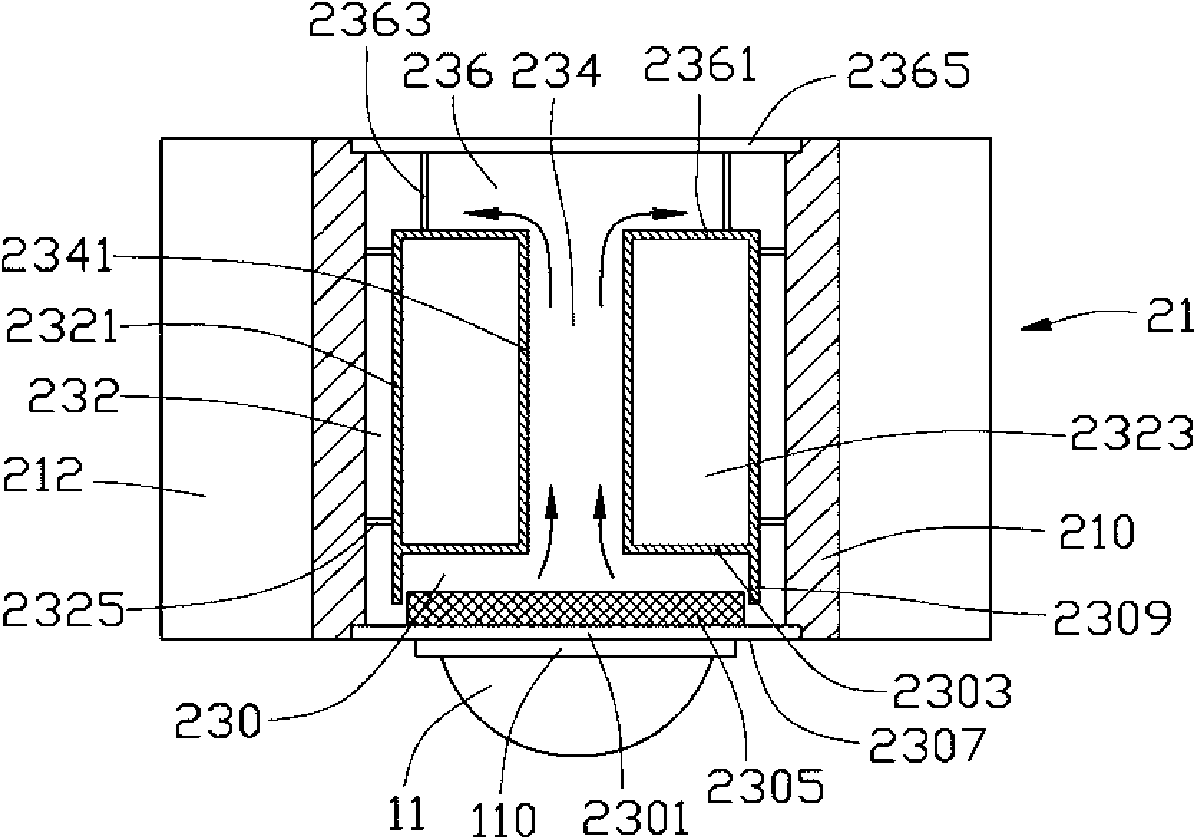

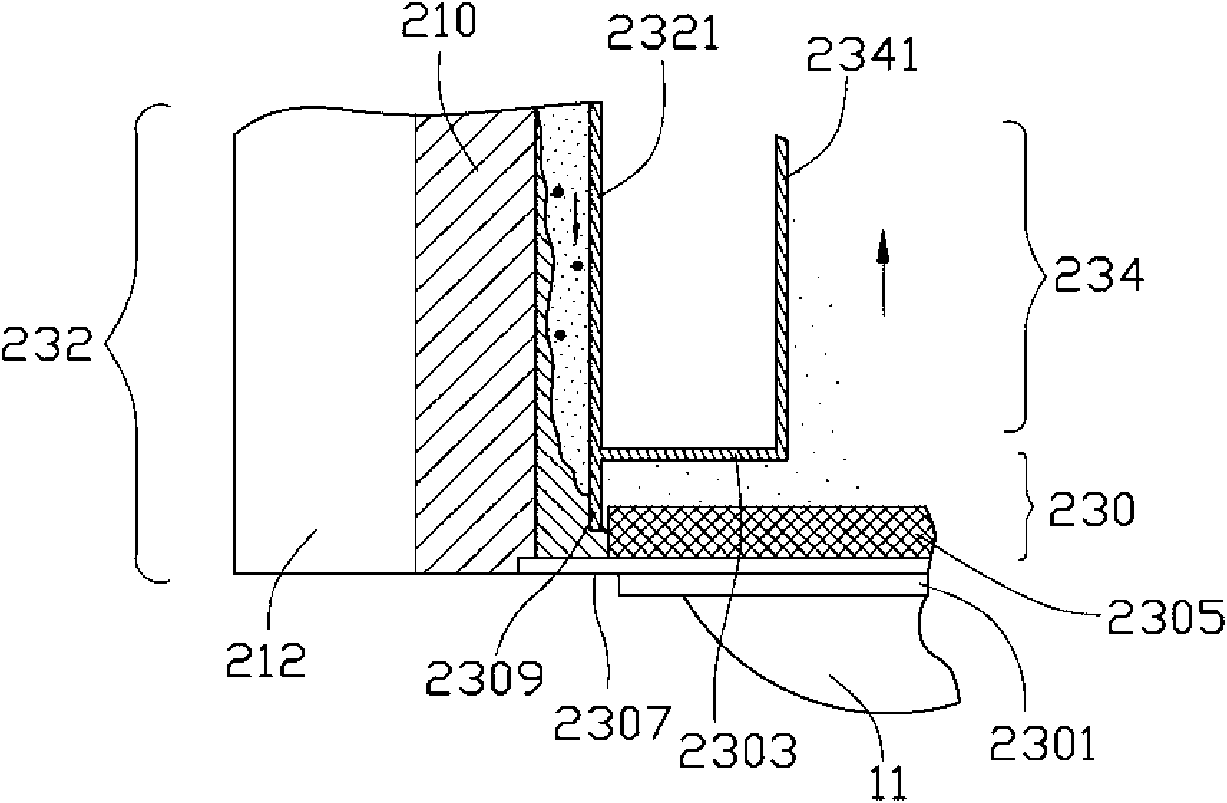

[0022] figure 1 is a schematic cross-sectional view of the assembly of the first embodiment of the lighting device of the present invention, figure 2 yes figure 1 Schematic diagram of the assembly cross-section of the light engine, image 3 yes figure 1 Schematic diagram of the phase change of the working fluid inside the light engine; the lighting device mainly includes an optical part 10 , a heat dissipation part 20 and an electrical part 30 .

[0023] The optical part 10 is arranged under the heat dissipation part 20, and includes at least one light source 11 composed of semiconductor light emitting components (for example, LED) and at least one light exit channel 13. The light source 11 is closely connected to the outer surface of the lower cover 2301 of the heat dissipation part 20 Thermal contact, and a layer of thermal interface material (TIM) can be applied in between, and then several screws (not shown) that have been fitted with electrical insulating gaskets a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com