Superhigh-efficiency anammox reactor

An anaerobic ammonium oxidation and reactor technology, applied in the field of reactors, can solve problems such as insurmountable defects, and achieve the effects of not being easily blocked, reducing matrix toxicity, and improving sludge activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

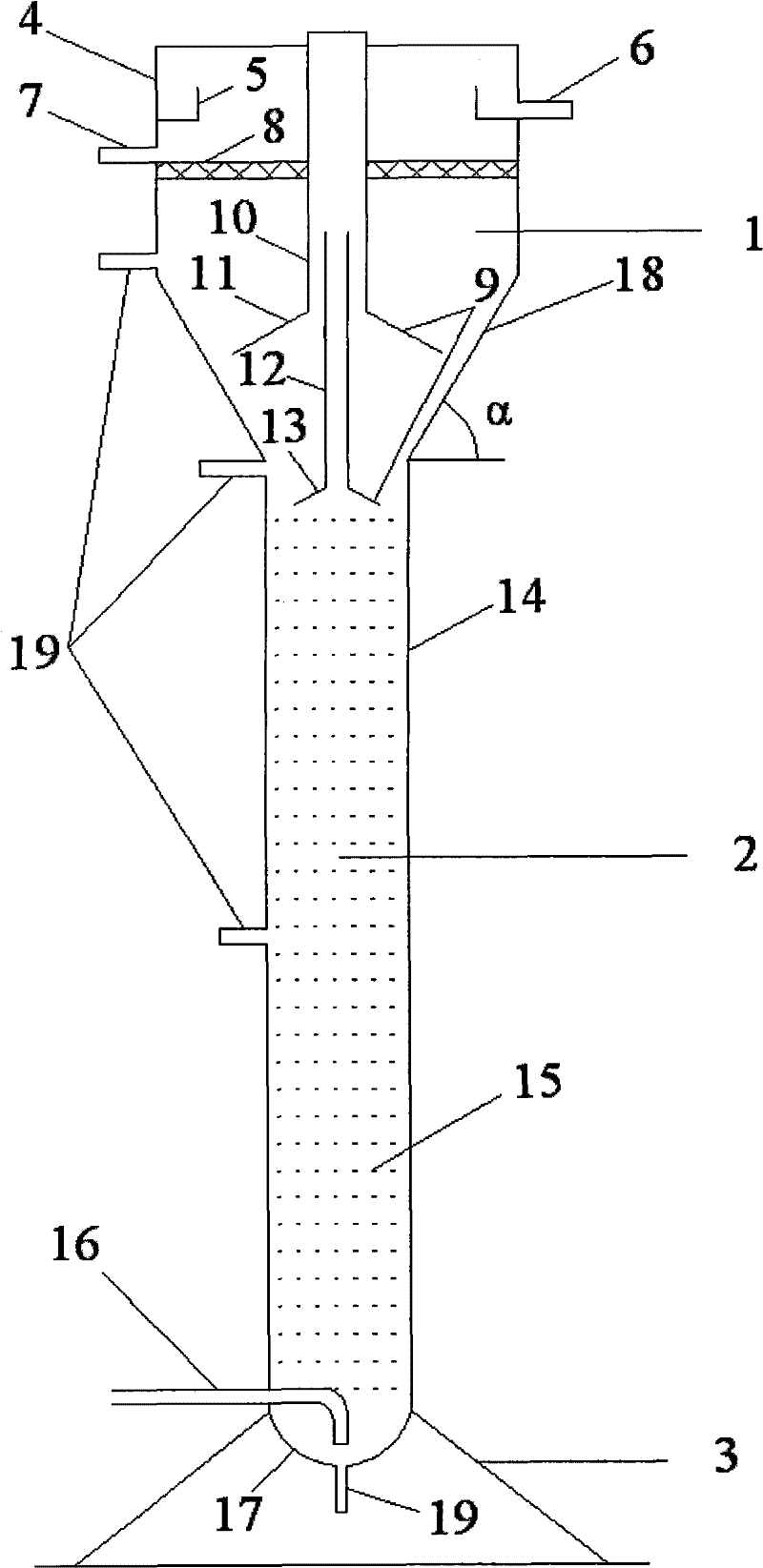

[0020] Example: The ultra-efficient anammox reactor is composed of plexiglass, the diameter of the reaction zone is 10cm, the height is 1m, and the volume is 8L; the diameter of the precipitation zone is 20cm, the height is 34.7cm, and the angle α between the outer cylindrical divergent tube and the reference horizontal plane is 60°, the total volume of the precipitation zone is 8L. The ring-shaped barbed wire has a diameter of 0.5mm, a mesh diameter of 1mm, a diameter of the first gas collecting pipe of 3cm, a diameter of the second gas collecting pipe of 1.5cm, a maximum diameter of the first reducing pipe of 15cm, a maximum diameter of the second reducing pipe of 6cm, and reduced iron powder particle size 100 mesh, the dosage is 1% of the volume of the reaction zone. To simulate the inflow of wastewater, the composition of wastewater: 200mg / L ammonia nitrogen, 240mg / L nitrous nitrogen, and the rest are inorganic nutrients. The operating temperature of the reactor is 35°C, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com