Inner heating furnace

An internal heating and heating device technology, applied in the field of machinery, can solve problems such as affecting the production efficiency of workers, poor working environment, backward heating equipment, etc., and achieve the effects of improving the working environment of workers, good working environment of workers, and reducing heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

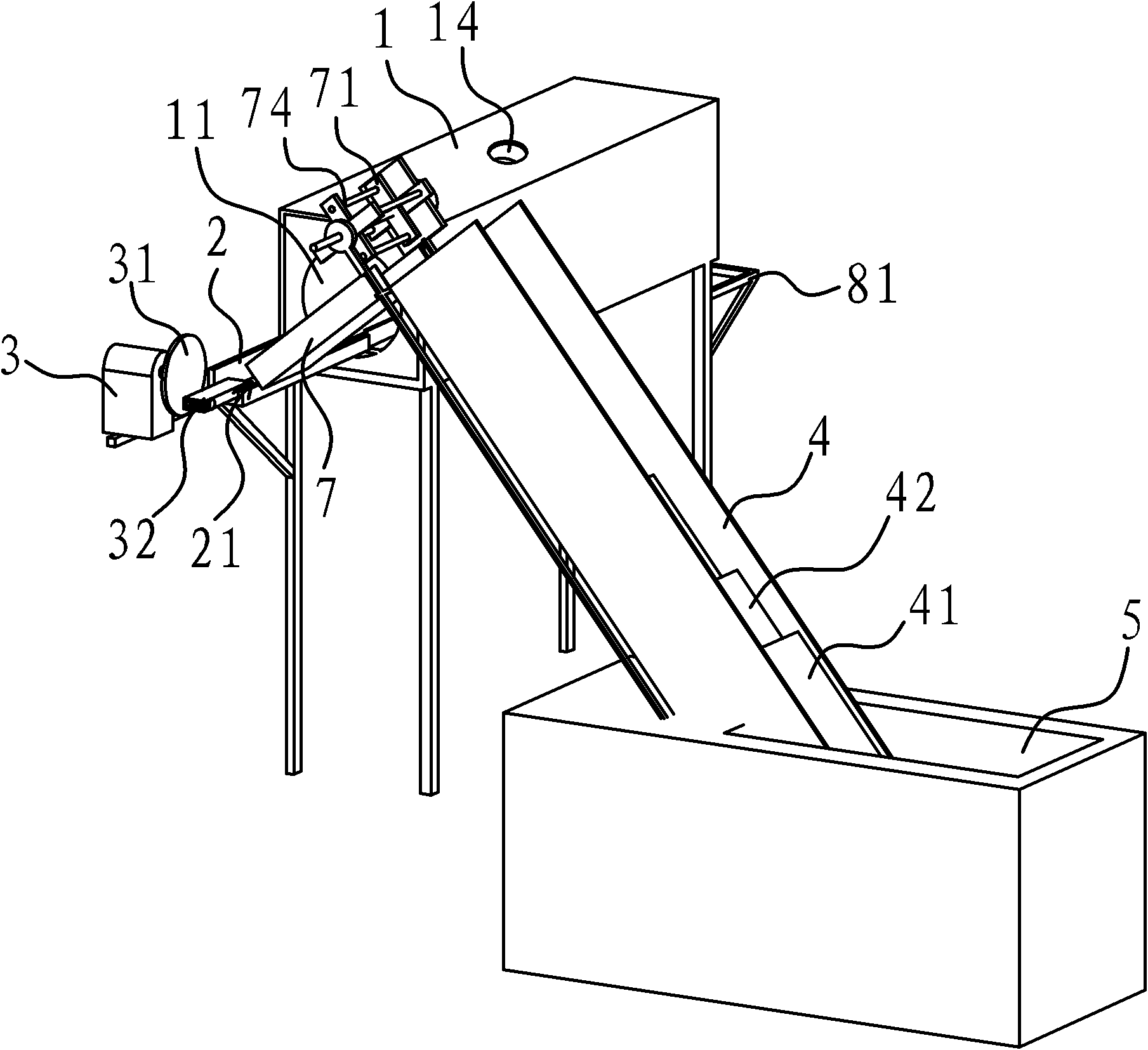

[0036] The internal heating furnace is used for heating the metal blank 9 before forging, and is mainly used for heating the bar of the same type. Such as Figure 1~4 As shown, the internal heating furnace includes a heating device and a furnace body 1 with a feed port 11 and a discharge port 12. The feed port 11 of the furnace body 1 is provided with an automatic feeding mechanism. The conveying device for conveying the billet 9 from the feed port 11 to the discharge port 12 , and the heating device is arranged on the furnace body 1 for heating the billet 9 conveyed in the furnace body 1 .

[0037] The furnace body 1 is in the shape of a cylinder, and its side wall is provided with heat insulating bricks 13. The heating de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com