Preparation method of tin/carbon composite nano fiber film cathode material

A technology of composite nanofiber and thin film materials, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of poor cycle performance and complicated process of composite materials, and achieve improved diffusion behavior, increased specific capacity, and less material consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

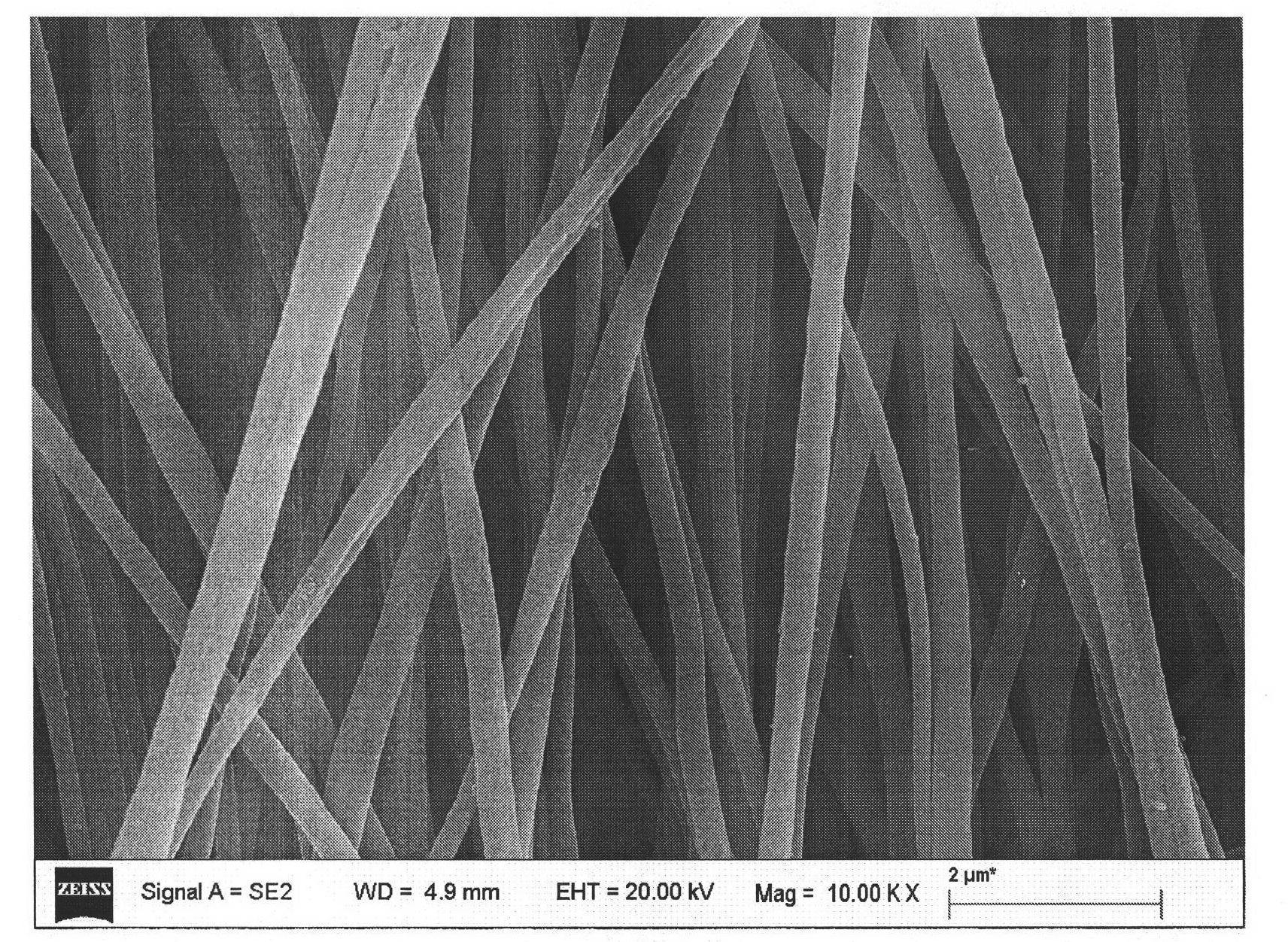

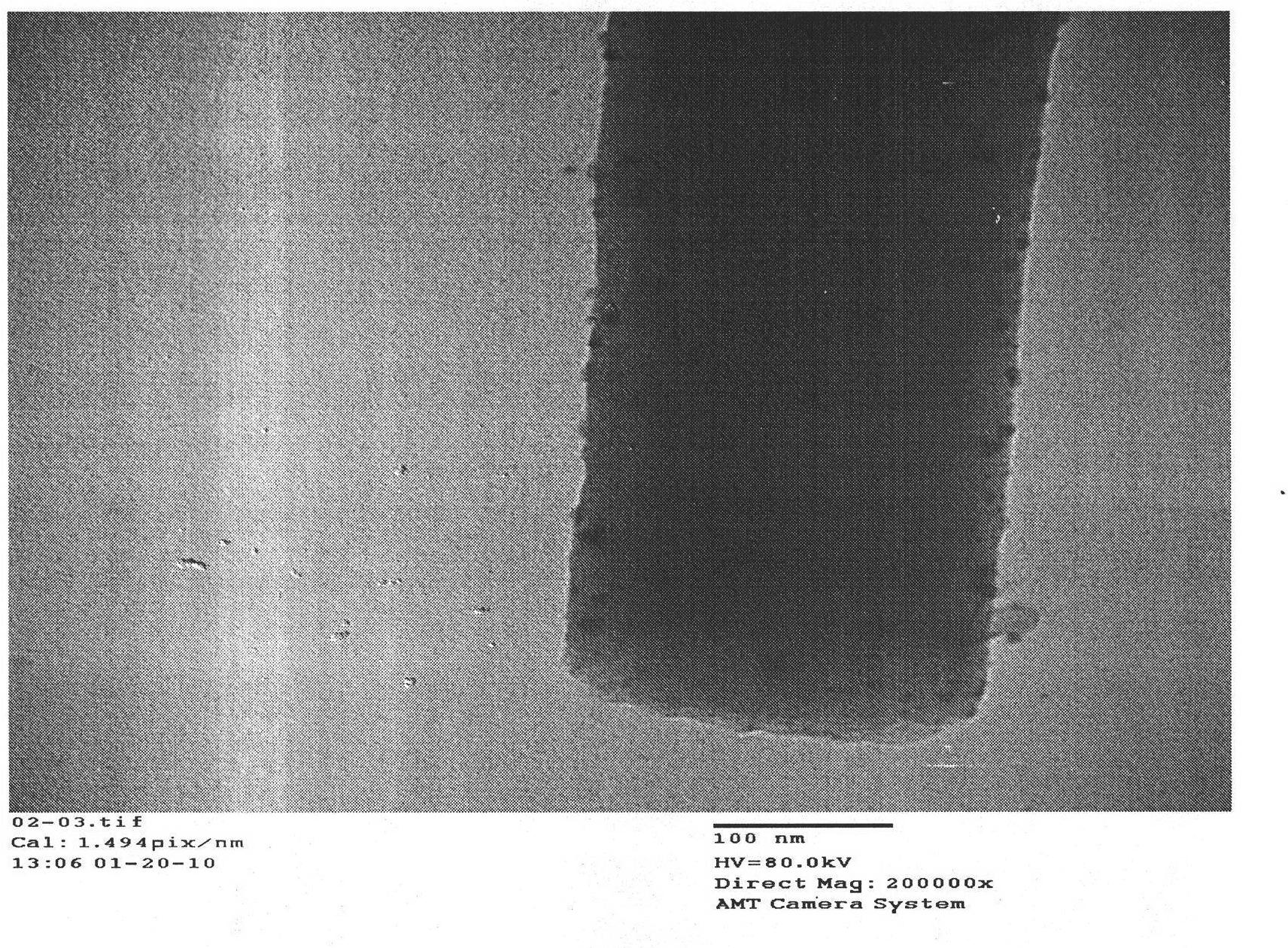

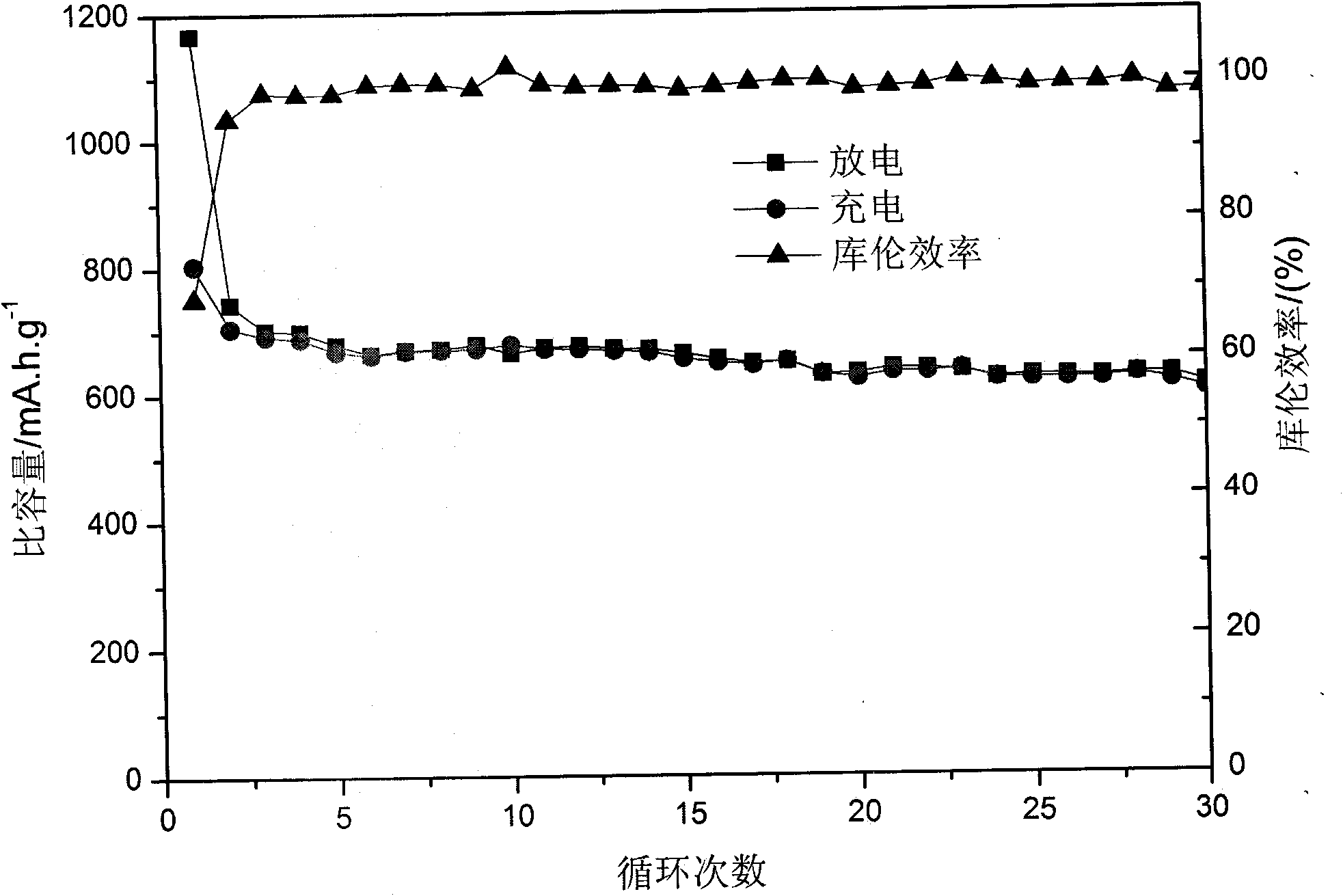

[0031] Dissolve 2g of polyacrylonitrile in a certain amount of nitrogen, nitrogen-dimethylformamide (concentration is 7wt%), drop a certain amount of anhydrous tin tetrachloride into 10ml ethanol (concentration is 0.4mol / L), and ultrasonically stir 24 hours; Take 1ml of ethanol solution dissolved with anhydrous tin tetrachloride and drop it into the nitrogen dissolved in polyacrylonitrile, nitrogen-dimethylformamide, and ultrasonically stir for 12 hours; use the obtained liquid to carry out electrospinning, electrostatic spinning In the spinning process, a No. 12 injection needle (1.1 mm in inner diameter) was selected, the applied electrostatic voltage was 9 kV, the flow rate of the spinning solution was 0.2 mL / h, the receiving distance between the metal cylinder and the needle was 30 cm, and the speed of the outer diameter of the cylinder was 8m / s, the nanofiber felt / membrane was obtained after spinning for 6 hours. The obtained electrospun nanofiber mat / membrane was kept at...

Embodiment 2

[0033]Dissolve 2g of polyacrylonitrile in a certain amount of nitrogen, nitrogen-dimethylacetamide (concentration is 12wt%), get a certain amount of crystalline tin tetrachloride and dissolve it in 13ml acetone (concentration is 1mol / L), and process it with ultrasonic stirring for 24 hours Get 1ml of the acetone solution that is dissolved with crystalline tin tetrachloride, drop into the nitrogen that has dissolved polyacrylonitrile, in the nitrogen-dimethylformamide, ultrasonic agitation process 12 hours; Carry out electrospinning with the liquid obtained, electrospinning In the spinning process, a No. 16 injection needle (inner diameter of 1.6mm) was selected, the applied electrostatic voltage was 15kV, the flow rate of spinning solution was 0.5mL / h, the receiving distance between the metal cylinder and the needle was 25cm, and the speed of the outer diameter of the cylinder was 4m. / s, the nanofiber mat / membrane was obtained after 6 hours of spinning. The obtained electrosp...

Embodiment 3

[0035] Dissolve 2g of polyvinylpyrrolidone in a certain amount of nitrogen, nitrogen-dimethylacetamide (concentration is 15wt%), take a certain amount of tetrabutyltin dropwise into 10ml of anhydrous acetic acid (concentration is 1.6mol / L), ultrasonic stirring treatment for 24 hours Get 1ml of anhydrous acetic acid solution that is dissolved with tetrabutyltin, drop into the nitrogen that has dissolved polyvinylpyrrolidone, in the nitrogen-dimethylformamide, ultrasonic agitation process 12 hours; Carry out electrospinning with the liquid that obtains, electrospinning In the process, a No. 20 injection needle (with an inner diameter of 2.0mm) was selected, the applied electrostatic voltage was 16kV, the flow rate of the spinning solution was 1.0mL / h, the receiving distance between the metal cylinder and the needle was 20cm, and the speed of the outer diameter of the cylinder was 4m / h. s, Nanofiber mat / membrane obtained after 6 hours of spinning. The obtained electrospun nanofib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com