Anti-failure structure for cast iron air preheater and key process thereof

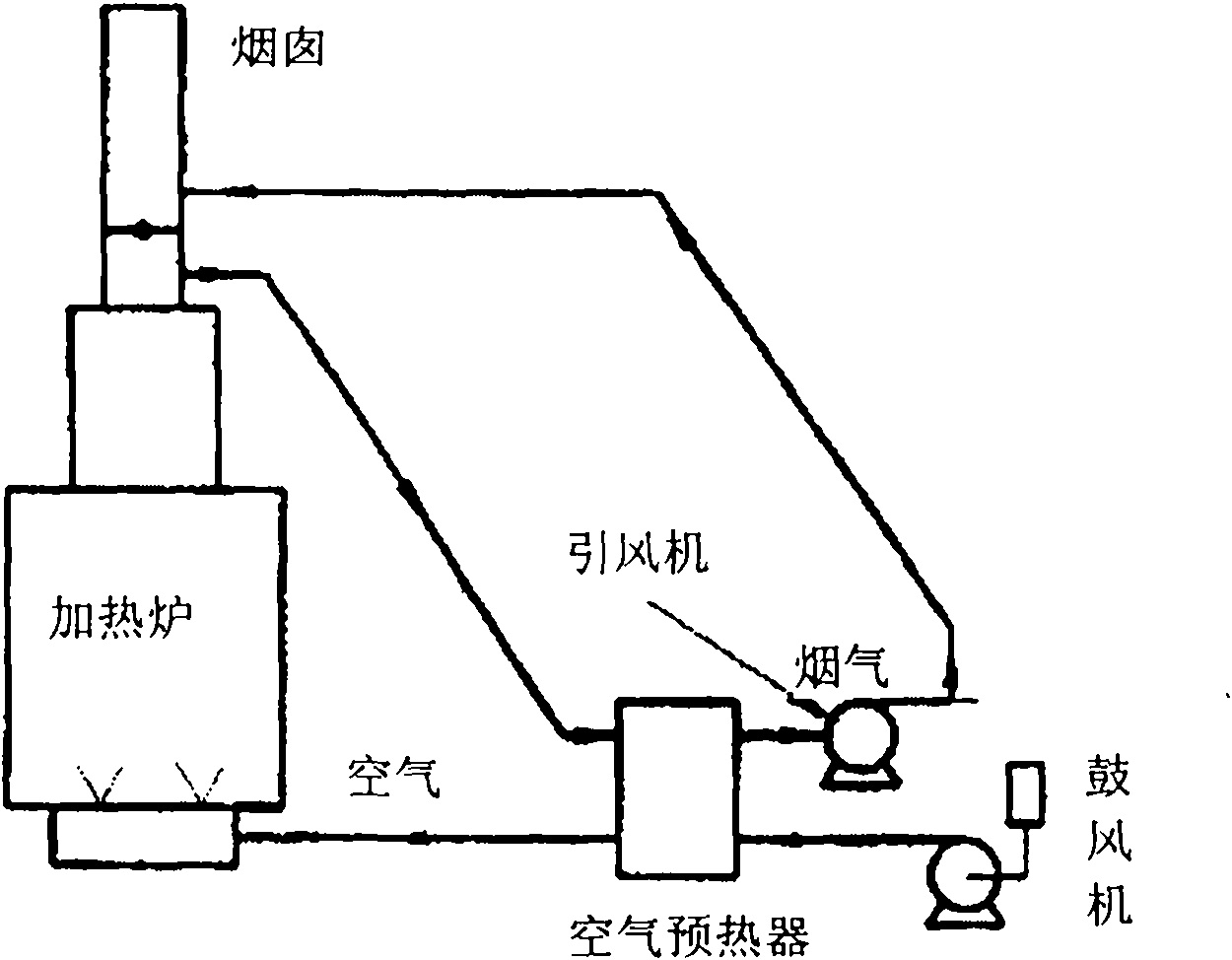

An air preheater, anti-failure technology, used in damage protection, heat transfer modification, heat exchange equipment, etc., can solve problems such as dew point corrosion, reduced thermal efficiency of heating furnace, low temperature, etc., to extend service life and reduce maintenance. effect on maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

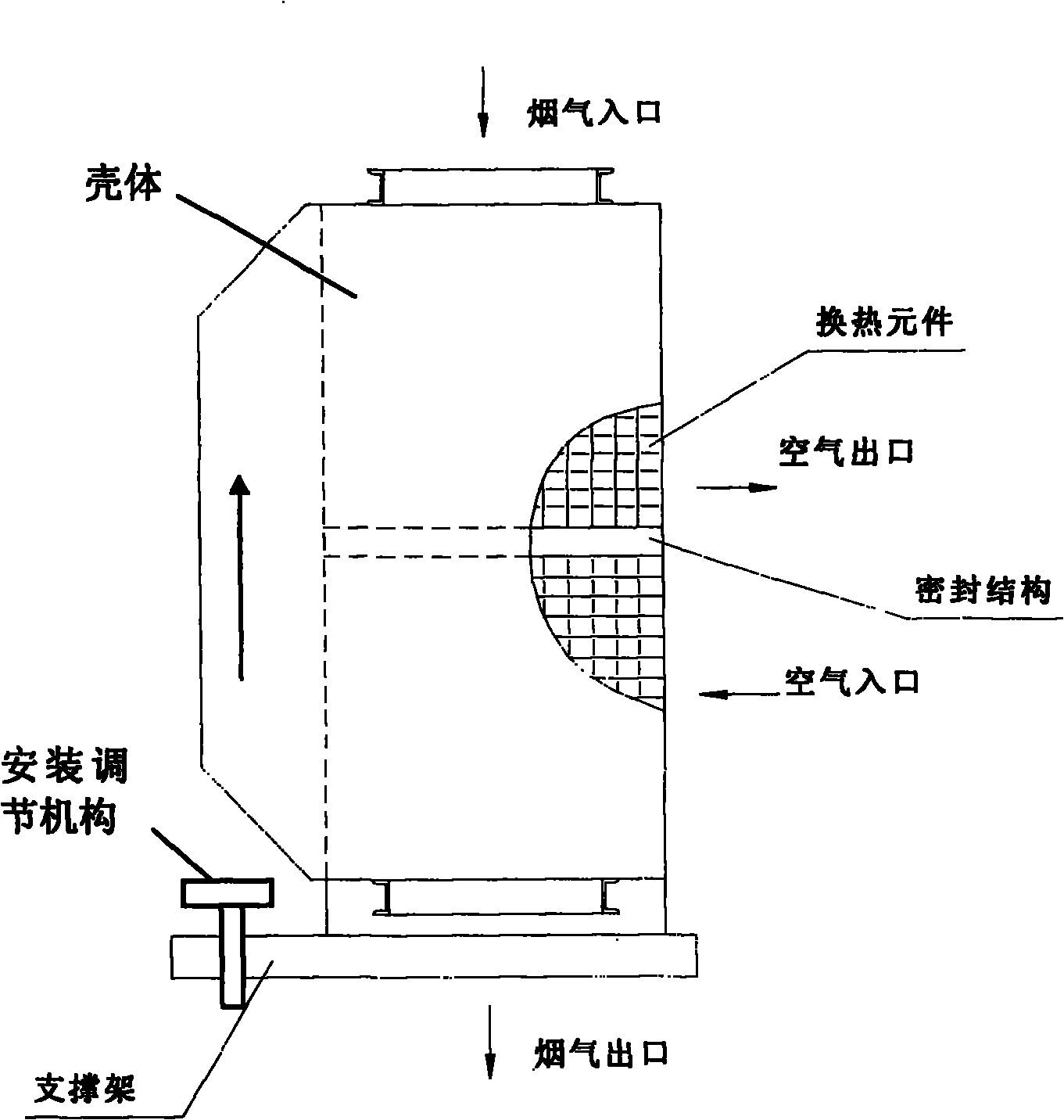

Method used

Image

Examples

Embodiment 1

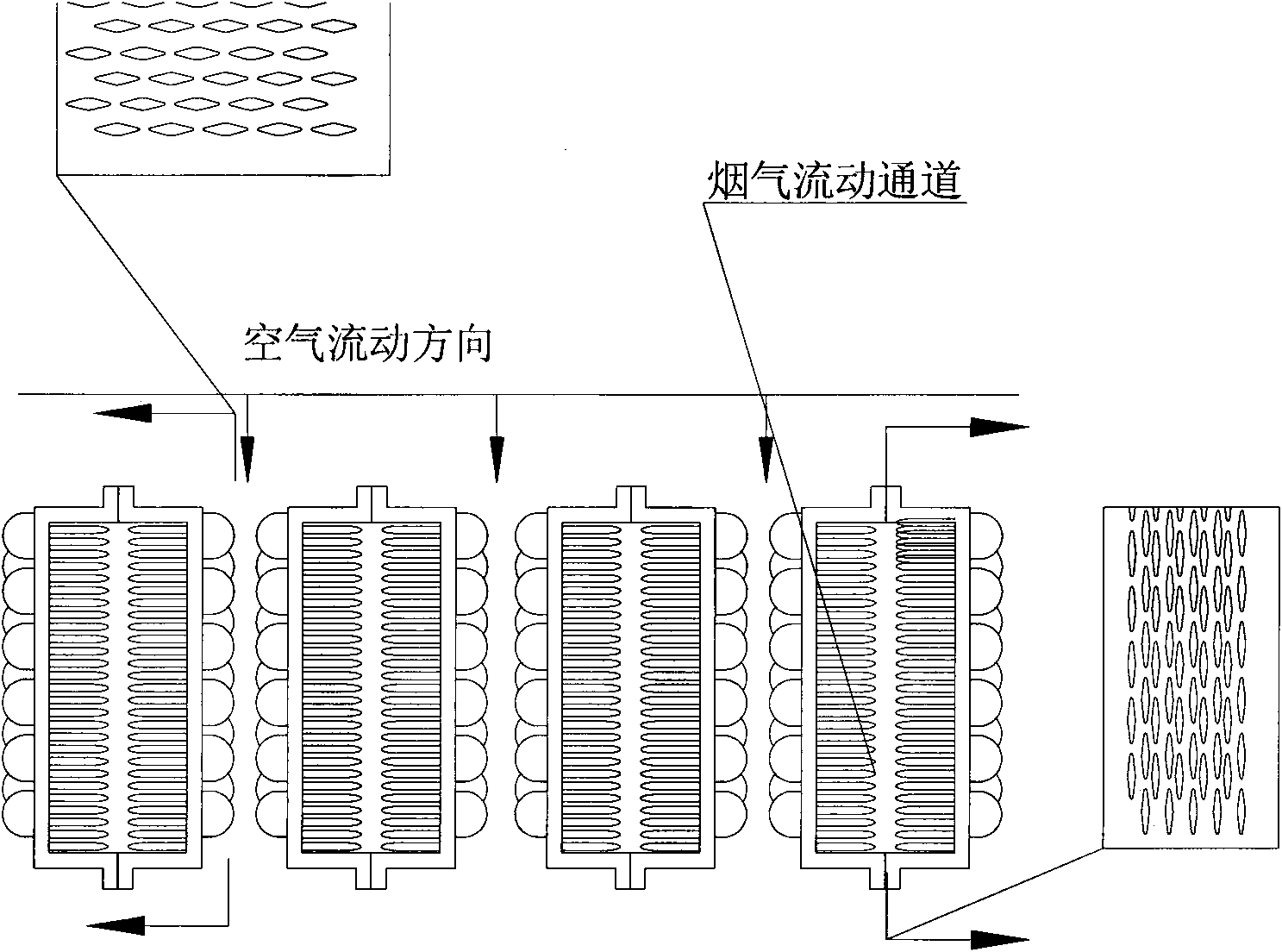

[0051] Firstly, a single piece of cast iron finned plate is manufactured according to the traditional production method, paying attention to ensure the radius of each turning fillet.

[0052] Secondly, an annealing heat treatment is performed on the single cast iron fin plate to eliminate the residual stress inside it caused by uneven casting cold.

[0053] Third, the surface of a single cast iron finned plate is shot blasted and compacted to increase the surface hardness and resist erosion and abrasion. Pay attention to controlling the spray pressure to avoid damaging or breaking the fins.

[0054] Fourth, finish the sealing surface of the single cast iron fin plate to improve the matching accuracy and prevent leakage.

[0055] Fifth, assemble a pair of cast iron finned plates, conduct a body penetration test on a specially set tooling, conduct an airtight test on the sealing surface, conduct a normal temperature static pressure test after passing the test, and finally condu...

Embodiment 2

[0061] In this embodiment, except the following technical features, other parts are the same as in Embodiment 1: in the eighth step of Embodiment 1, "filling metal fiber chips" is changed to "assembling sponge metal fiber clusters", that is, iron filings are compressed and compacted into block before use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com