Method for preparing magnesium alloy

A magnesium alloy and hot extrusion technology, which is applied in the field of metal materials, can solve the problems of low increase range, low increase range of alloy yield strength, and reduced number of metastable phases, so as to achieve the effect of increasing the number, increasing the strength, and improving the strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a magnesium alloy, comprising:

[0026] Solid solution process: heating the as-cast magnesium alloy to 350°C-550°C and performing heat preservation treatment, the as-cast magnesium alloy has the following atomic ratio composition: Mg 1-a-b RE a Zr b , wherein, RE is one or more of Y, Sc, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, 1%≤a ≤6%, 0.05%≤b≤0.5%;

[0027] Hot extrusion process: hot-extruding the magnesium alloy after heat preservation treatment at 350°C-550°C, and then rapidly cooling to room temperature;

[0028] Cold rolling process: cold rolling the hot-extruded magnesium alloy at a reduction of 5% to 50%;

[0029] Aging process: performing aging treatment on the cold-rolled magnesium alloy.

[0030] The present invention uses cast magnesium alloys containing rare earth and zirconium as raw materials to obtain magnesium alloys with high yield strength through solid solution, hot extrusion, ...

Embodiment 1

[0048] Put 85.5g magnesium ingot in SF 6 and CO 2 Melt under the protection of the formed mixed gas, add 14g gadolinium ingot and 0.5g zirconium ingot to the molten magnesium at 700°C, remove the surface residue after melting, and cast after obtaining the melt to obtain cast magnesium alloy, atomic ratio composition As follows: Mg 97.39 Gd 2.46 Zr 0.15 .

Embodiment 2

[0050] The as-cast magnesium alloy prepared in Example 1 was directly extruded with a plate at 505° C. after solid solution for 24 hours at 505° C., the extrusion rate was 0.6 mm / min, and the extrusion ratio was 28: 1; the extruded The alloy is water-quenched immediately; the water-quenched alloy is rolled in one pass at room temperature, and the reduction is 10%; the cold-rolled alloy is aged at 200°C to obtain the peak hardness of aging. magnesium alloy.

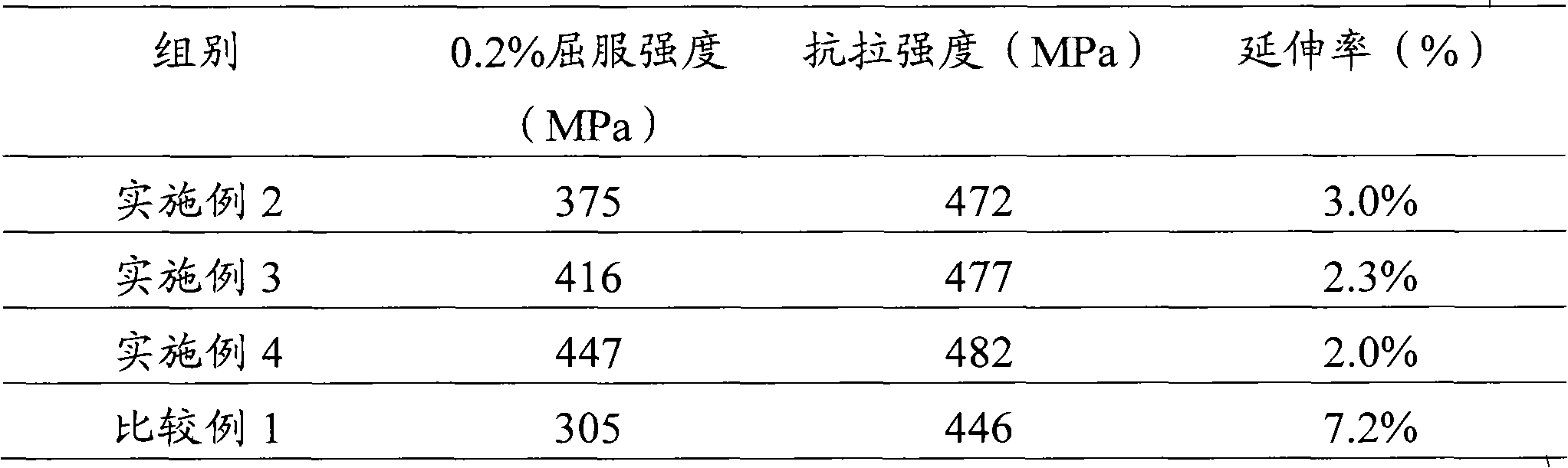

[0051] A tensile test was performed on the magnesium alloy, and the results are shown in Table 1. Table 1 shows the mechanical property test results of the magnesium alloys provided in the examples and comparative examples of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com