Production method of high-light-fastness rutile type titanium dioxide

A technology of rutile titanium dioxide and production methods, which is applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of insufficient light resistance, little contribution, yellowish phase of titanium dioxide pink, etc., to achieve Effects of improving light resistance, improving dispersibility, and high hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

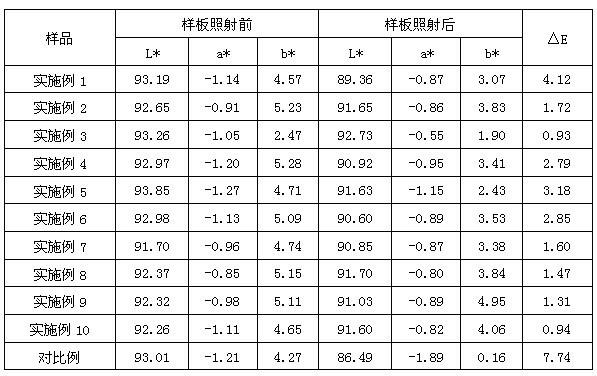

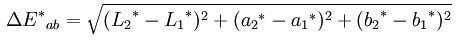

Examples

Embodiment 1

[0035] The preparation method of the high lightfastness titanium dioxide of the present embodiment comprises the following main steps:

[0036] (1) Prepare the slurry containing the primary product of titanium dioxide: weigh 6000g of deionized water, add 12g of SiO 2 Sodium silicate solution, add 6000g uncoated rutile titanium dioxide under stirring to make a concentration of about 800gTiO 2 / L of titanium dioxide slurry, and then sanded with a sand mill to make the titanium dioxide reach the original particle size;

[0037] (2) Use deionized water to dilute the concentration of the qualified titanium dioxide slurry to 300gTiO 2 / L, and then transferred to the coating tank, and the temperature of the slurry was raised to 50°C by indirect steam heating;

[0038] (3), add 150mL40gP 2 o 5 / L (after adding P 2 o 5 with TiO 2 The mass percentage is about 0.1%) of sodium hexametaphosphate solution; then the pH value of the slurry is adjusted to 8.0 with a mass percentage conc...

Embodiment 2

[0044] The preparation method of the high lightfastness titanium dioxide of the present embodiment comprises the following main steps:

[0045] (1) Prepare the slurry containing the primary product of titanium dioxide: weigh 6000g of deionized water, add 12g of SiO 2 Sodium silicate solution, add 6000g uncoated rutile titanium dioxide under stirring to make a concentration of about 800gTiO 2 / L of titanium dioxide slurry, and then sanded with a sand mill to make the titanium dioxide reach the original particle size;

[0046] (2) Use deionized water to dilute the concentration of the qualified titanium dioxide slurry to 200gTiO 2 / L, and then transferred to the coating tank, and the temperature of the slurry was raised to 40°C by indirect steam heating;

[0047] (3), add 1200mL40gP 2 o 5 / L (after adding P 2 o 5 with TiO 2 The mass percent is about 0.8%) of sodium hexametaphosphate solution; then the pH value of the slurry is adjusted to 7.0 with a mass percent concentra...

Embodiment 3

[0053] The preparation method of the high lightfastness titanium dioxide of the present embodiment comprises the following main steps:

[0054] (1) Prepare the slurry containing the primary product of titanium dioxide: weigh 6000g of deionized water, add 12g of SiO 2 Sodium silicate solution, add 6000g uncoated rutile titanium dioxide under stirring to make a concentration of about 800gTiO 2 / L of titanium dioxide slurry, and then sanded with a sand mill to make the titanium dioxide reach the original particle size;

[0055] (2) Use deionized water to dilute the concentration of the qualified titanium dioxide slurry to 400gTiO 2 / L, and then transferred to the coating tank, and the temperature of the slurry was raised to 70°C by indirect steam heating;

[0056] (3), add 3000mL30gP 2 o 5 / L (after adding P 2 o 5 with TiO 2The mass percent is about 1.5%) phosphoric acid solution; then the pH value of the slurry is adjusted to 7.5 with a mass percent concentration of 15% d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com