Novel micro/nano trivalent silver iron compound synthesizing method

A trivalent silver ion, micro-nano technology, applied in silver compounds, silver compounds, chemical instruments and methods, etc., can solve the problems of large water consumption, difficult to uniformly control product particle size, high energy consumption, and achieve good exchange and avoidance. The effect of mass generation and uniform distribution of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

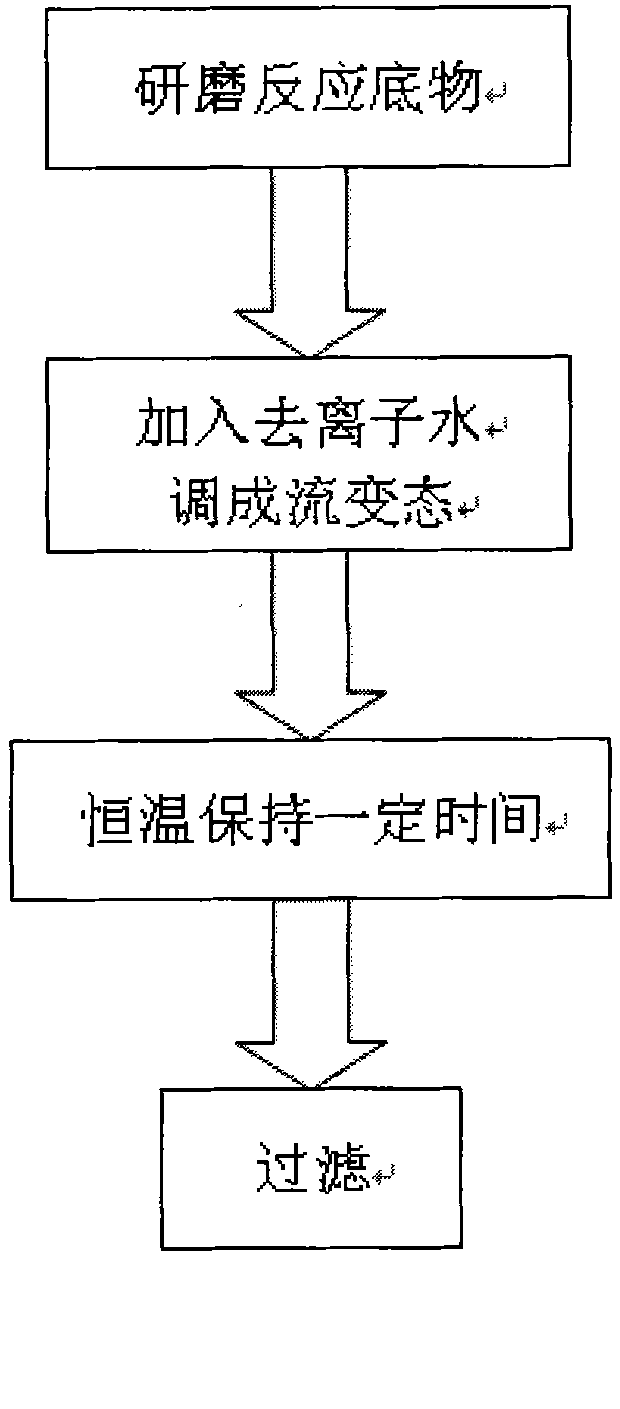

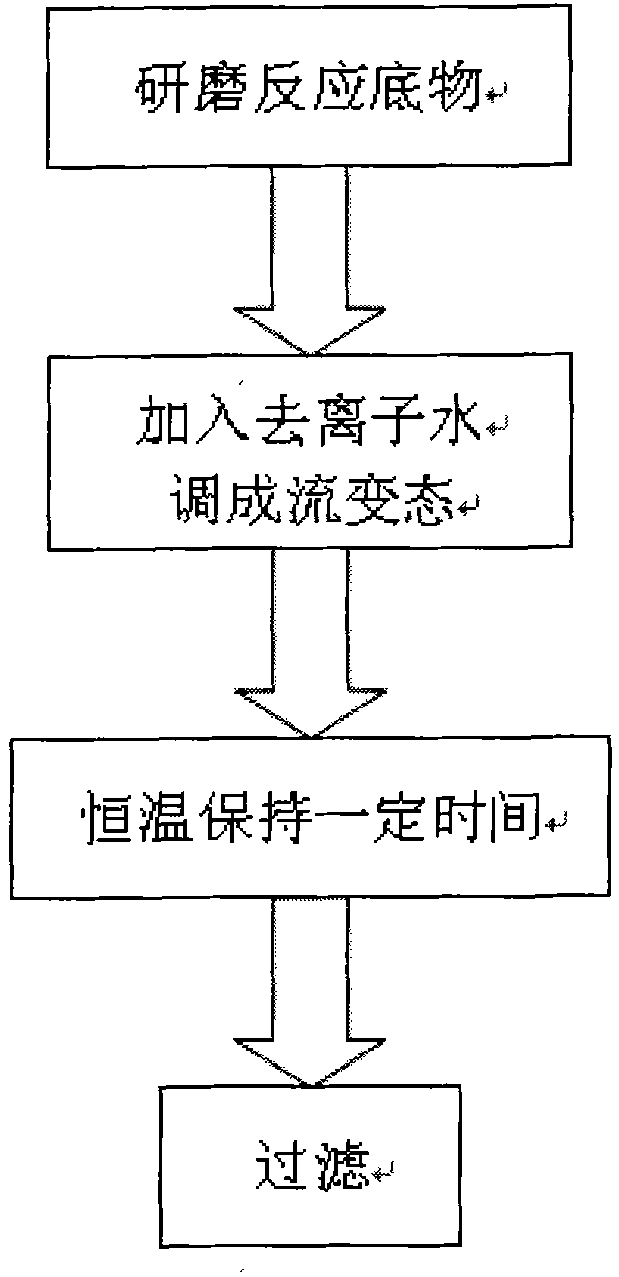

[0017] like figure 1 Weigh the reaction substrate according to the following proportions: 0.1-0.3 parts of sodium hydroxide or potassium hydroxide, 1.0-2 parts of tetrasilver tetroxide, 1-3 parts of sodium persulfate or potassium persulfate, fully grind and mix evenly, each Add 3 to 5 parts of deionized water to 10 parts of the reaction substrate, adjust it into a rheological state, keep it at 50 to 80°C for 1 to 2 hours, filter, and rinse with pure water four times to wash away unreacted potassium persulfate or persulfuric acid Sodium and potassium hydroxide or sodium hydroxide and other impurities to obtain micronano trivalent silver ion compounds.

[0018] Below in conjunction with specific embodiment, further illustrate the present invention.

[0019] Weigh 6g of sodium persulfate, 0.6g of sodium hydroxide and 4g of tetrasilver tetroxide, put them into a mortar, grind them evenly, add 3.5ml of deionized water, keep warm at 80°C for 1h, filter, and rinse with pure water fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com