Method for preparing high-concentration silica sol by using superfine silica powder

A technology of silicon dioxide and ultrafine silicon powder, applied in the direction of silicon dioxide and silicon oxide, can solve the problems of unsuitable uniformity, no recycling method, waste, etc., achieve easy operation, avoid hindering sol generation, and be practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

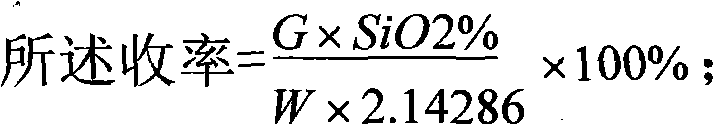

Image

Examples

Embodiment 1

[0030] A method for preparing high-concentration silica sol from ultrafine silica powder, comprising the following steps:

[0031] Add 20g of elemental silicon powder with a particle size of about 1340 mesh and 150ml of deionized water into a three-necked flask, heat to 60°C, and preheat for 20 minutes to activate the silicon powder. Take 8g of water glass and 20ml of 10% ammonia solution, add water to dilute to 50ml, and stir evenly. Place the three-necked flask in a constant temperature water bath at 90°C, quickly add half the volume of the prepared mixed solution, stir the three-necked flask with an electric stirrer, and monitor the pH value change in the three-necked flask with an acidity meter. The pH value in the bottle is 9.7, and the pH value is measured every 10 minutes. The pH value drops rapidly at the beginning, and tends to be stable when the pH value drops to 8.6. At this time, the remaining 1 / 2 volume of the mixed solution is added dropwise. The dropwise additi...

Embodiment 2

[0033]Add 25g of elemental silicon powder with a particle size of about 2000 mesh and 150ml of deionized water into a three-neck flask, heat to 50°C, and preheat for 20 minutes to activate the silicon powder. Weigh 0.32g of sodium hydroxide, add 100ml of deionized water to prepare a sodium hydroxide solution, and stir evenly. Place the three-necked flask in a constant temperature water bath at 90°C, quickly add half the volume of the prepared sodium hydroxide solution, stir the three-necked flask with an electric stirrer, and monitor the pH change in the three-necked flask with a pH meter. At this time, the pH value in the bottle is 10.5, and the pH value is measured every 10 minutes. The pH value drops rapidly at first, and tends to be stable when the pH value drops to 9.1. 10.0, considering that part of the water evaporates as the reaction proceeds, the pH value will increase. In order to avoid the pH value exceeding 10.0, an appropriate amount of deionized water is added at...

Embodiment 3

[0035] Add 20g of elemental silicon powder with a particle size of about 2000 mesh and 150ml of deionized water into a three-neck flask, heat to 50°C, and preheat for 10 minutes to activate the silicon powder. Weigh 0.24g of sodium hydroxide, add 50ml of deionized water to prepare a sodium hydroxide solution, and stir evenly. Place the three-necked flask in a constant temperature water bath at 90°C, quickly add 25ml of the prepared sodium hydroxide solution, stir the three-necked flask with an electric stirrer, and monitor the pH value change in the three-necked flask with a pH meter. The pH value is 9.3, and the pH value is measured once every 10 minutes. At the beginning, the pH value drops rapidly, and tends to be stable when the pH value drops to 8.8. At this time, the remaining 25ml sodium hydroxide solution is added dropwise. Completed within 0.5 hours. Continue to adjust and control the pH between 8.5-10.0. The whole reaction time is 8 hours, and the whole process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com