Liquid-state silicon gel injection forming machine

An injection molding machine and liquid silicone technology, which is applied in the field of liquid silicone injection vulcanization molding machines, can solve problems such as the difficulty in controlling the amount of color paste added accurately, the difference in product appearance and color, and the impact on product quality, and achieve superior performance and good sealing. , the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

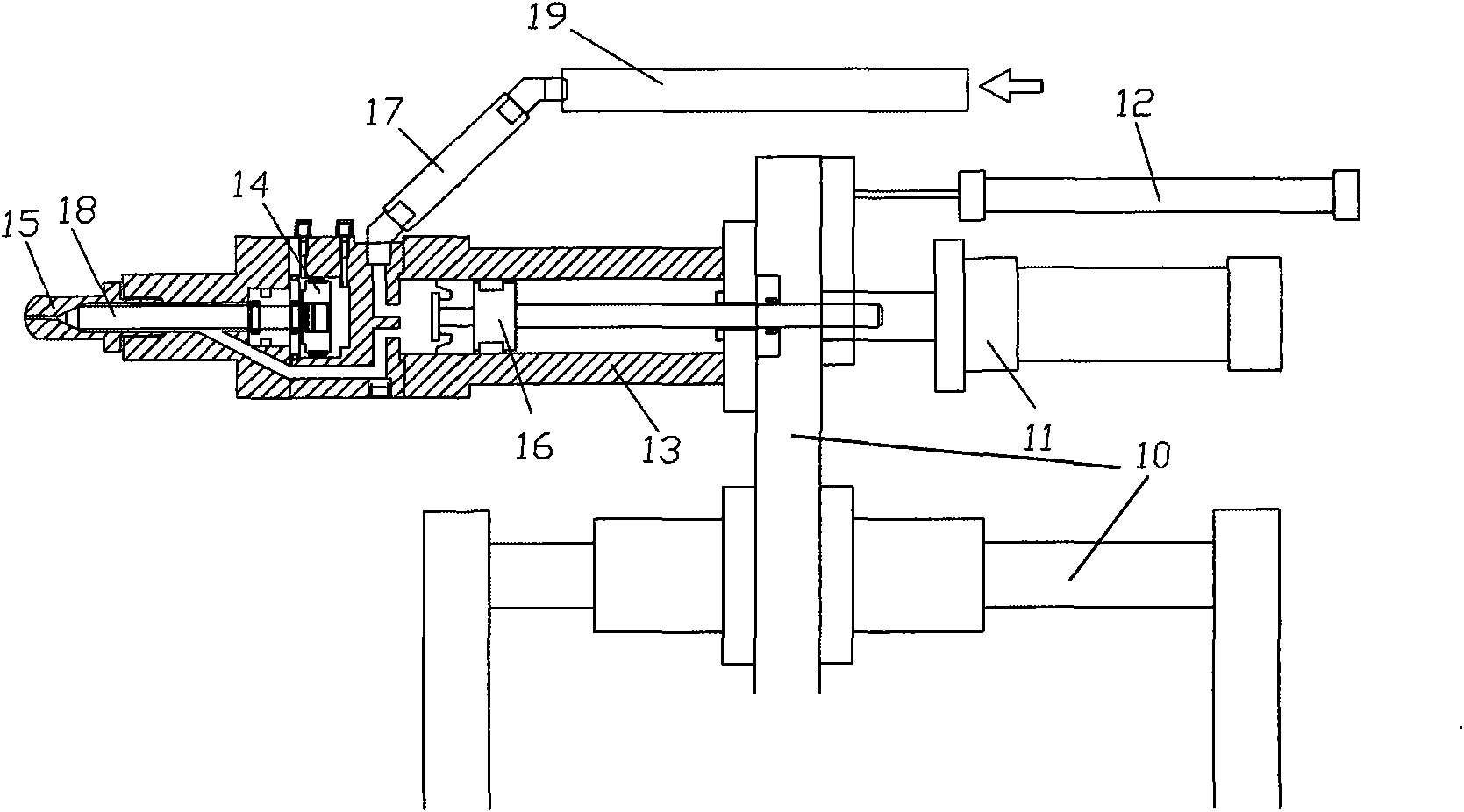

[0023] see figure 1 , the direct pressure injection barrel includes an injection cylinder 11, which is fixed on the machine base 10 by four pillars, an electronic ruler 12 is fixed on the flange plate of the injection cylinder 11, and the movable part of the electronic ruler 12 is fixed on the bottom of the injection cylinder 11. The top of the movable rod moves with the injection cylinder 11 at the same time, so that the amount of feeding and the injection volume can be measured each time. The material holding barrel 13 is fixed on the machine base 10 by screws, and is coaxial with the injection cylinder 11. The barrel 13 is equipped with an injection piston rod 16, and the top of the injection piston rod 16 is equipped with seals and wear-resistant parts so that the injection piston rod 16 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com