Nitrous oxide fuel blend monopropellants

A technology of nitrous oxide and propellants, applied in the direction of fuel, gas fuel, liquid carbon-containing fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The mixing of fuel and oxidizer must be done in a controlled, measured manner to ensure that the resulting unit propellant has the desired performance characteristics.

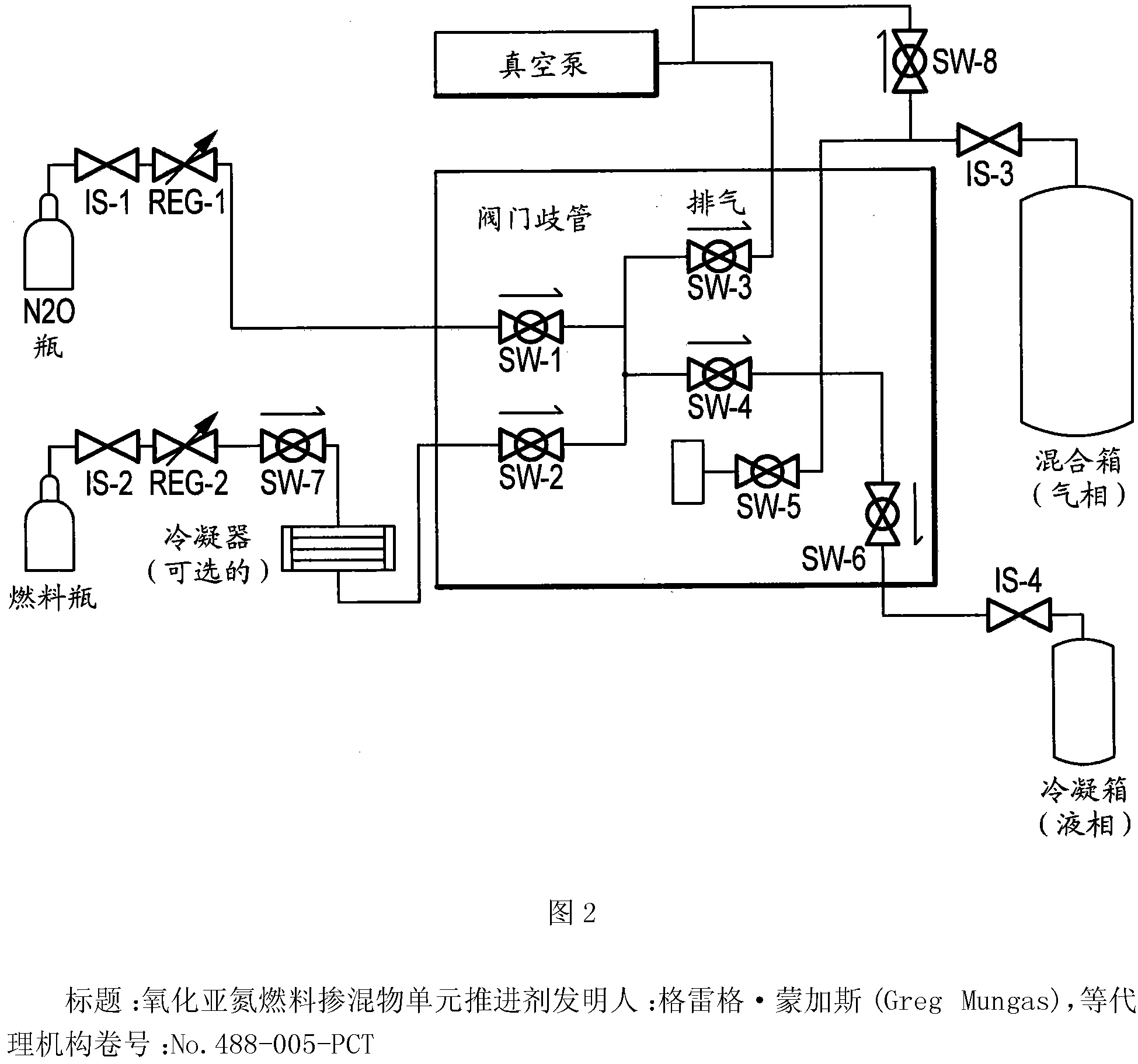

[0041] figure 2 An exemplary schematic diagram of an apparatus for producing a NOFB unit propellant blend is illustrated. Propeller performance depends on the propellant burned. For this reason, it is often important to precisely mix unit propellant blends. A special device can be used to mix high vapor pressure unit propellants. In fact, these components can be mixed in their vapor phases and condensed in separate vessels to form a high-density liquid unit propellant. The methods and apparatus listed below are for illustrative purposes and derivatives thereof are equally acceptable methods of production. In this embodiment, SW-#s designate general on / off valves, REG-#s designate pressure reducing regulators, and IS-#s are tank separation valves. All valves were initially closed with regulators fu...

Embodiment 2

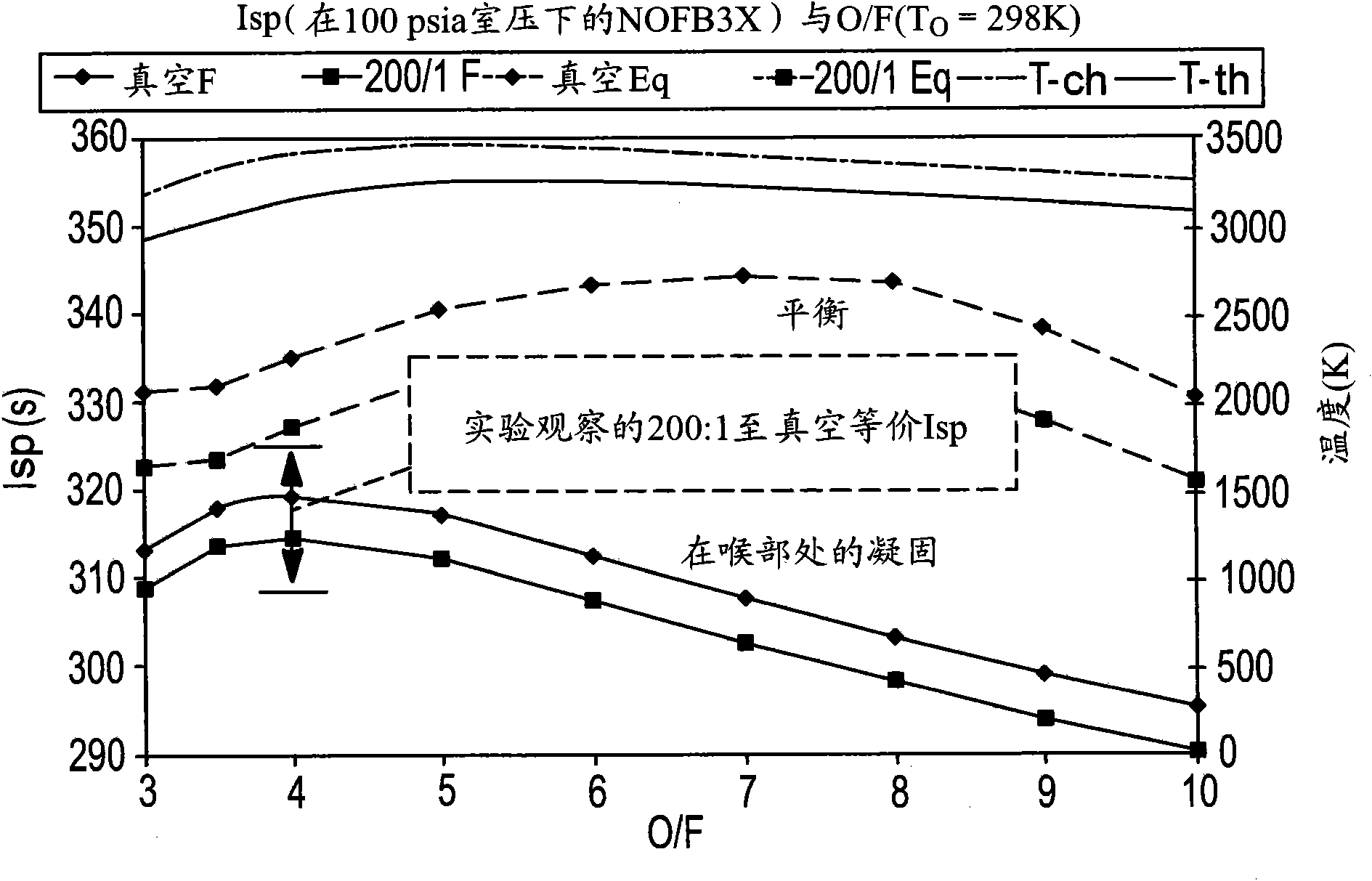

[0043] Produce and test candidate fuel blends. The most promising blends were selected based on the following criteria: combustion and theoretical engine performance; propellant stability; equilibrium and non-equilibrium miscibility properties; burn limit, flame temperature, and exhaust chemistry of the engine design; Graph properties, and combustion reaction rates.

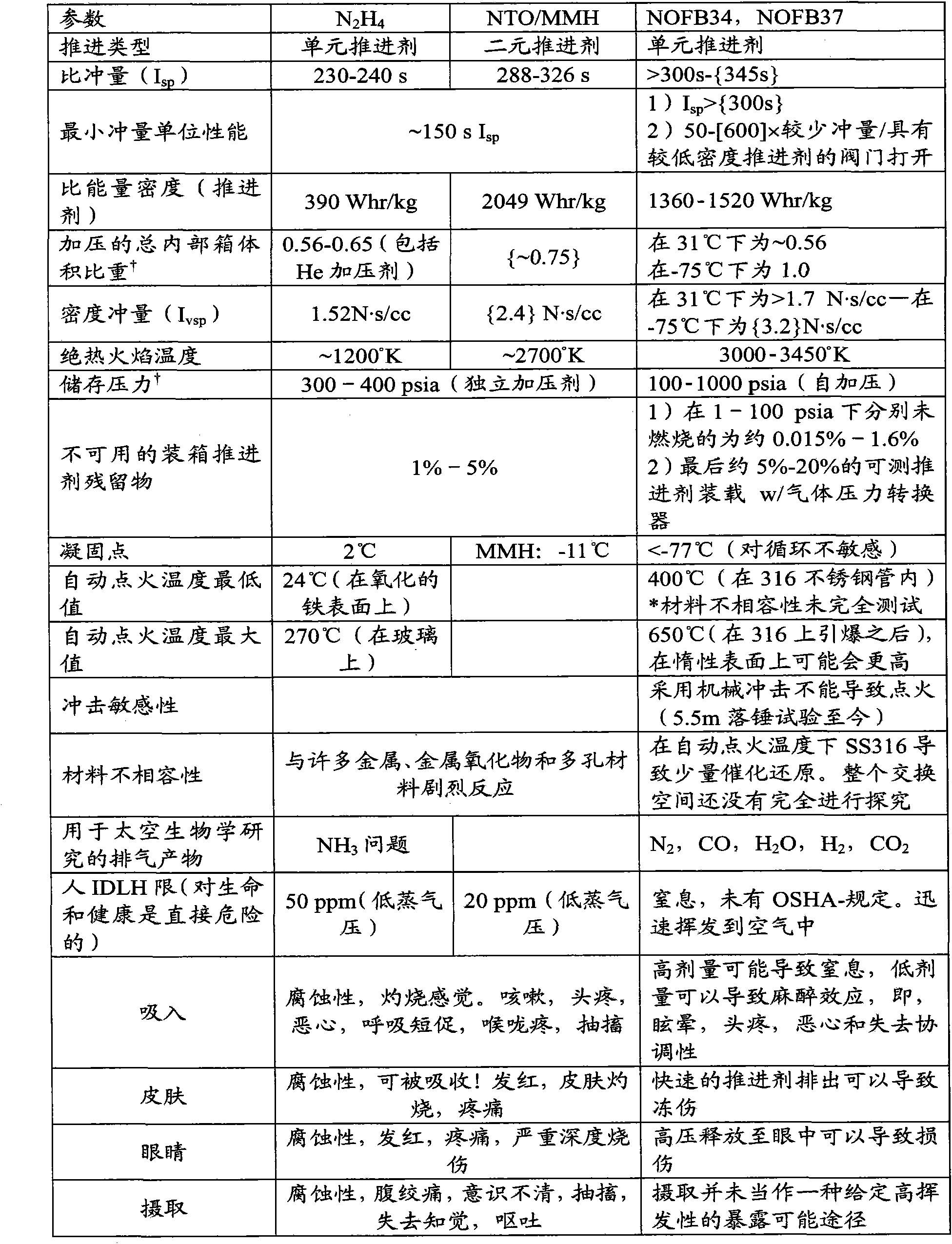

[0044] The unit propellants of the present invention are named in the following manner. "NOFB" stands for Nitrous Oxide Fuel Blend. The next number indicates the position in group C2, 1 being ethane, 2 being ethylene, and 3 being acetylene. The numbers that follow indicate the oxidizer to fuel ratio. Thus, "NOFB34" is nitrous oxide blended with acetylene at an oxidizer-to-fuel ratio of 4. Additional letters (a, b, c) after the oxidizer-to-fuel ratio numbers may be used to describe differences in blends. For example, NOFB34 blends may include small amounts of specific additives to improve the chemical degassi...

Embodiment 3

[0051] Except I spIn addition to performance, many other properties of unit propellants are generally considered desirable. Hydrazine has an OSHA human lethal exposure limit of approximately 50 ppm. Low and non-toxic chemical unit propellant formulations are required to mitigate the relatively high costs of ground handling and work with toxic unit propellant formulations. The NOFB unit propellant formulation of the claimed invention is non-toxic and classified as an asphyxiating agent - in this respect NOFB is similar to gasoline, and only at very high concentrations overexposure will displace breathable air, causing asphyxiation or in more severe In mild cases can cause temporary exposure symptoms such as headache and / or confusion. In any event, removal to supply fresh air will relieve symptoms of exposure. The NOFB unit propellant evaporates rapidly into the air allowing large concentrations of liquid to be easily removed from the splashdown. Also, where hydrazine and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com