Single-phase self-starting permanent magnet synchronous motor

A permanent magnet synchronous motor, self-starting technology, applied to synchronous motors with static armatures and rotating magnets, synchronous machine parts, magnetic circuit static parts, etc., can solve the problem of reluctance torque and electromagnetic torque. Uniformity, reduced starting torque, unstable motor operation, etc., to achieve the effect of improving uniformity, improving magnetic field strength, and increasing magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

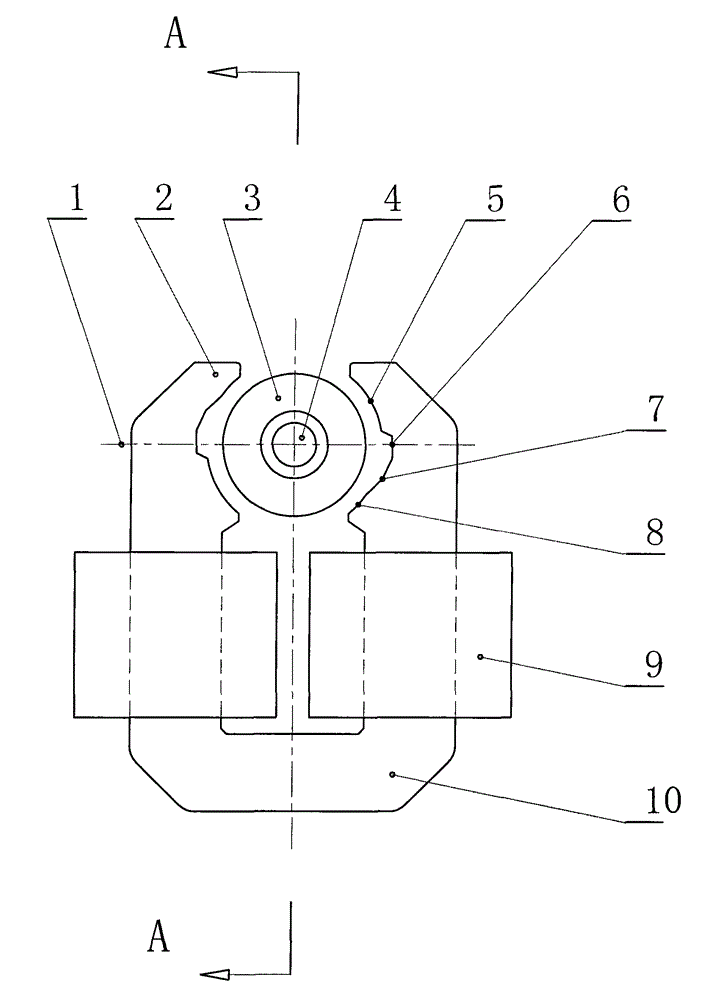

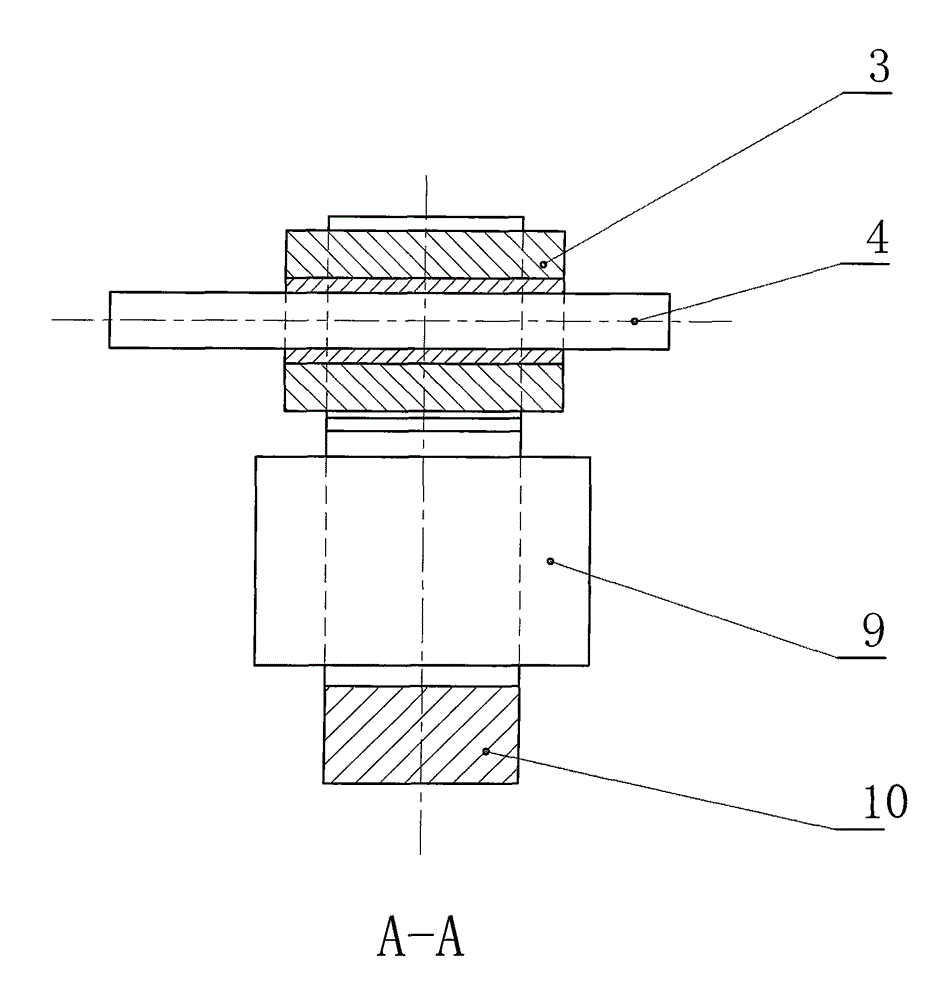

[0046] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0047] Depend on figure 1 , figure 2 Visible, the present invention is made of permanent magnet rotor (3), stator iron core (10) and stator winding (9), and permanent magnet rotor (3) is the cylindrical permanent magnet rotor of radial two-pole magnetization, and permanent magnet rotor (3 ) outside is a stator composed of a stator core (10) and a stator winding (9), the stator core (10) is U-shaped, the stator winding (9) is installed on the stator core (10), and grows out of the stator winding (9) The two ends of the stator core (10) are two opposite stator poles (2), and the inner side of the stator pole (2) is two opposite pole arcs, and the pole arcs on each side are not strictly arc-shaped, so that in the stator Non-uniform air gaps with different air gap lengths are formed on both sides of the pole center line (1), and the pole ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com