Hybrid-power engine with square rotor

A hybrid, square technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of shortening the life of the whole machine, increasing the total time, reducing the fuel power of the engine, etc., to improve the energy conversion efficiency and increase the energy conversion. Efficiency, the effect of improving the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] 1. Various parts of the present invention

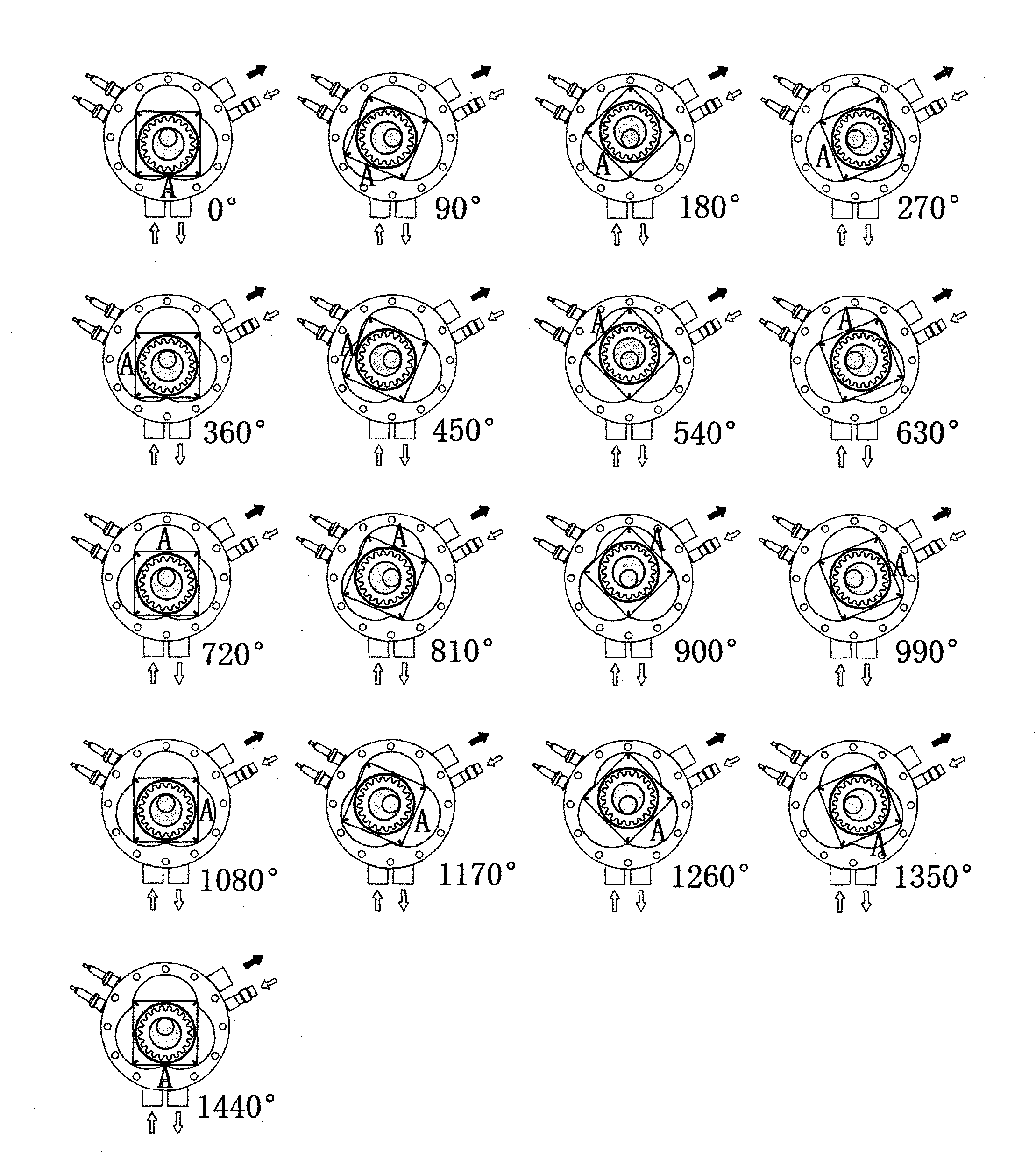

[0028] Such as figure 1 Shown is the schematic diagram of the appearance of the engine. From the figure, it can be understood that the shape of the engine of the present invention is a cylinder, and the output shaft (1) protrudes from the center points of the upper and lower top surfaces of the cylinder to connect the load equipment. The stator of motor is to be arranged side by side by the stator casing (3) that forms cylinder cavity and casing upper and lower cover (16), is fixed by a plurality of casing bolts (21) of a circle and forms. On the circumferential side wall of the cylindrical stator housing (3), there are combustible gas inlets (5), exhaust gas outlets (7), spark plugs (8), water sprayers (9) and water vapor outlets (6), to be used to realize the whole cycle of the present invention.

[0029] Such as figure 2 Shown is the cross-sectional schematic diagram of the present invention, has marked several importan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com