Fermentation production method of validamycin A

A production method, the technology of Jinggangmycin, applied in the field of Jinggangmycin fermentation production, can solve the problems of affecting cost, no improvement in energy saving and production increase of Jinggangmycin, affecting the total output of Jinggangmycin, etc., to achieve increased production rate, high Relative potency, shortening the effect of fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

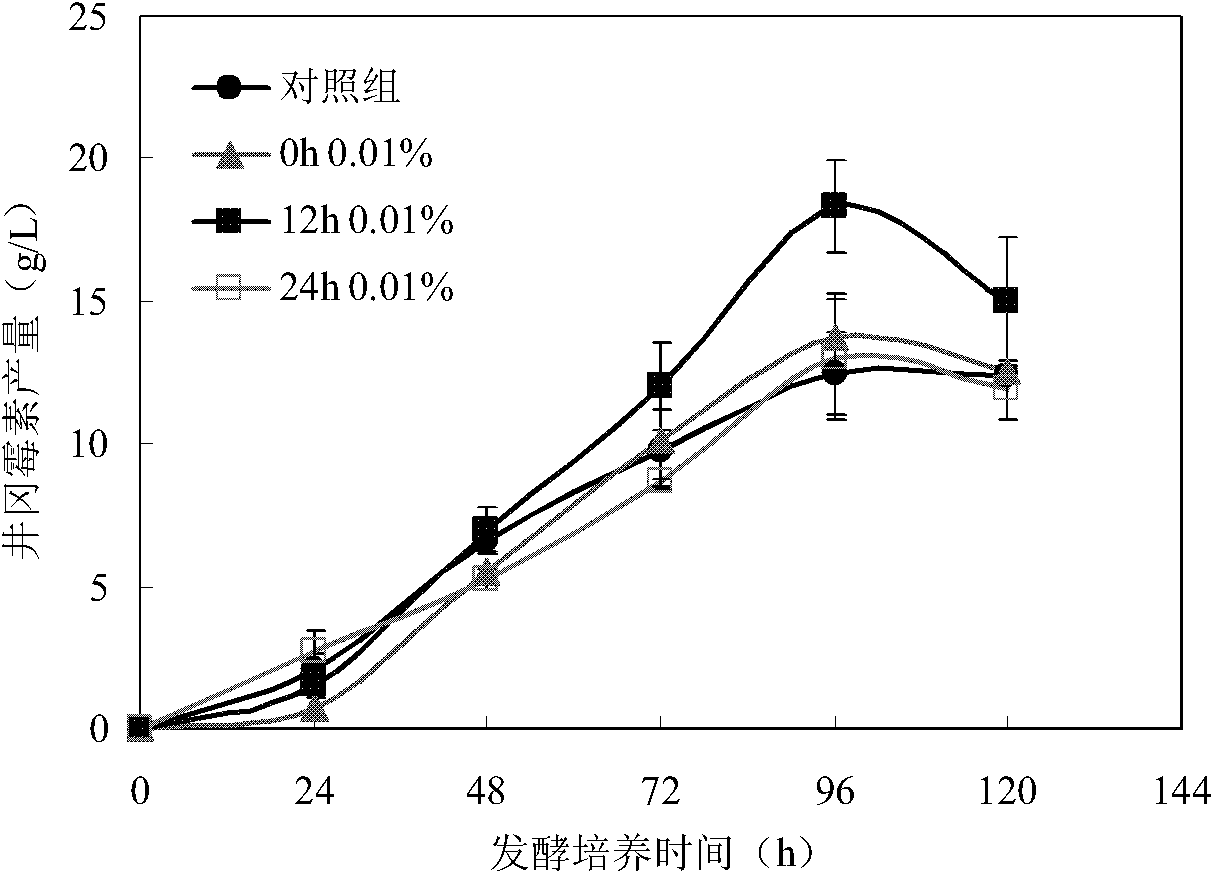

[0024] The effect of ethanol addition time on the yield of Jinggangmycin in the fermentation medium was investigated. Three time periods were selected: 0h before inoculation of the seed solution, 12h after the start of fermentation, and 24h after the start of fermentation. Different concentrations of ethanol were added for fermentation experiments. The implementation steps and results are as follows:

[0025] 1. Implementation steps

[0026] (1) Strain activation and plate culture

[0027] Soybean cake powder, mannitol, and agar are made into a plate medium at a concentration of 2%, and the plate is sterilized and cooled before use. Melt the spore suspension of Jinggangmycin-producing bacteria Streptomyces hygroscopicus 5008 stored at -70°C, spread it on a solid medium plate, then turn the plate upside down, and after culturing at 37°C for 5-8 days, the surface of the plate can be seen Large numbers of cyan spores are formed. Add 5 mL of sterile water to the well-grown plat...

Embodiment 2

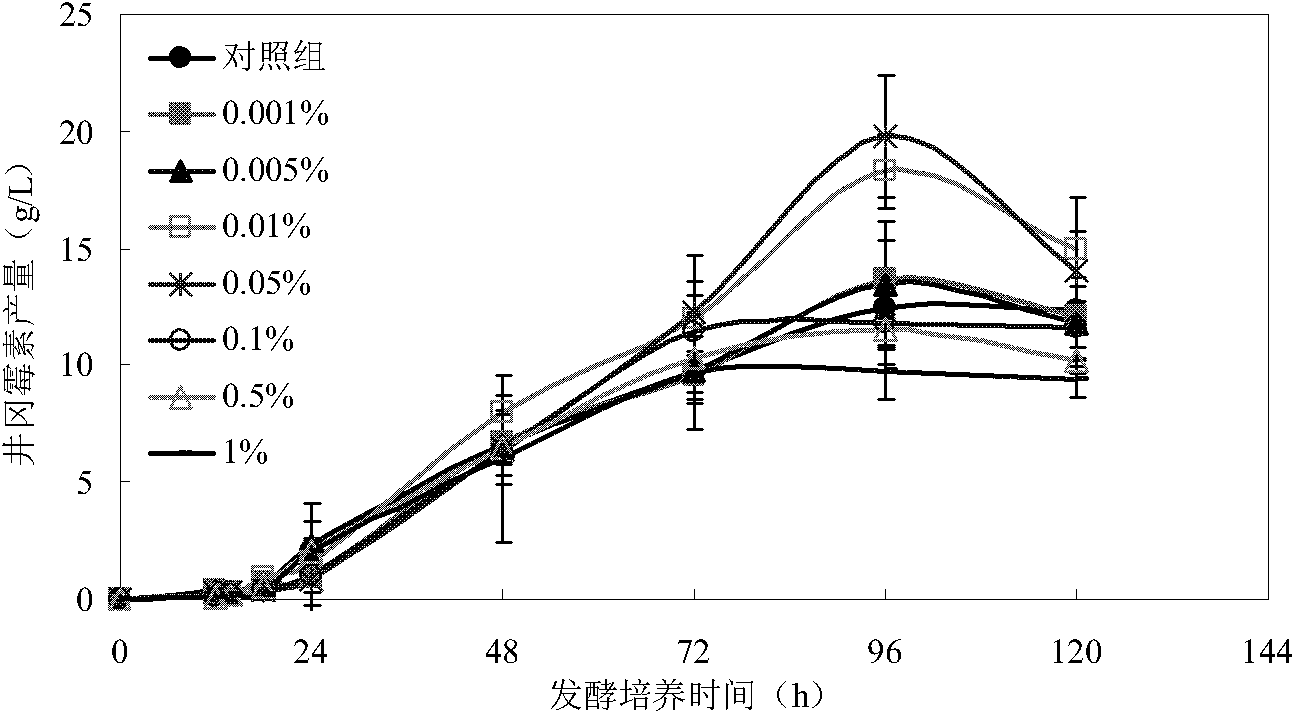

[0038] Adding ethanol to the fermentation medium at 12 hours can increase the yield of Jinggangmycin. Next, the effects of different ethanol additions on the yield of Jinggangmycin were compared in more detail, and four relatively low addition concentrations were selected first: 0.001%, 0.005% , 0.01%, 0.05%. The implementation steps and results are as follows:

[0039] 1. Implementation steps

[0040] (1) Strain activation and plate culture

[0041] Soybean cake powder, mannitol, and agar are made into a plate medium at a concentration of 2%, and the plate is sterilized and cooled before use. Melt the spore suspension of Jinggangmycin-producing bacteria Streptomyces hygroscopicus 5008 stored at -70°C, spread it on a solid medium plate, then turn the plate upside down, and after culturing at 37°C for 5 days, it can be seen that a large amount of of cyan spores. Add 5 mL of sterile water to the well-grown plate of the spores, and gently scrape the spores covered on the surf...

Embodiment 3

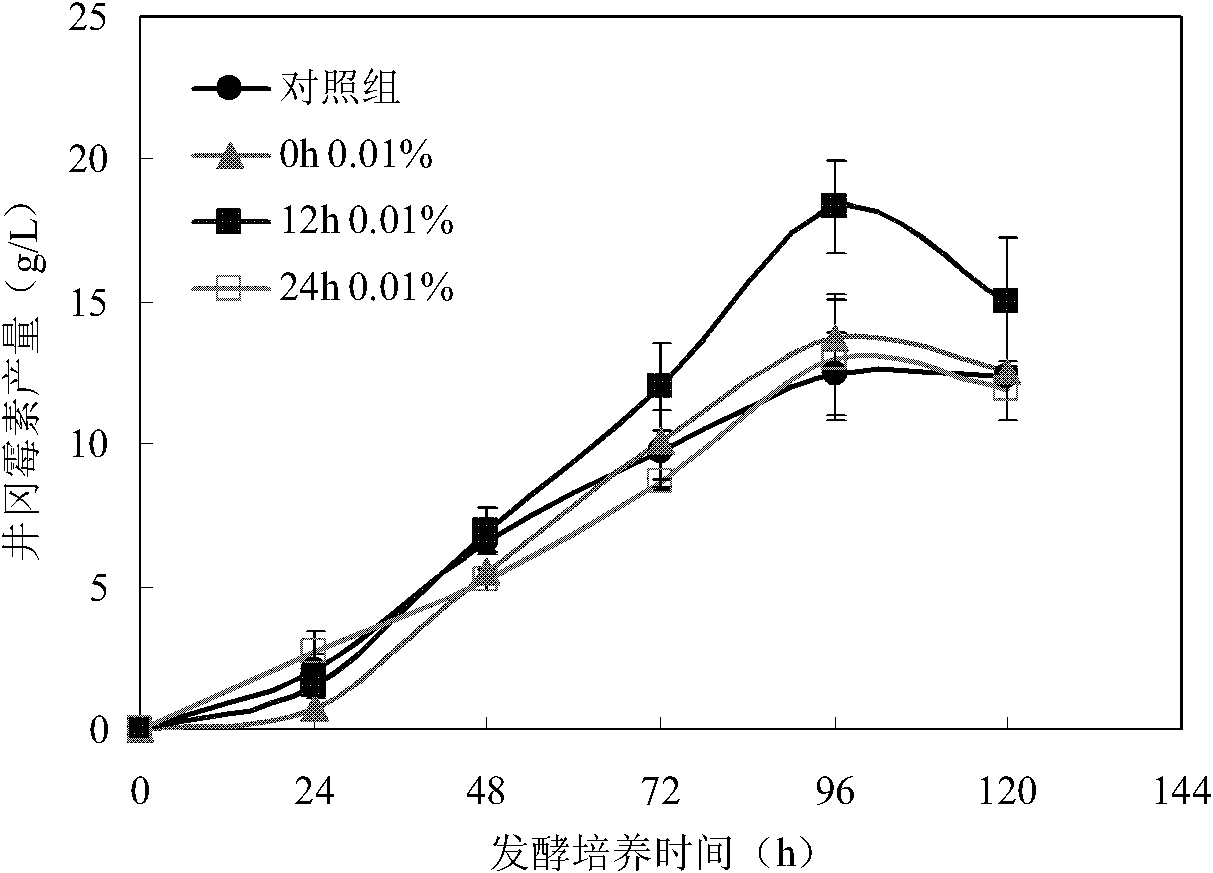

[0057] Adding ethanol to the fermentation medium at 12 hours can increase the yield of Jinggangmycin, and then compared the effects of different ethanol additions on the yield of Jinggangmycin in more detail, and selected three relatively high concentrations: 0.1%, 0.5% ,1%. The implementation steps and results are as follows:

[0058] 1. Implementation steps

[0059] (1) Strain activation and plate culture

[0060] Soybean cake powder, mannitol, and agar are made into a plate medium at a concentration of 2%, and the plate is sterilized and cooled before use. Melt the spore suspension of Jinggangmycin-producing bacteria Streptomyces hygroscopicus 5008 stored at -70°C, spread it on a solid medium plate, then turn the plate upside down, and after culturing at 37°C for 7 days, it can be seen that a large amount of of cyan spores. Add 5 mL of sterile water to the well-grown plate of the spores, and gently scrape the spores covered on the surface of the plate with a coating rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com