Acid rain corrosion resisting concrete additive and preparation method thereof

A technology of concrete and admixtures, which is applied in the field of building materials, can solve problems such as the inability to meet the design requirements for acid rain erosion resistance, and achieve the effects of improving acid rain erosion resistance, reducing intrusion ability, improving strength and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

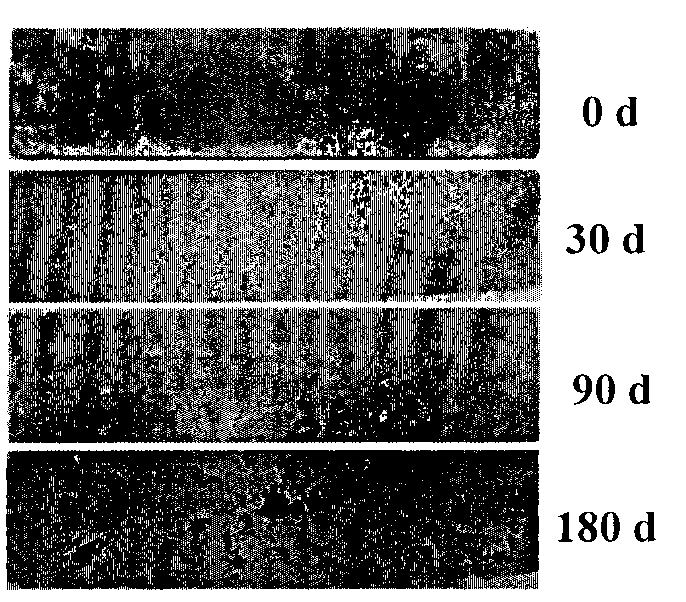

Image

Examples

Embodiment 1-2

[0046] 1, the preparation method of high anti-acid rain erosion concrete admixture, it comprises the steps:

[0047] 1) select raw material and prepare this admixture by the material proportioning shown in table 1

[0048] Raw material ratio in the admixture of table 1

[0049]

Example

Finely ground slag: high calcium fly ash: silica fume

(parts by weight)

organic fiber

functional enhancement components

1

100∶200∶30

3.5%

1.2%

5%

2

100∶225∶20

4%

1.8%

6%

[0050] (Note: The ground slag, high-calcium fly ash and silica fume are selected from mineral materials that meet the above-mentioned respective technical indicators. After drying, the moisture content is 0.5%; the polymer, organic fiber and functional strengthening components The amount added is the mass percentage of the ground slag, high-calcium fly ash and silica fume mass)

[0051] 2) P...

Embodiment 3

[0076] Embodiment 3: high anti-acid rain erosion concrete admixture, it is mainly prepared from ground slag, high calcium fly ash, silica fume, polymer, organic fiber and functional strengthening component materials, and the weight parts of each raw material The numbers are: ground slag: 100 parts, high-calcium fly ash: 250 parts, silica fume: 40 parts, the addition amount of polymer, organic fiber and functional strengthening component is respectively ground slag, high-calcium fly ash and 3%, 1.5% and 6% of the total mass of silica fume; the functional strengthening component is composed of an activator and a dispersant at a mass ratio of 1:0.03, and the activator is alkali silicic acid with a solid solution ratio of 1:2 A binary system composed of saline solution and sodium hydroxide at a mass ratio of 1:0.08; the dispersant is a polycarboxylate hyperdispersant with a solid content of 30%.

[0077] The ground slag is selected from the commercially available blast furnace wat...

Embodiment 4

[0084] Embodiment 4: high anti-acid rain erosion concrete admixture, it is mainly prepared from ground slag, high calcium fly ash, silica fume, polymer, organic fiber and functional strengthening component materials, and the weight parts of each raw material The numbers are: ground slag: 100 parts, high-calcium fly ash: 180 parts, silica fume: 15 parts, and the addition amounts of polymer, organic fiber and functional strengthening components are respectively ground slag, high-calcium fly ash and 4.5%, 1% and 4.5% of the total mass of silica fume; the functional strengthening component is composed of an activator and a dispersant at a mass ratio of 1:0.07, and the activator is alkali silicic acid with a solid solution ratio of 1:1.5 A binary system composed of saline solution and sodium hydroxide at a mass ratio of 1:0.1; the dispersant is a polycarboxylate hyperdispersant with a solid content of not less than 30%.

[0085] The ground slag is selected from the commercially ava...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com