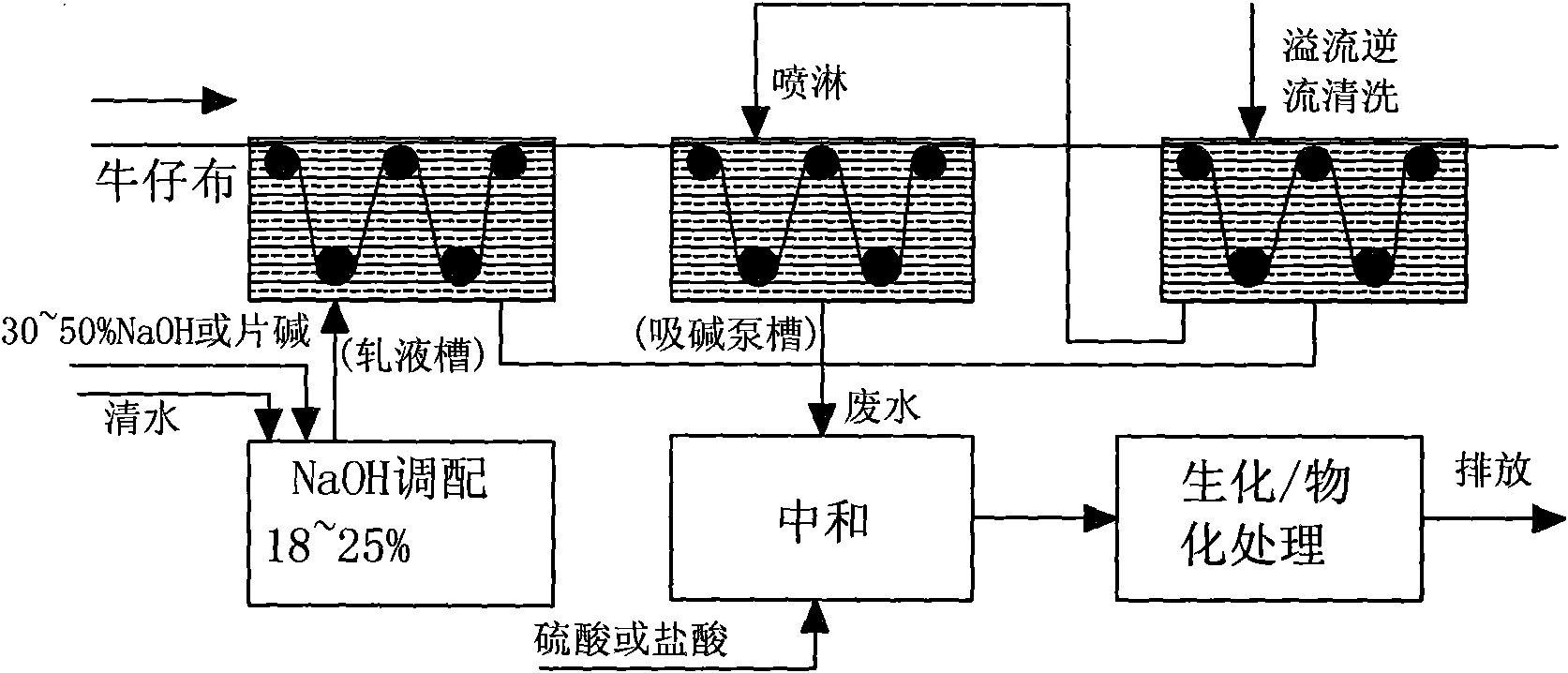

Technical method for purifying and reutilizing jean silkete alkali waste liquid by membrane method

A process method and technology of waste lye, applied in chemical instruments and methods, mercerizing, textile material treatment, etc., can solve problems such as inability to process, achieve the effects of reducing usage, reducing the load of treatment facilities, and enhancing biochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

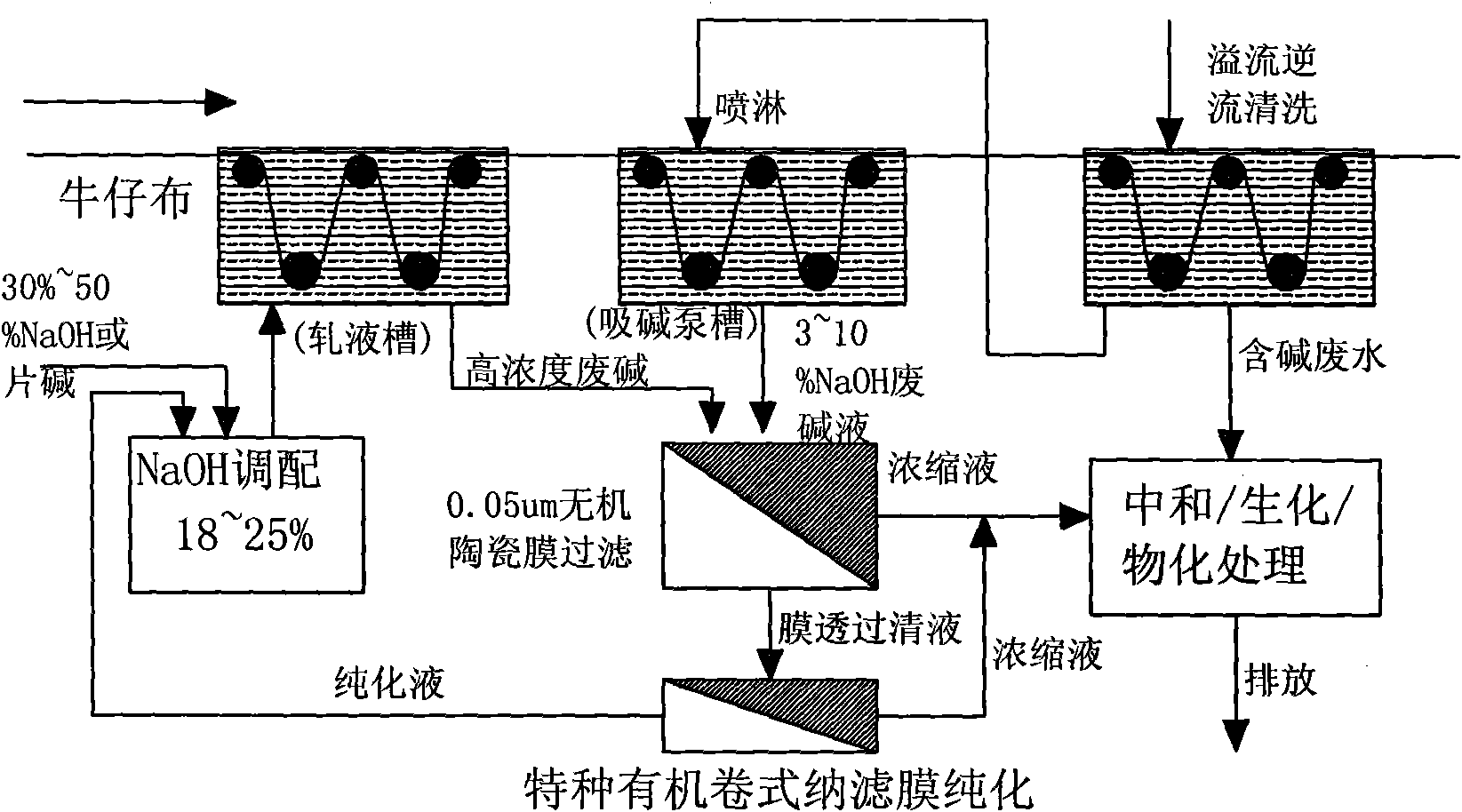

Embodiment 1

[0026] according to figure 2 As shown, the present invention collects the high-concentration lye when refueling the rolling tank of soaked denim and the high-concentration waste lye of the spray alkali-absorbing pump tank during the denim mercerizing process, and uses the collected waste lye after mixing The inorganic ceramic ultrafiltration membrane with a filtration accuracy of 0.05 microns is used for filtration to remove fibers, particulate impurities, and most other insoluble substances such as colloids. Collect the filtered waste alkali liquid, then pass the collected waste alkali liquid through high-precision bag filter, pressurize it through a high-pressure pump, enter the special alkali-resistant nanofiltration membrane for separation and purification, and remove dyes, paddles, Small molecular organic matter, other small molecular impurities, and most inorganic salts with divalent or higher valence. The above-mentioned purified alkali is blended with NaOH liquid or ...

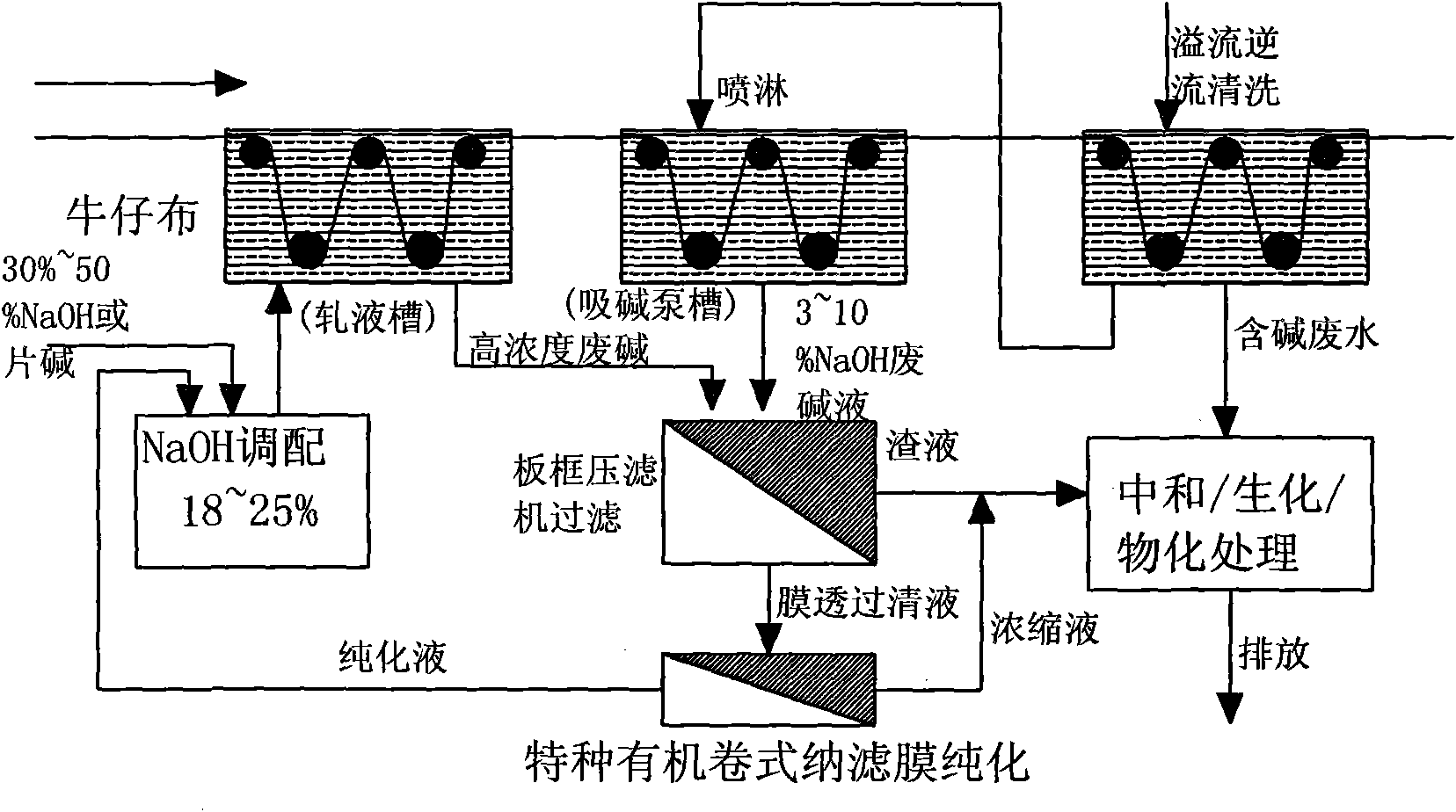

Embodiment 2

[0028] according to image 3 As shown, the present invention mixes the waste lye and the high-concentration waste lye of the spray alkali suction pump tank during the denim mercerizing process, and the collected waste lye is used to Frame filter press is filtered, removes other insoluble matter such as fiber, particle impurity and most colloids, collects the clear liquid after filtering, collects the waste lye clear liquid after filtering, adopts the follow-up treatment identical with embodiment 1 again Just the process.

Embodiment 3

[0030] according to Figure 4 As shown, the present invention mixes the spent lye and the high-concentration spent lye of the spray alkali-absorbing pump tank during the denim mercerizing process, and the collected waste lye is filtered Inorganic ceramic microfiltration membrane with a precision of 0.05 microns is used for filtration to remove fibers, particulate impurities, and most other insoluble substances such as colloids. 0-20%, the cut-off molecular weight of 100-1000Da organic roll-type nanofiltration separation membrane to further purify the waste lye, remove dyes, small molecular organics, other small molecular impurities, most of the divalent and divalent lye in the waste lye Inorganic salt above valence, the purified lye is evaporated to reach the NaOH concentration required by the rolling bath on the mercerizing line, and applied to the mercerizing production line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com