Process for machining L-shaped angular ring

A technology of corner rings and process rings, which is applied in the field of manufacturing connecting parts, that is, L-shaped corner rings, can solve the problems of difficulty in ensuring dimensional accuracy and easy deformation, and achieve the effects of convenient application, increased strength, and improved processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

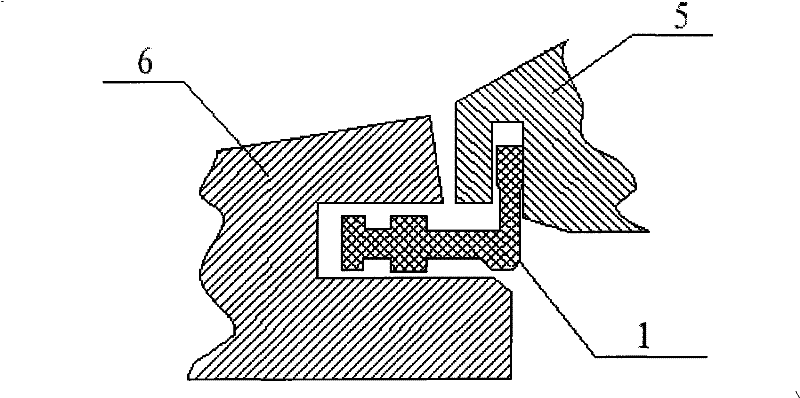

[0019] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

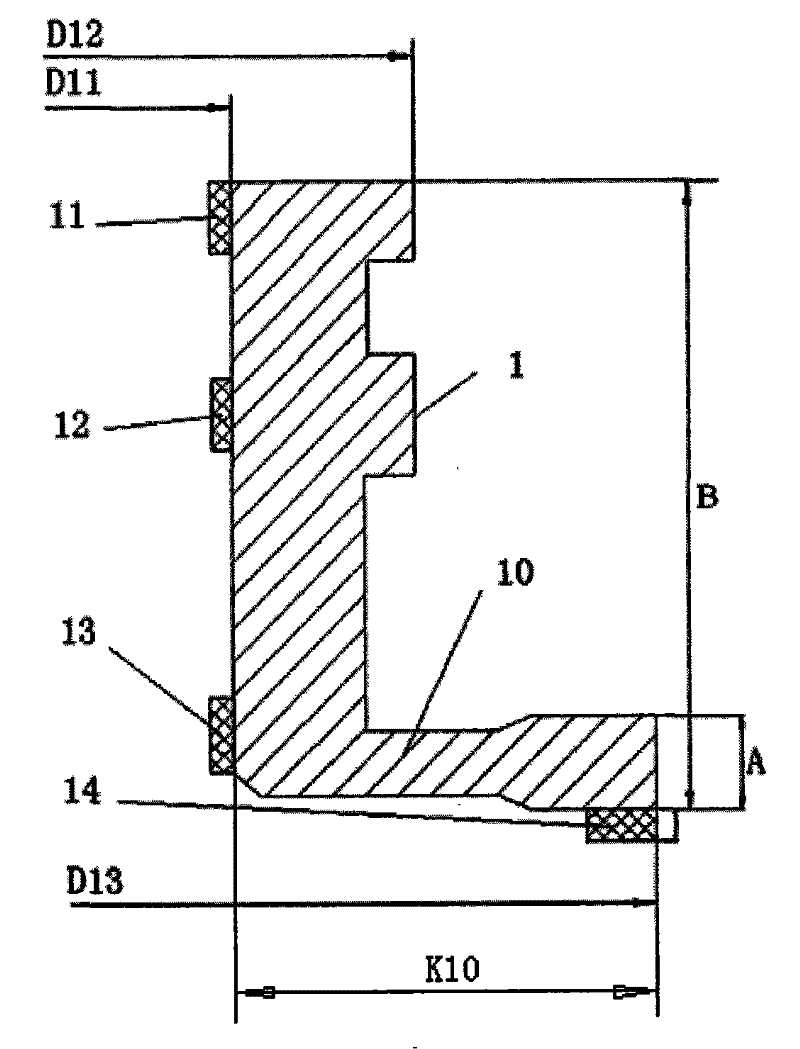

[0020] see figure 2 , the height of the L-shaped corner ring 1 is B, the inner diameter is D11, the outer diameter is D12, the outer diameter of the horizontal portion 10 is D13, the width K10=D13-D11 of the horizontal portion 10, and the thickness of the horizontal portion 10 is a. Stelling alloys 11, 12, and 13 are surfacing at three places on the inner circumference of the L-shaped angle ring 1, and Stelling alloy 14 is surfacing at one place on the lower bottom surface of the horizontal portion 10 of the L-shaped angle ring 1.

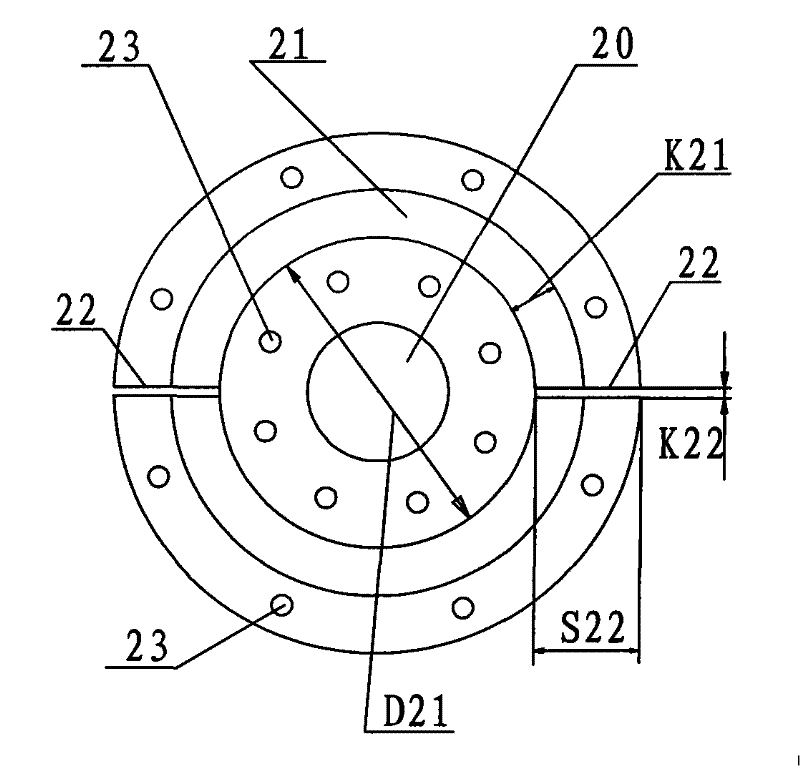

[0021] see again Figure 3a and Figure 3b , a kind of anti-deformation process ring 2 for processing L-shaped corner rings of the present invention, it is a circular ring with an effective thickness and a mounting hole 20 in the center, one surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com