Two-stage press forging and forming method of metal thin shell piece with inward convex micro-structure

A metal thin and convex technology, applied in metal processing equipment and other directions, can solve the problems of slow production speed, low yield rate, casting surface holes and poor mechanical properties, etc., to achieve good forming quality, low forming load, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, the grade of magnesium alloy is AZ31B, and the two-pass hot stamping and forging forming method of magnesium alloy thin shell parts, the specific process and steps are as follows:

[0044] (1) Heat the mold to 400°C;

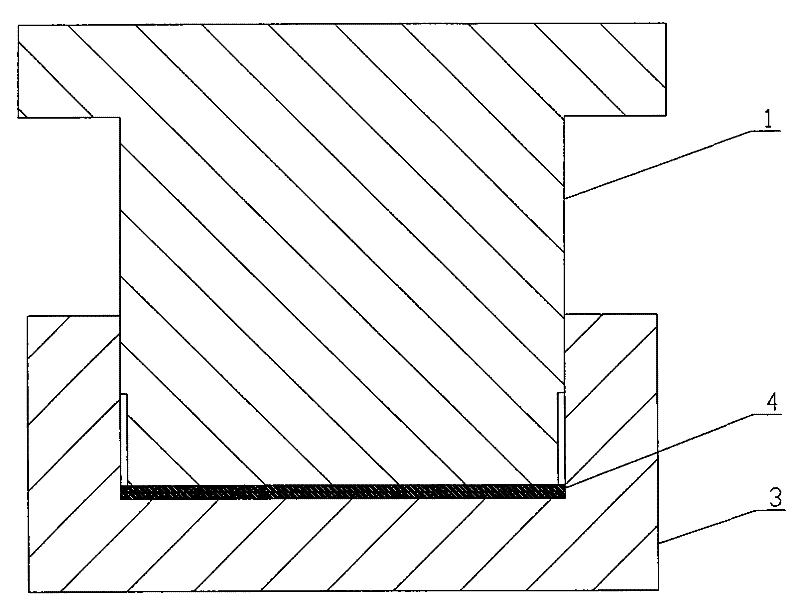

[0045] (2) After polishing the first pass blank 4 (extruded plate or rolled plate) with a thickness of 4.0mm, it is coated with a mixture of graphite and silicone oil. In the present embodiment, the weight percentage of graphite is 15%;

[0046] (3) heating the blank 4 of the first pass to 450°C;

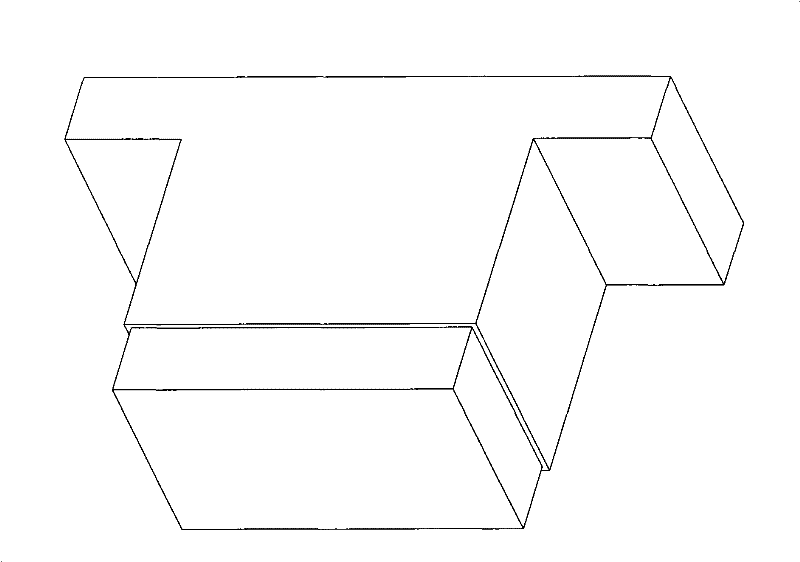

[0047] (4) Put the blank 4 of the first pass into the cavity 3 of the die, and the punch 1 of the first pass moves downward with a reduction of 1.2 mm to form a shell part with a part of the side wall (that is, the second pass blank 5);

[0048] (5) The temperature of the second pass billet 5 is reduced to 400°C;

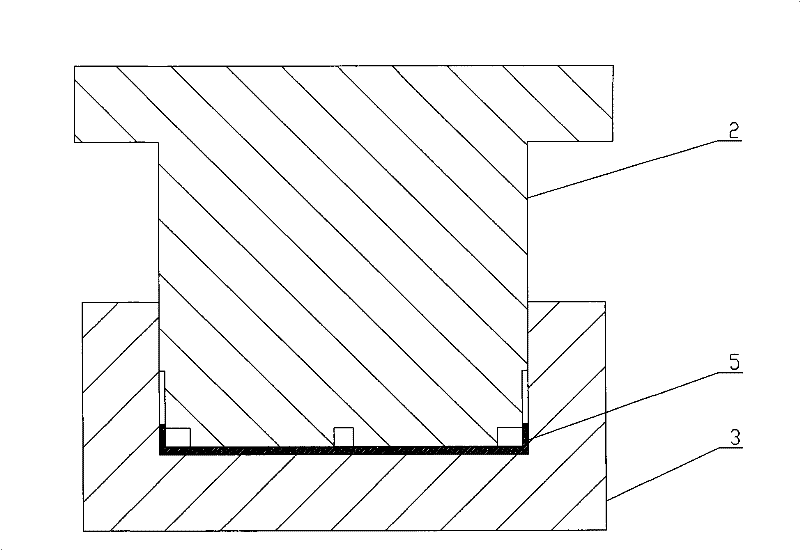

[0049](6) Use the punch 2 of the second pass, and the punch 2 of the second pass moves downward with a reduction of 1.8 mm to...

Embodiment 2

[0058] The difference from Example 1 is:

[0059] In this embodiment, the grade of magnesium alloy is ZK60A, and the two-pass hot stamping and forging forming method of magnesium alloy thin shell parts, the specific process and steps are as follows:

[0060] (1) Heat the mold to 200°C;

[0061] (2) After polishing the first pass blank (extruded plate or rolled plate) with a thickness of 1.5mm, the mixture of molybdenum disulfide and graphite is coated. In the present embodiment, the weight percentage of molybdenum disulfide is 80% ;

[0062] (3) Heating the blank for the first pass to 250°C;

[0063] (4) Put the blank of the first pass into the die cavity, the punch of the first pass moves downward, and the reduction is 0.4mm, and a shell part with a part of the side wall is formed (that is, the blank of the second pass );

[0064] (5) Lower the temperature of the blank in the second pass to 200°C;

[0065] (6) Use the punch of the second pass, and the punch of the second...

Embodiment 3

[0068] The difference from Example 1 is:

[0069] In this embodiment, the grade of aluminum alloy is 1050, and the two-pass stamping and forging forming method of aluminum alloy thin shell parts, the specific process and steps are as follows:

[0070] (1) be coated with the mixture of talc powder and animal oil after polishing the first pass blank (extruded plate or rolled plate) with a thickness of 3mm; in the present embodiment, the weight percentage of talcum powder is 10%;

[0071] (2) Put the blank of the first pass into the cavity of the die, the punch of the first pass moves downward, and the reduction is 0.8mm, and a shell part with a part of the side wall is formed (that is, the blank of the second pass );

[0072] (3) Use the punch of the second pass, and the punch of the second pass moves downward with a reduction of 1.5 mm to form a complete side wall and a shell with an internal convex microstructure.

[0073] The punched and forged parts are trimmed and then ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com