Method for preparing skin-free homogeneous structural polyvinylidene fluoride transfer film

A technology of polyvinylidene fluoride and transfer membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve uniform pore size, stable structure and performance, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

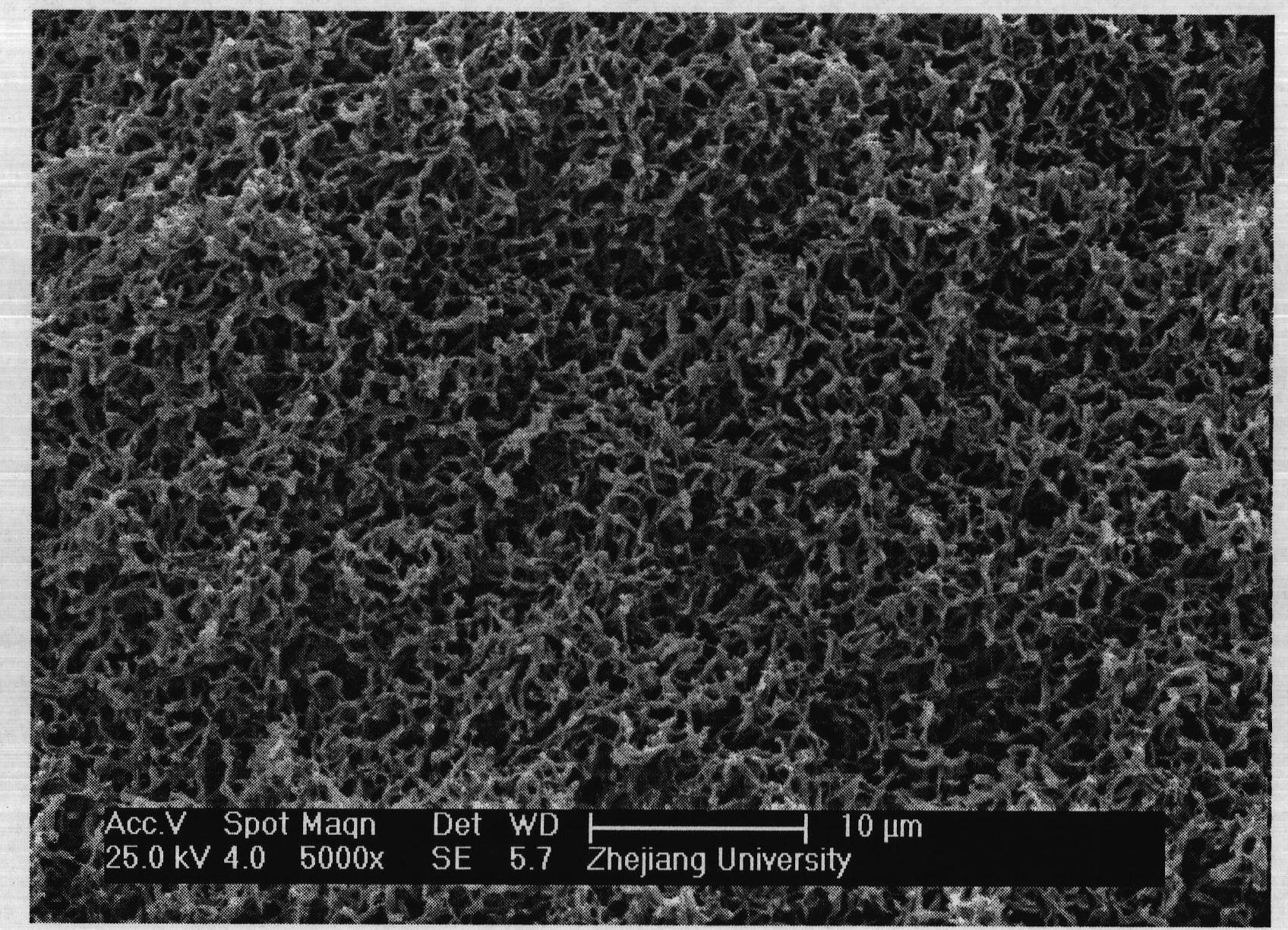

Embodiment 1

[0038] PVDF (viscosity average molecular weight M v =431,000g / mol) was dissolved in the mixture of triethyl phosphate and ethanol at 90°C, the weight ratio of raw materials was: PVDF: triethyl phosphate: ethanol=15:82:3, stirred until PVDF was completely dissolved , after standing for defoaming, scrape it on a clean and flat glass plate with a scraper. Immerse the scraped film liquid in the first gel bath for 10 minutes, the first gel bath temperature is 20°C, the composition of the gel bath is: the mass percent concentration is an aqueous solution of 75% triethyl phosphate, to obtain nascent ecology membrane. The nascent membrane was then immersed in a second gel bath containing only deionized water at 20°C for 2 hours. Finally, the membrane was rinsed with tap water at room temperature for more than 24 hours to completely exchange the solvent. Dry the membrane after rinsing at room temperature to obtain a microporous membrane with a certain pore size distribution. The str...

Embodiment 2

[0043] PVDF (viscosity average molecular weight M v =431,000g / mol) was dissolved in the mixture of dimethylformamide and ethanol at 70°C, the weight ratio of raw materials was: PVDF: dimethylformamide: ethanol = 16 ~ 81 ~ 3, stirred until PVDF Dissolve completely, let it stand for defoaming, and then scrape it on a clean and flat glass plate with a spatula. Immerse the scraped membrane solution in the first gel bath for 10 minutes, the temperature of the first gel bath is 20° C., and the composition is an aqueous solution with a mass percentage concentration of 60% dimethylformamide to obtain a nascent membrane. Then the nascent film was immersed in the second gel bath with a temperature of 40° C. and an aqueous solution with a concentration of 10% dimethylformamide by mass for 2 hours. The following steps are the same as Example 1. The results obtained are shown in Table 2 and attached image 3 , Figure 4 .

[0044] The various performances of the prepared membrane of t...

Embodiment 3

[0047] PVDF (viscosity average molecular weight M v =789,000g / mol) was dissolved in triethyl phosphate at 80°C, the weight ratio of raw materials was: PVDF:triethyl phosphate=16:84, stirred until the PVDF was completely dissolved, and scraped with a scraper after standing for defoaming on a clean, flat glass plate. The following steps are the same as Example 1. The structure of the obtained membrane is as Figure 5 , Figure 6 As shown, the performance test results are shown in Table 3.

[0048] The various performances of the prepared membrane of table 3 embodiment 3

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com