Waste heat sharing intensive tobacco flue-curing house and operating method thereof

A technology of flue-cured tobacco room and waste heat, which is applied in the fields of application, tobacco, and tobacco preparation, etc. It can solve the problems of harsh working environment of baking operation, non-recyclable residual heat, and low density of smoke in the curing room, so as to reduce the labor intensity of the stoker, The effect of reducing the cost of baking moisture and reducing the cost of the baking room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

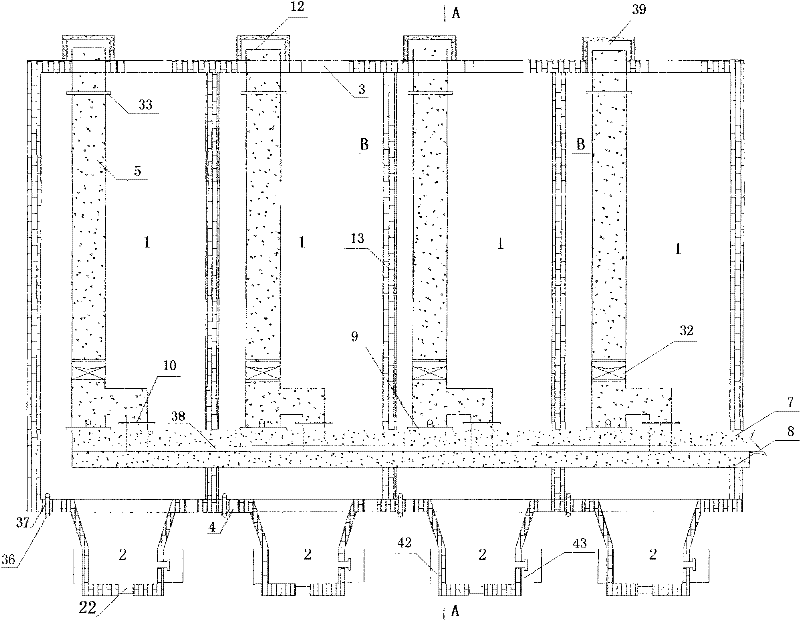

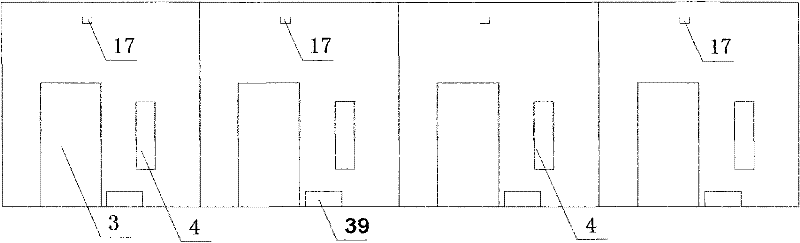

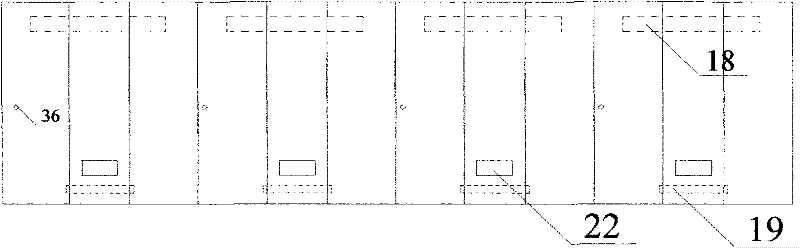

[0041] like Figure 1-9 As shown, the waste heat sharing intensive flue-curing room is composed of several flue-curing rooms 1 connected as a whole, and the adjacent flue-curing rooms 1 are separated by a public partition wall 13 arranged longitudinally; Corresponding heating chamber 2, the flue-curing chamber 1 and the heating chamber 2 are separated by a common partition wall arranged horizontally; the flue-curing chamber 1 is provided with a moisture exhaust channel 5 and a residual heat sharing channel that seals and communicates the flue-curing chambers 1, and the residual heat is shared. The channel is composed of a waste heat heating channel 7 and a waste heat regain channel 8. The waste heat heating channel 7 and the waste heat recovery channel 8 are arranged in parallel in the flue-cured tobacco room 1. The waste heat heating channel 7 and the waste heat regain channel 8 share the channel partition wall 38 with waste heat. Tightly spaced; the waste heat heating channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com