Tobacco leaf separating type needle-threading tobacco packing and suspending method

A technology of separation and tobacco leaves, applied in the direction of tobacco, tobacco preparation, application, etc., to achieve the effect of reducing disability rate, standardization of density, and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

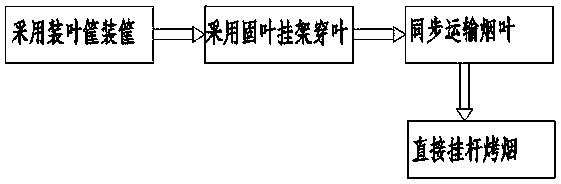

[0032] Such as figure 1 As shown, Embodiment 1 of the present invention, a kind of tobacco leaf separation type threading needle loaded tobacco suspension method, comprises the following steps:

[0033] A. Use a leaf-loading basket to load the basket: put the collected loose tobacco leaves with their petioles facing upwards and leaf tips facing down, and place them flat in the leaf-loading basket. Full; B. Use the leaf-fixing hanger to wear the leaves: press the leaf-fixing hanger that is equipped with the leaf-piercing needle and cooperate with the leaf-loading basket downward into the leaf-loading basket, and the leaf-piercing needle is under the pressure of the external force and the self-weight of the leaf-fixing hanger. Under the action, penetrate into the tobacco leaves, and put all the tobacco leaves on the leaf-piercing needle; C. Simultaneously transport the tobacco leaves: take out the solid leaf hanger with the tobacco leaves alone or place it on the transport vehic...

Embodiment 2

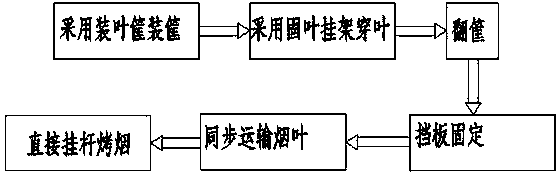

[0035] Such as figure 2 As shown, Embodiment 2 of the present invention, a method for hanging tobacco leaves through needles and loading cigarettes with separated tobacco leaves, includes the following steps:

[0036]A. Use a leaf-loading basket to load the basket: put the collected loose tobacco leaves with their petioles facing upwards and leaf tips facing down, and place them flat in the leaf-loading basket. Full; B. Use the leaf-fixing hanger to wear the leaves: press the leaf-fixing hanger that is equipped with the leaf-piercing needle and cooperate with the leaf-loading basket downward into the leaf-loading basket, and the leaf-piercing needle is under the pressure of the external force and the self-weight of the leaf-fixing hanger. Under the action, penetrate into the tobacco leaves, and put all the tobacco leaves on the leaf-piercing needle; B1 turning over the basket: turn over the leaf basket, tobacco leaves and leaf-fixing rack that have been matched together. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com