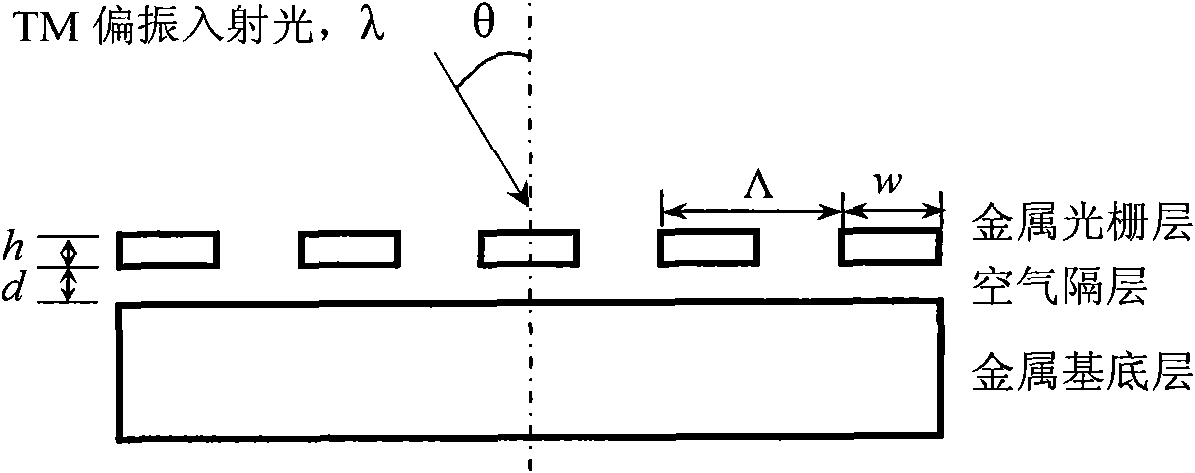

Gas refracting index sensor based on nanometer cavity antenna array

A technology of gas refractive index and cavity antenna, applied in the field of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Metal composite structures with enhanced transmission efficiency of nanoslits were fabricated by nanoimprinting, reactive ion assisted etching, physical sputtering, focused ion beam and electron beam lithography. The production process proceeds in the following steps:

[0019] First, a 30-nanometer-thick quartz layer is plated on a metallic silver substrate.

[0020] Then, spin-coat a layer of polymethyl methacrylate (PMMA) with a thickness of 20 nanometers on the quartz layer, heat it to 200°C (105°C higher than the glass transition point of polymethyl methacrylate), and place the prefabricated A silica template (with a grating pattern with a period of 1100 nm, a duty ratio of 0.5, and a depth of 20 nm) was pressed into the polymethylmethacrylate at a pressure of 15 MPa. At this time, polymethyl methacrylate is higher than its glass transition point temperature of 105 ° C, similar to a viscous liquid, and can flow under pressure. Keep the pressure constant, lower the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com