Optical generator

An optical engine, cylinder block technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problem of no engine combustion chamber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Referring to the embodiments shown in the accompanying drawings, the specific content and implementation of the present invention will be further described.

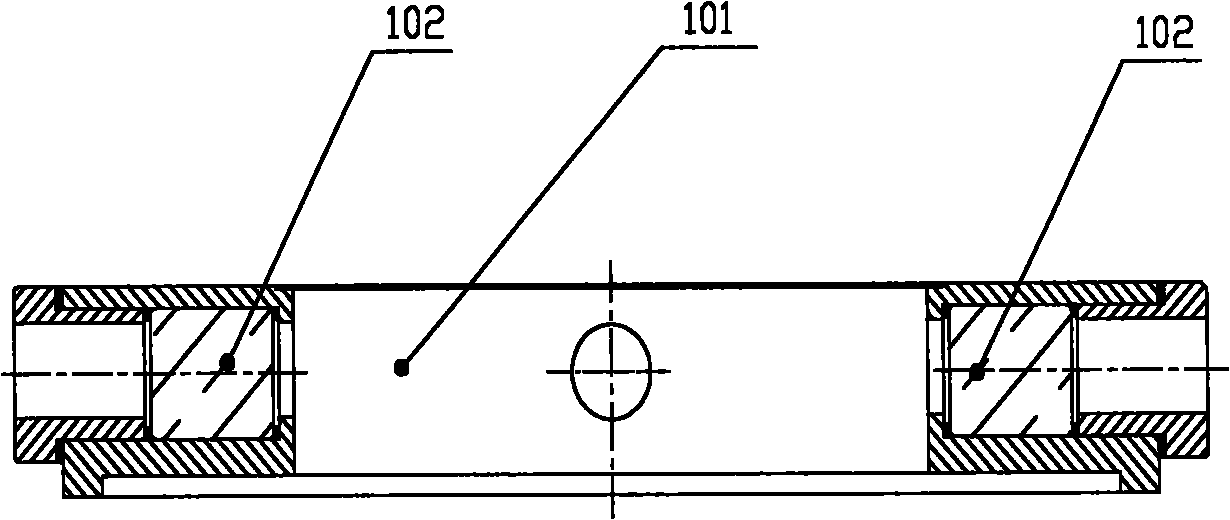

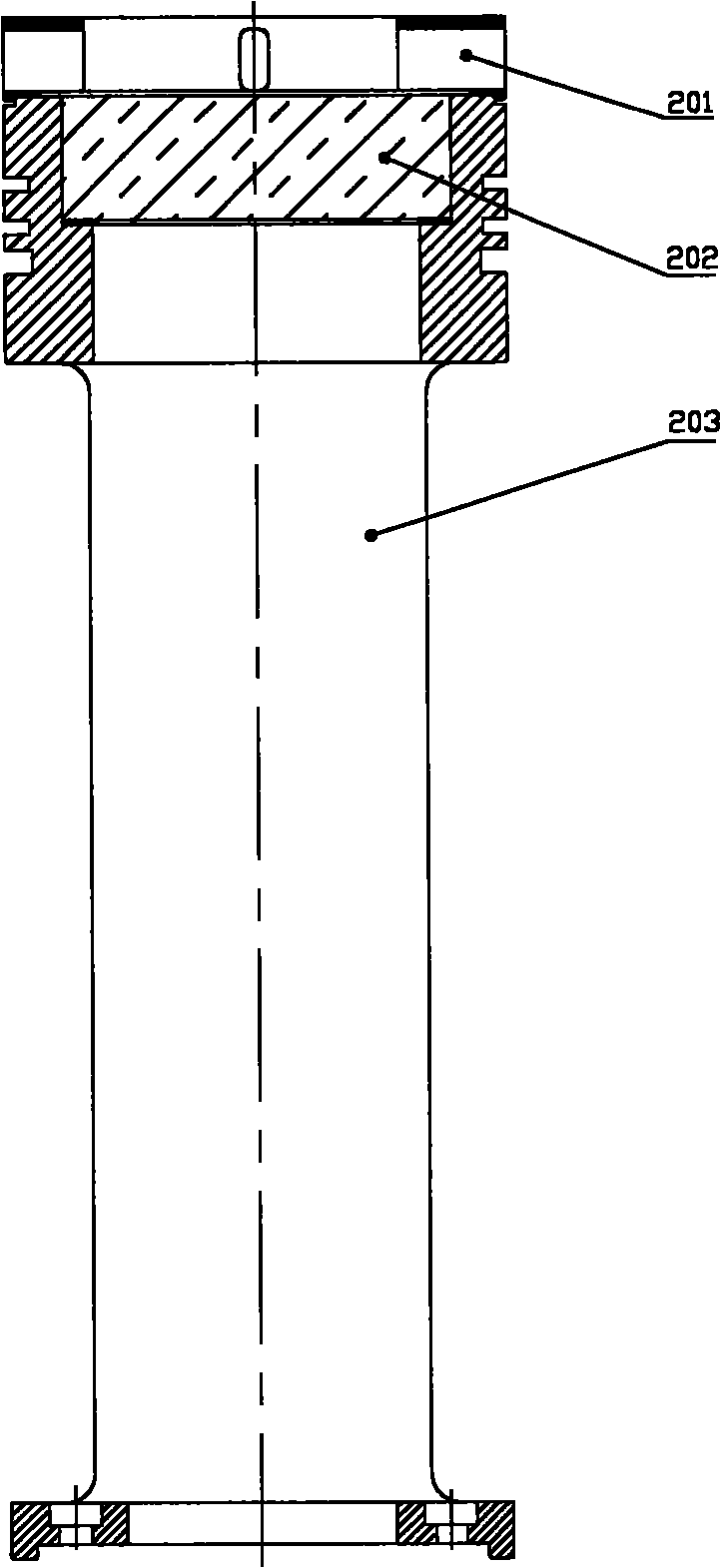

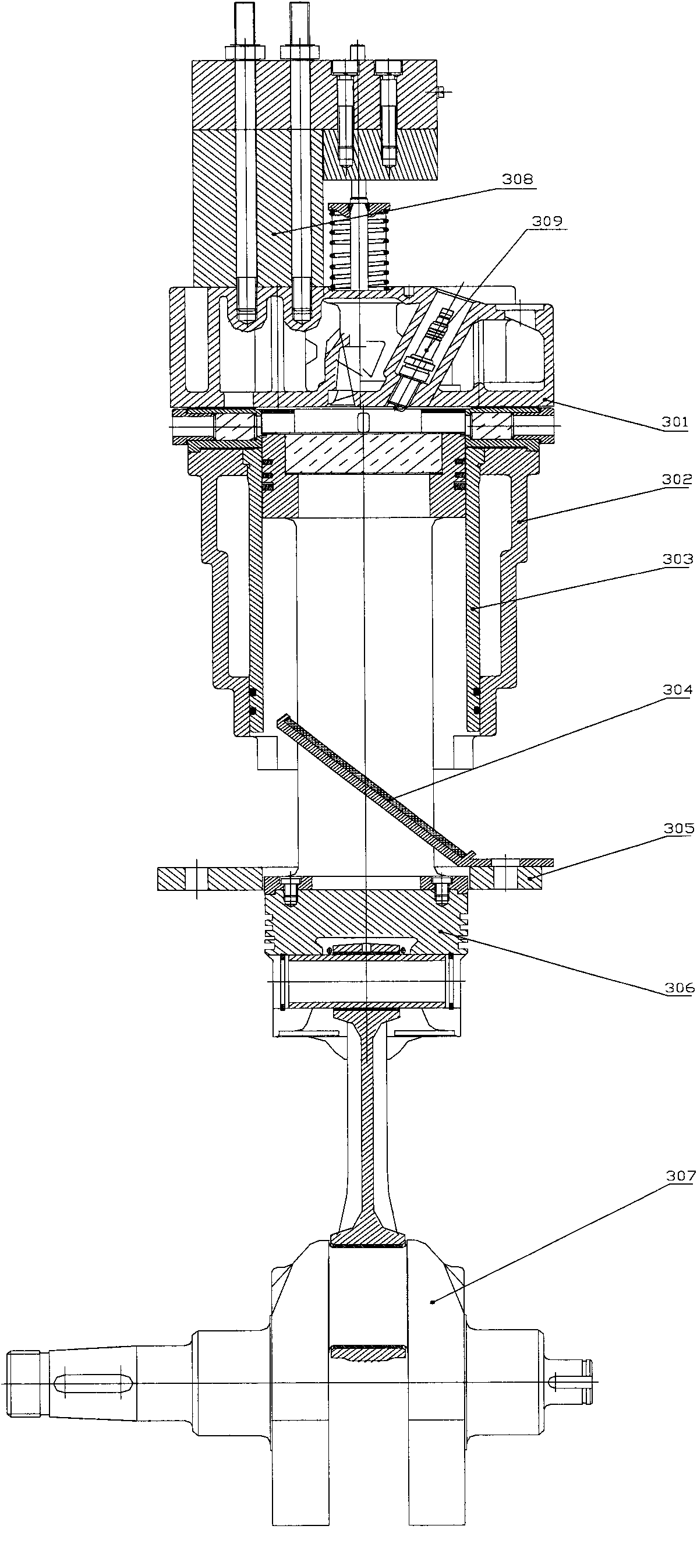

[0045] In the optical engine of the present invention, a ring gasket is arranged between the lengthened cylinder body and the cylinder head, and four laser transparent windows that can enter the laser beam are installed on the positions perpendicular to each other in the radial direction of the ring gasket; The upper part is provided with a combustion chamber that is as large as possible and has a certain shape, and there is a transparent window for the combustion chamber that can be used to observe the movement of the working fluid and the combustion process; The reflector on the body is at an angle of 45° to the piston axis; there is a cooling water jacket in the extended cylinder body, and hot water is supplied to the cooling water jacket through a temperature-controllable circulating cooling water tank; A fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com