Novel environment-friendly water-based plastic track

A plastic runway, environmentally friendly technology, applied in the direction of roads, roads, buildings, etc., can solve the problems that water cannot exist on the concrete or asphalt base surface, affect the performance of the runway after polyurethane mesh, and have high moisture and humidity requirements, and achieve construction efficiency. High, high strength, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

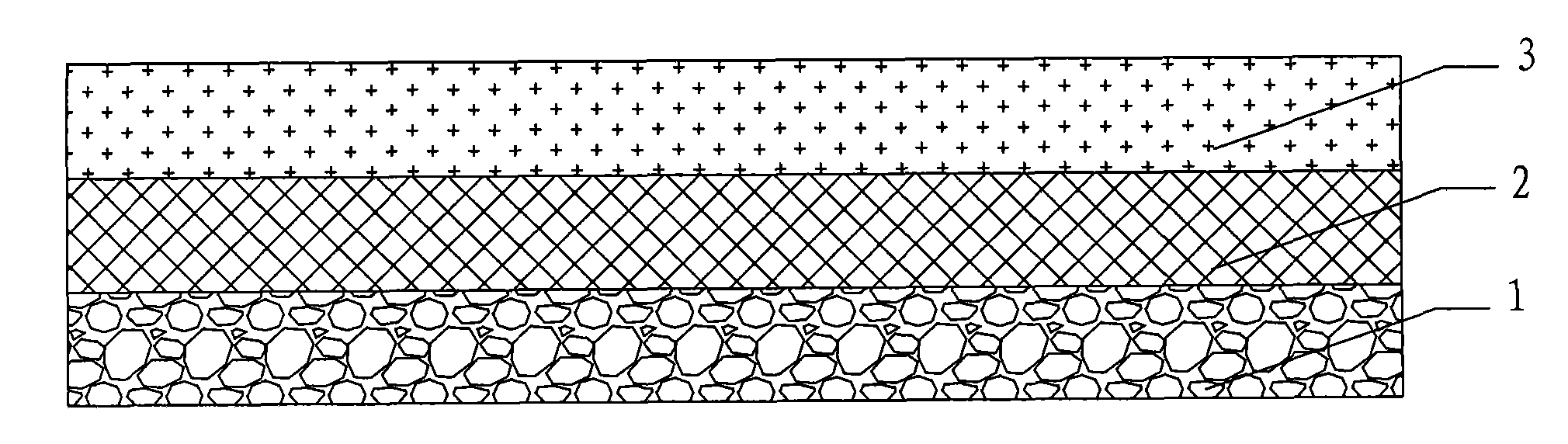

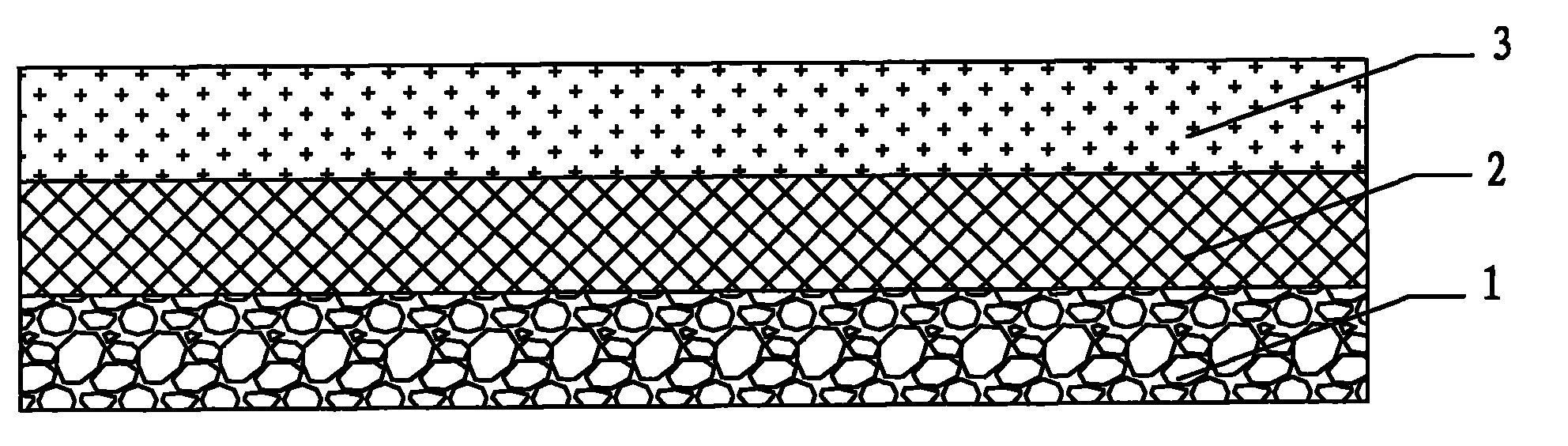

[0027] Embodiment 1: see figure 1 As shown, it is a new type of environmentally friendly water-based plastic runway, including three-layer structure: the base layer 1 is a concrete or asphalt structure; Emulsion, 100 parts by mass of black waste rubber particles with a particle size of 3 mm, 6-12 parts by mass of water and 0.05-0.10 parts by mass of elastic layer additives are fully mixed, spread on the base layer 1, and heated at room temperature to 50 It is solidified under the condition of ℃; the anti-skid surface layer 3 is made of 6-10 parts by mass of white cement, 14-22 parts by mass of water-based polymer emulsion, 5-9 parts by mass of water, 0.20-0.30 parts by mass of pigment and 0.05- 0.10 parts by mass of anti-skid layer additives are fully stirred to obtain the slurry, spread on the plastic elastic layer 2, and spray 30-40 parts by mass of colored EPDM particles with a particle size of 2-4mm, at room temperature to 50°C After solidification, a new type of environm...

Embodiment 2

[0028] Example 2: Making a plastic runway with a thickness of 13mm

[0029]1. Preparation of the plastic elastic layer 2: Weigh 1500g of waste rubber particles, 110g of cement, 330g of styrene-acrylic acid copolymer emulsion, 90g of water, and corresponding additives, which are plasticizers added at a mass ratio of 1:1:1. Agent sodium lignosulfonate, antioxidant 2,6-di-tert-butyl-4-methylphenol (BHT referred to as antioxidant 264) and antifungal agent 8-hydroxyquinoline, the total addition amount is 0.75g. Mix the above raw materials evenly, pave and smooth them on the base layer 1 of the asphalt or concrete structure, with a thickness of 10mm and an area of 0.25m 2 , After curing (about 24h), a plastic elastic layer is obtained.

[0030] 2. Preparation of anti-slip surface layer 3: Weigh 90g of white cement, 210g of styrene-acrylic acid copolymer emulsion, 70g of water, 3.0g of iron oxide pigment and corresponding additives, the additives are added in a mass ratio of 1:1:1...

Embodiment 3

[0034] Embodiment 3: Making a plastic runway with a thickness of 8mm

[0035] 1. Preparation of plastic elastic layer: Weigh 1500 waste rubber particles, 210g of cement, 480g of ethylene-vinyl acetate copolymer emulsion, 190g of water, and corresponding additives, which are plasticizers added at a mass ratio of 1:1:1 Polycarboxylate powder, antioxidant tetrakis (4-hydroxyl-3,5-tert-butylphenylpropionic acid) pentaerythritol ester (abbreviated as antioxidant 1010) and antifungal agent 8-hydroxyquinolinone, the total addition is 1.50g. Mix the above raw materials evenly, pave and smooth on the base layer 1 of the asphalt or concrete structure, with a thickness of 5mm and an area of 0.5m 2 , After curing (about 24h), a plastic elastic layer is obtained.

[0036] 2. Preparation of the anti-skid surface layer 3: Weigh 150g of white cement, 330g of ethylene-vinyl acetate copolymer emulsion, 135g of water, 4.5g of iron oxide pigment and 1.60g of corresponding additives, and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com