Anode gradual-entering type microarc oxidation treatment method and device with low energy consumption

A technology of micro-arc oxidation and treatment method, which is applied in the field of devices used in low-energy anode gradual-in micro-arc oxidation treatment and low-energy anode gradual-in micro-arc oxidation treatment method, which can solve the problem of high stress and current overshoot of power devices , Huge waste of resources and other issues, to achieve the effect of reducing energy consumption, avoiding current overshoot, and ensuring power capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] For the processing of large-area single-chip workpieces, the micro-arc oxidation power supply adopts a constant voltage-constant voltage control method.

[0031] Step 1. Preparation stage:

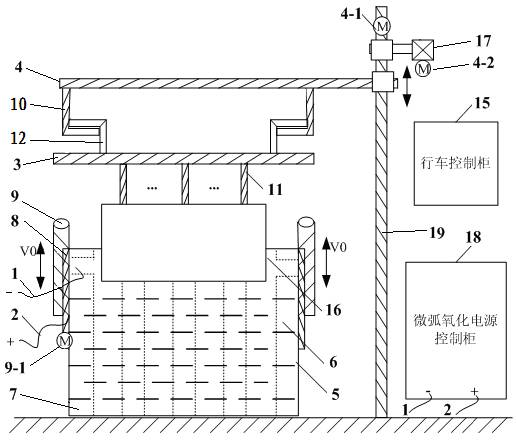

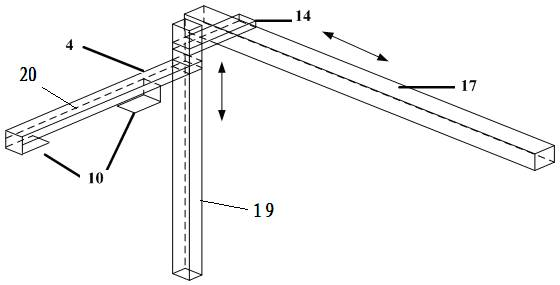

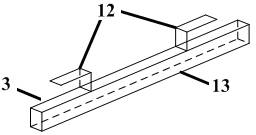

[0032] First, operate the crane control cabinet 15, move the hook 10 of the crane 4 to the workpiece 16 and the flying bus 3 to be loaded, mount the flying bus 3 on the hook 10, and hang the workpiece 16 to be processed through the clamp 11 Connect to flybar 3; make motion slider 9 at the highest position;

[0033] Secondly, operate the driving control cabinet 15, manually lift the hook 10 equipped with the flying bus 3 and the workpiece 16 in the vertical direction, move the driving 4 to the top of the electrolytic cell 5 through the driving shaft 14 in the horizontal direction, and pass the driving beam 20 to make The crane 4 descends slowly into the electrolytic cell 5 along the vertical direction until the flybar main shaft 13 rides on the arc ports of the two copper columns 9-...

Embodiment 2

[0052] For the processing of large-area single-chip workpieces, the micro-arc oxidation power supply adopts a constant voltage-constant current control method.

[0053] The preparatory stage and the post-processing stage are basically the same as in Example 1. In the surface treatment stage, the micro-arc oxidation power supply first applies a critical arc-starting voltage at both ends of the electrode, adopts constant voltage control, and detects the current to adjust the movement of the slider 9. Speed; after the workpiece 16 is completely immersed in the electrolyte 6, the micro-arc oxidation power supply is controlled by a constant current mode to complete the micro-arc oxidation treatment process.

Embodiment 3

[0055] For the processing of large-area single-chip workpieces, the micro-arc oxidation power supply adopts a constant voltage-constant power control method.

[0056] The preparatory stage and the post-processing stage are basically the same as in Example 1. In the surface treatment stage, the micro-arc oxidation power supply first applies a critical arc-starting voltage at both ends of the electrode, adopts constant voltage control, and detects the current to adjust the movement of the slider 9. Speed; after the workpiece 16 is completely immersed in the electrolyte 6, the micro-arc oxidation power supply is controlled by a constant power mode to complete the micro-arc oxidation treatment process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com