Drum machine based on intelligent double closed-loop control and control method thereof

A double closed-loop control, reeling machine technology, applied to electric controllers, controllers with specific characteristics, cardboard wound articles, etc. Problems such as poor consistency of paper tube products, to achieve the effects of low cost, long motor life, and improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

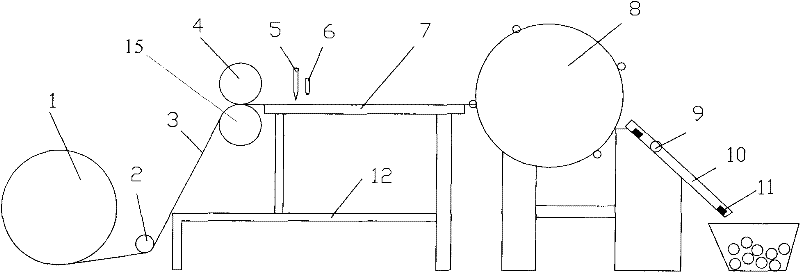

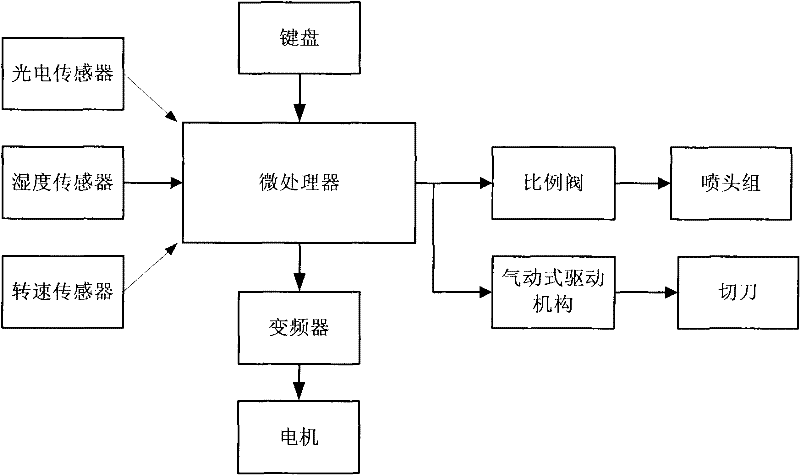

[0041] Such as figure 1 and 3 , a roll machine based on intelligent double closed-loop control, characterized in that it includes a roll mechanism for rolling paper into a roll, a paper feed mechanism for feeding paper to the roll mechanism, and a paper feed mechanism for controlling Microprocessor of the institution; the microprocessor adopts DSP.

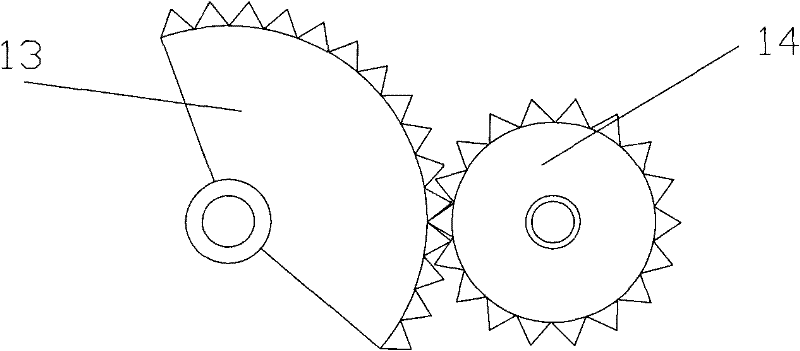

[0042] The paper feeding mechanism includes a frame, a fixed pulley installed at the bottom of the frame, a driving wheel and a pressure wheel for pulling the paper tape, a cutter for cutting the paper tape, and a nozzle for spraying water on one end of the paper group, a motor, a frequency converter for adjusting the motor speed, and an intermittent transmission mechanism for driving the driving wheel; the cutter and nozzle group are arranged above the panel of the frame; the pressing wheel and the driving wheel are arranged on the On the frame; the paper tape drawn from the paper roll goes around the fixed pulley and passes be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com