Method for rapidly making CH hole in manufacturing process of stamping die and device thereof

A stamping die and manufacturing process technology, applied in the field of rapid production of CH holes, can solve the problems of increasing die processing and manufacturing time, increasing die development cost, increasing processing and assembly and debugging workload, etc. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The device for quickly making CH holes in the stamping die manufacturing process includes a stamping die die 1 and a stamping die punch 2 . The method for rapidly making CH holes in the stamping die manufacturing process includes the following steps:

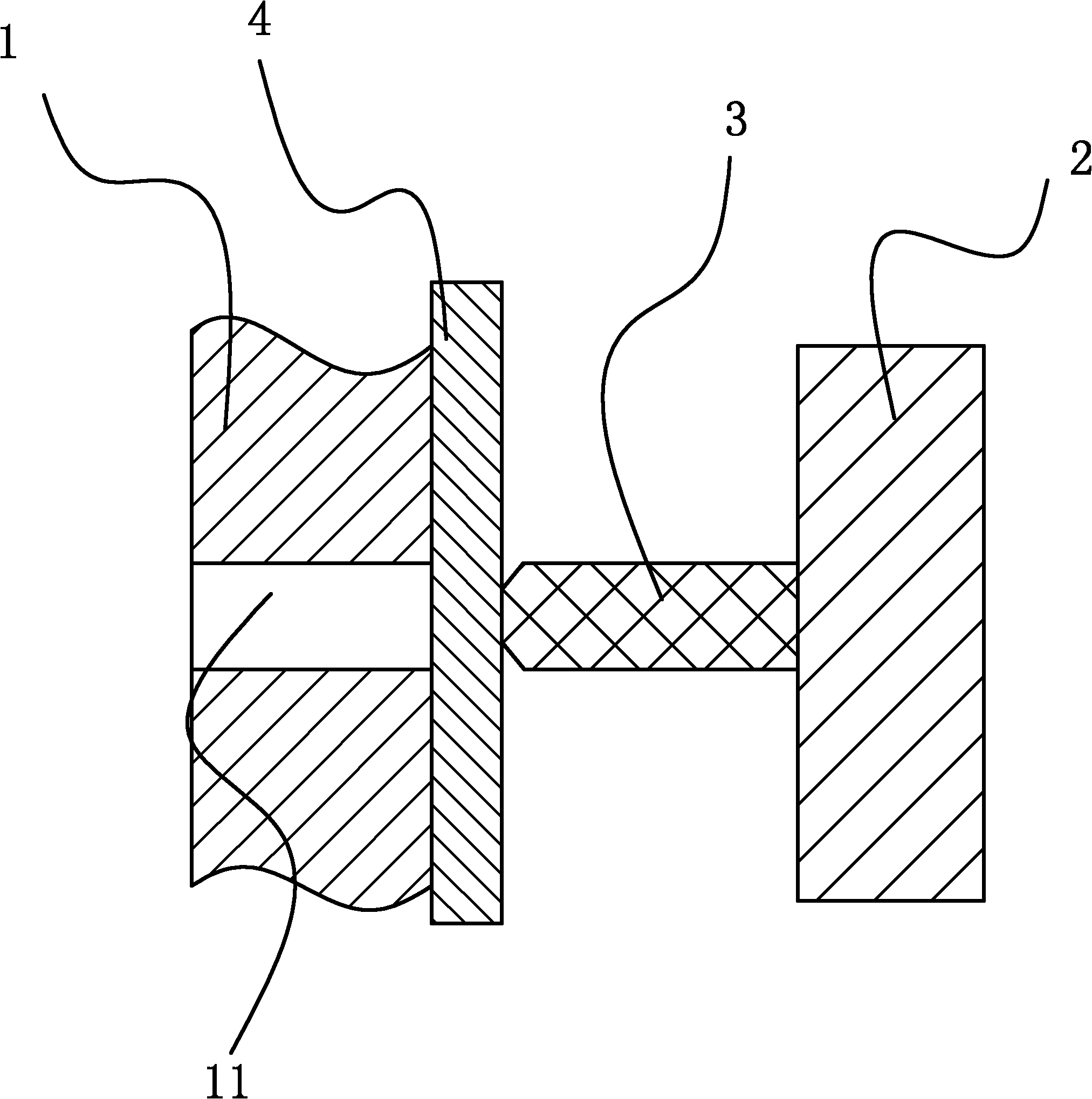

[0025] Such as figure 1 As shown, prepare the concave and convex molds: set several bottom holes 11 on the stamping die die 1, fix several punches 3 corresponding to the bottom holes 11 on the stamping die punch 2, and the punches 3 are made of non- Made of metal elastic material. The punch 3 here is made of urethane glue, and the shape of the punch 3 is adapted to the shape of the bottom hole 11 . The punch 3 is fixed on the stamping die punch 2 by thermoplastic or bonding. The bottom hole 11 is a blind hole and its depth is 11-25mm, and the diameter of the bottom hole 11 is 4-8mm. Generally, the bottom hole 11 has a depth of 20 mm and a diameter of 6 mm.

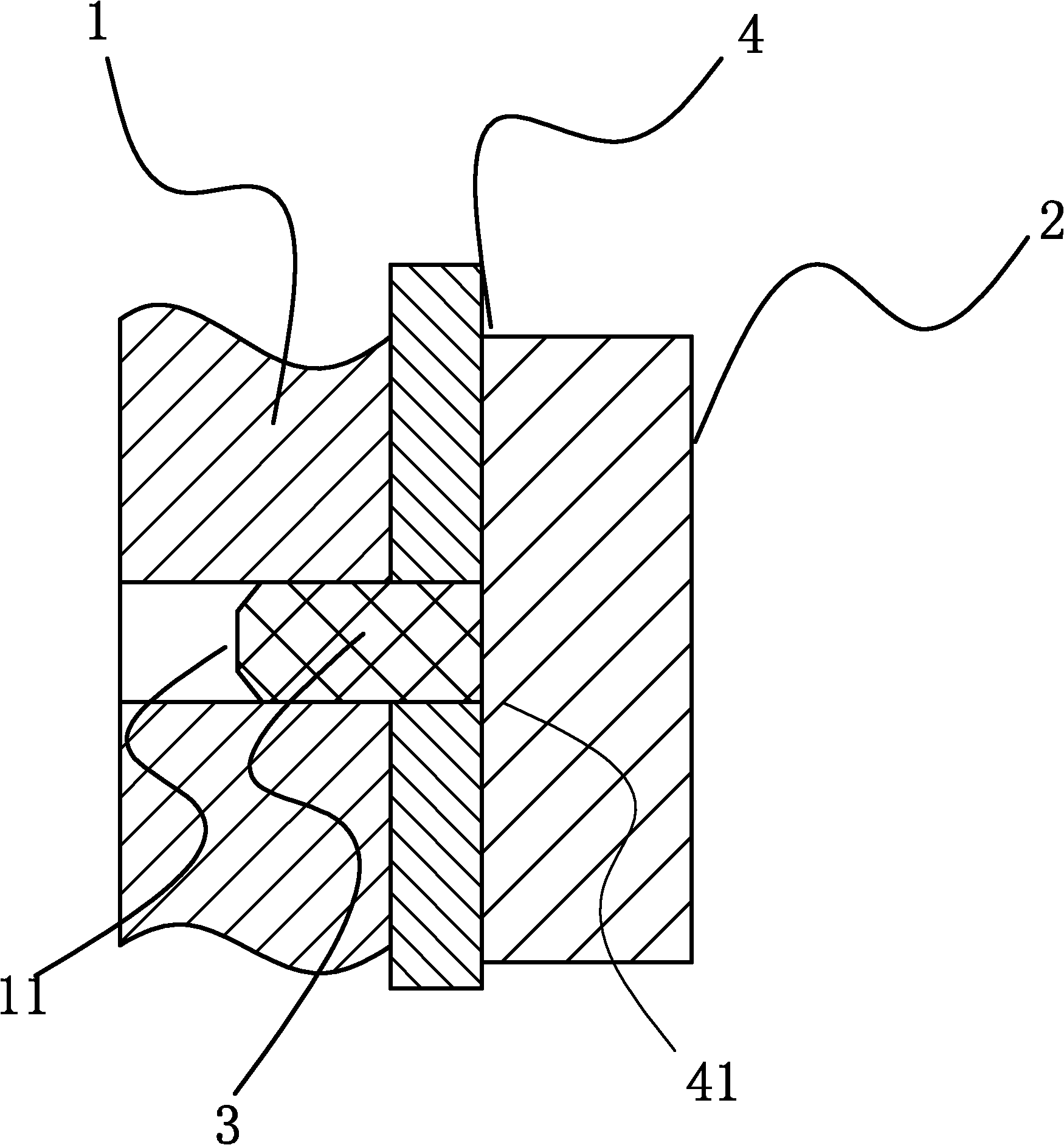

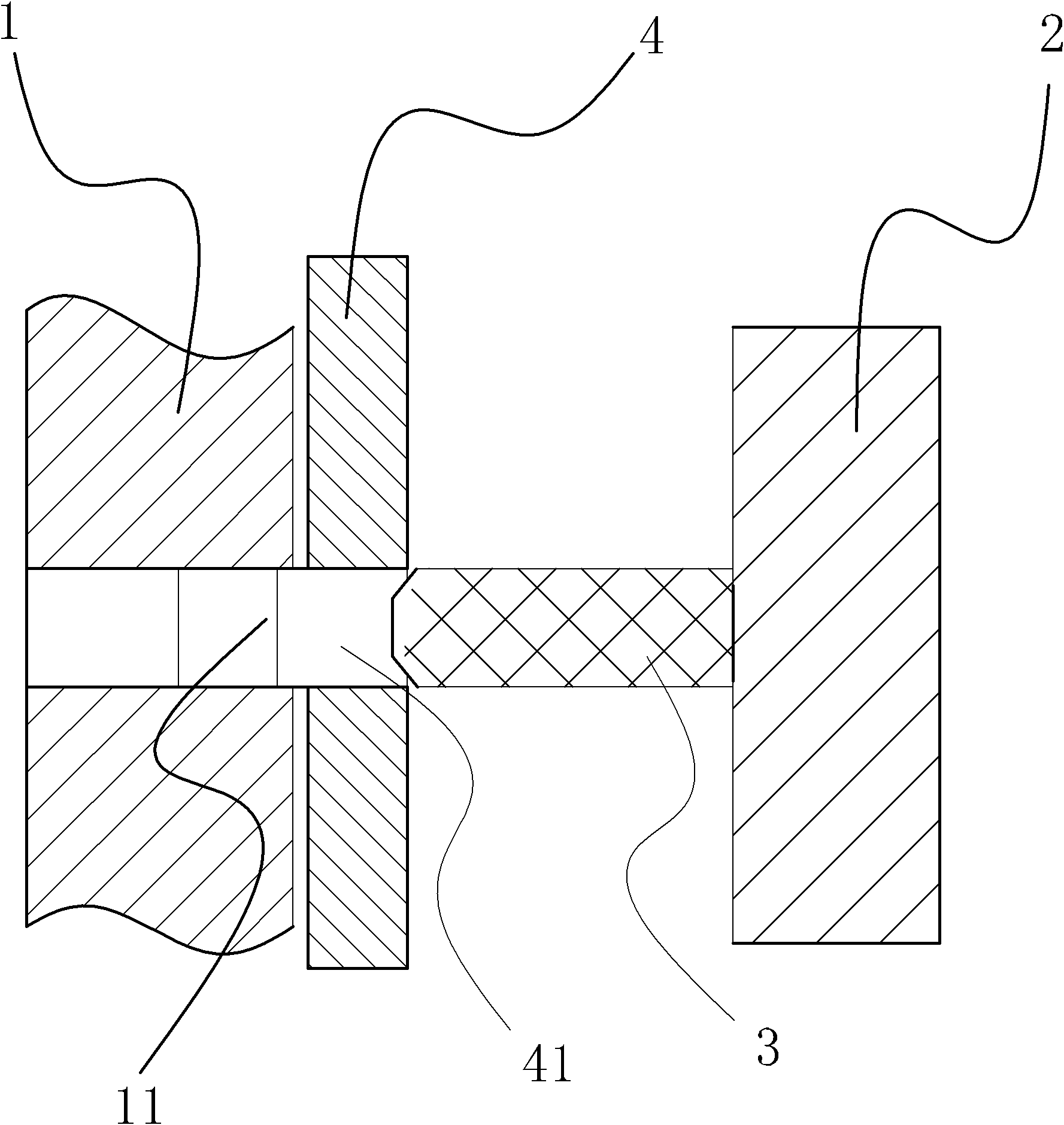

[0026] Such as figure 2 As shown, hole forming: the stamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com