Production process of high-chromium alloy ceramic particle composite grids

A high-chromium alloy and ceramic particle technology, which is applied in metal processing equipment, equipment for feeding molten metal into molds, manufacturing tools, etc., can solve the problem of affecting the service life of equipment, production stability, and unsatisfactory surface wear resistance. problem, to achieve the effect of long cycle and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

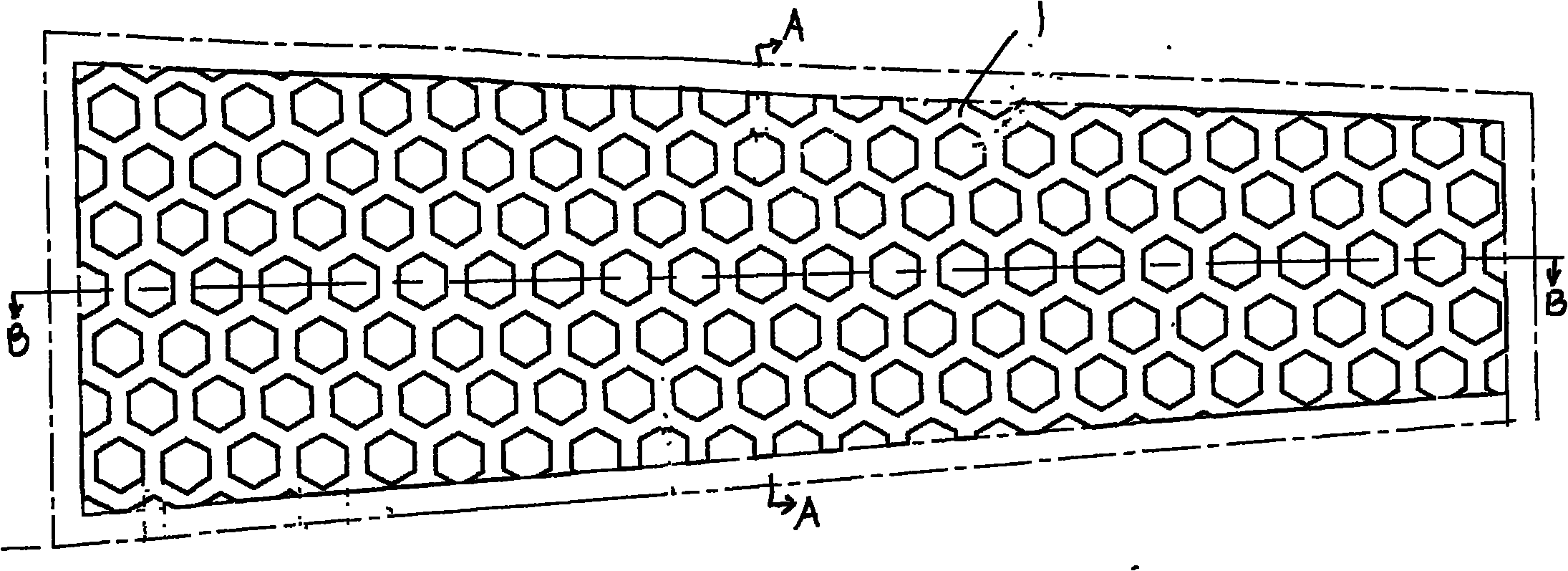

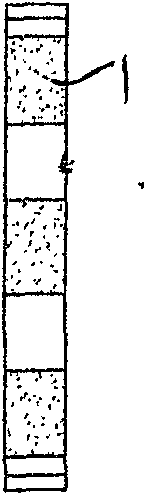

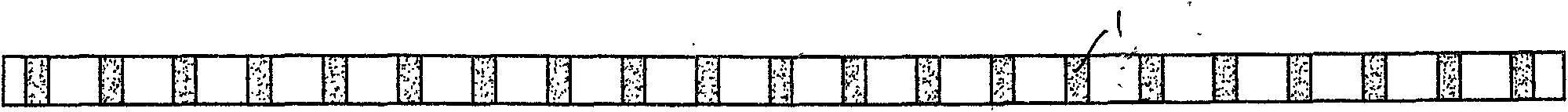

[0015] A production process of a high-chromium alloy ceramic particle composite grid, comprising the following steps in sequence:

[0016] Melt the high chromium alloy and place it in the ladle, add sintered and crushed alumina and / or zirconia particles with a particle size of 80 to 100 mesh in the ladle, stir and mix, inject the mixture into the grid sand mold, and then Cool and take it out to obtain a composite mesh 1 of high chromium alloy ceramic particles.

[0017] The added amount of the alumina and / or zirconia particles is 30%-40% by volume.

[0018] The alumina and zirconia particles are particles with a content of 95% or 99%.

[0019] The specification of the grid sand mold is to make the thickness of the composite grid to be 15-20mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com