Anti-stain coating composition containing copper compound and having improved slime resistance and storage stability

A technology of antifouling coatings and compositions, applied in antifouling/underwater coatings, preservation of human or animal bodies, chemicals used for biological control, etc., can solve nozzle clogging, recrystallization, and coating properties of spray tanks Deterioration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

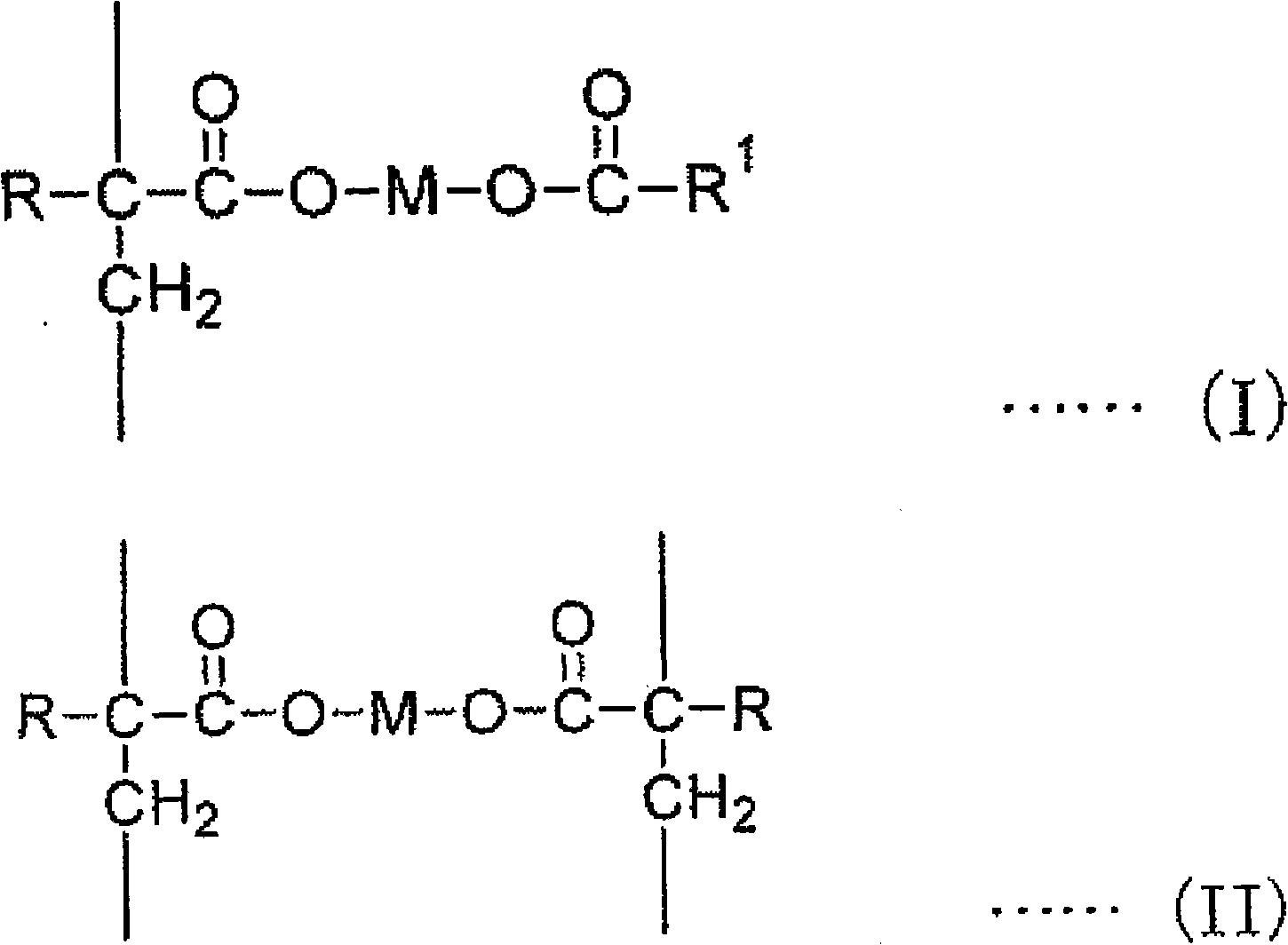

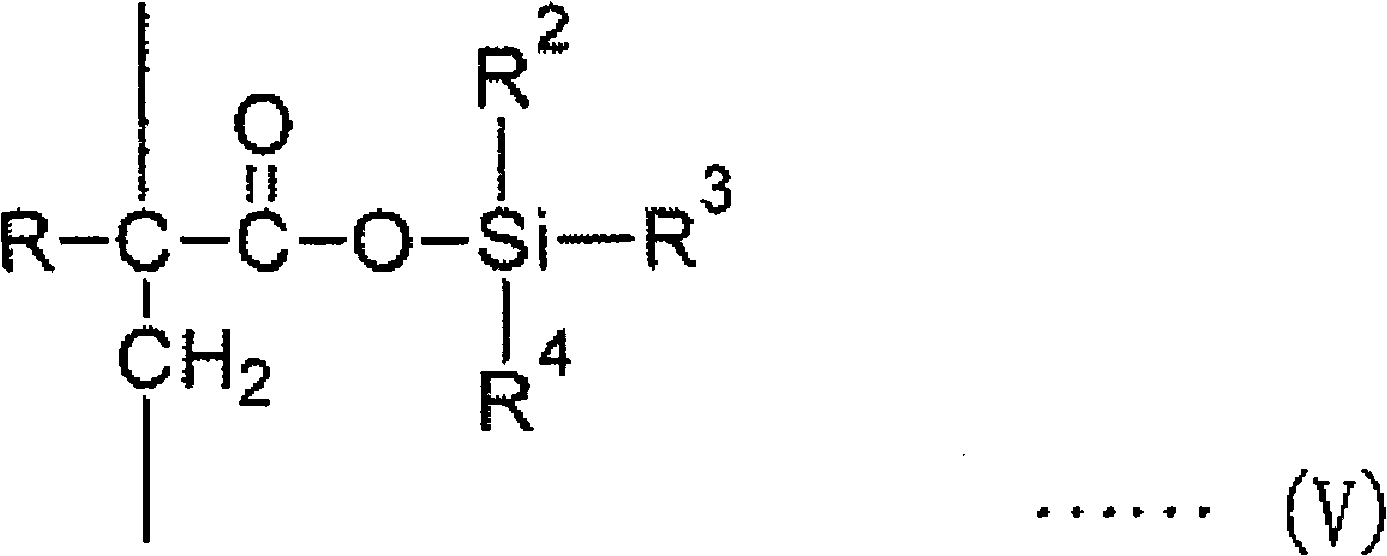

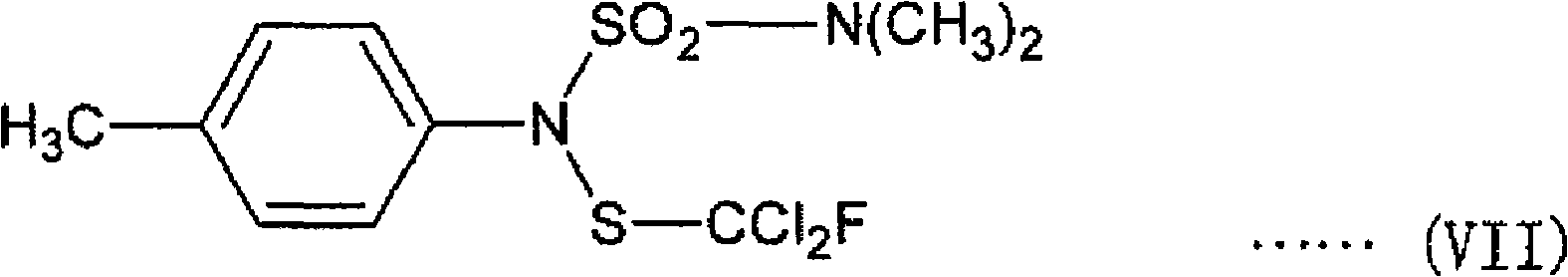

Method used

Image

Examples

Embodiment

[0078] The measurement methods of various physical properties and the like in the following examples are as follows.

[0079]

[0080] Weigh 1 g of the prepared copolymer solution in a pan, and spread it evenly with a metal wire of known mass. After drying at 125° C. for 1 hour, the mass of the residue after solvent volatilization and the wire was measured, and the solid content ratio was obtained from the calculated heating residual content (that is, solid content).

[0081]

[0082] According to 4.3 of JIS K7233, the Gardner viscosity was measured at 25 degreeC after adjusting the solid content ratio of a reaction liquid to 35 weight%.

[0083]

[0084] By using "HLC-8210GPC" manufactured by Tosoh Corporation as the measurement device, using two pieces of "TSKgel α-M" manufactured by Tosoh Corporation as the separation column, and using dimethylformamide added with 20 mM LiBr as the eluent (DMF) GPC measures the number average molecular weight (Mn) and the weight aver...

manufacture example 1

[0092] [Manufacture Example 1] Manufacture of Copolymer A

[0093] 15 parts by weight of propylene glycol monomethyl ether, 57 parts by weight of xylene and 4 parts by weight of ethyl acrylate were added to a four-necked flask equipped with a condenser, a thermometer, a dropping funnel and a stirrer, and the temperature was raised to 100° C. while stirring. Then, 37.8 parts by weight of the reaction liquid obtained by the preparation process of the preparation example 1: metal-containing monomer (a), 13 parts by weight of methyl methacrylate, 65 parts by weight of Parts of ethyl acrylate, 2.5 parts by weight of azobisisobutyronitrile (AIBN) (manufactured by Nippon Hydrazine Industry Co., Ltd.), 7 parts by weight of azobismethylbutyronitrile (AMBN) (manufactured by Nippon Hydrazine Industry Co., Ltd.) , a transparent mixture of 1 part by weight of a chain transfer agent "NOFMER MSD" (manufactured by NOF Corporation) and 10 parts by weight of xylene. After the dropwise addition...

manufacture example 2

[0097] [Production Example 2] Production of Copolymer B

[0098] 30 parts by weight of propylene glycol monomethyl ether (PGM) and 40 parts by weight of xylene were added to a four-necked flask equipped with a condenser, a thermometer, a dropping funnel, and a stirrer, and the temperature was raised to 100° C. while stirring. Then, from the dropping funnel, add 35 parts by weight of tertiary carbonic acid zinc methacrylate, 10 parts by weight of acrylate-2-methoxyethyl ester, 30 parts by weight of acrylate-3-methoxybutyl ester, 25 parts by weight of A mixture formed by parts by weight of ethyl acrylate and 6 parts by weight of tert-butyl peroxide. After the dropwise addition, 1 part by weight of tert-butyl peroctoate and 10 parts by weight of xylene as additional catalysts were dropped in 2 hours, and after stirring for 2 hours, 20 parts by weight of xylene was added to obtain a copolymer containing metal salt bonds. B's reaction solution. The solid content ratio of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com