Solar multi-directional tracking heat pipe utilization system

A solar heat pipe and solar energy technology, applied in the field of solar energy utilization, can solve the problems of inability to guarantee thermal insulation requirements, high cost, and high heat loss, and achieve the effects of reducing heat loss in collection and transmission, reducing energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

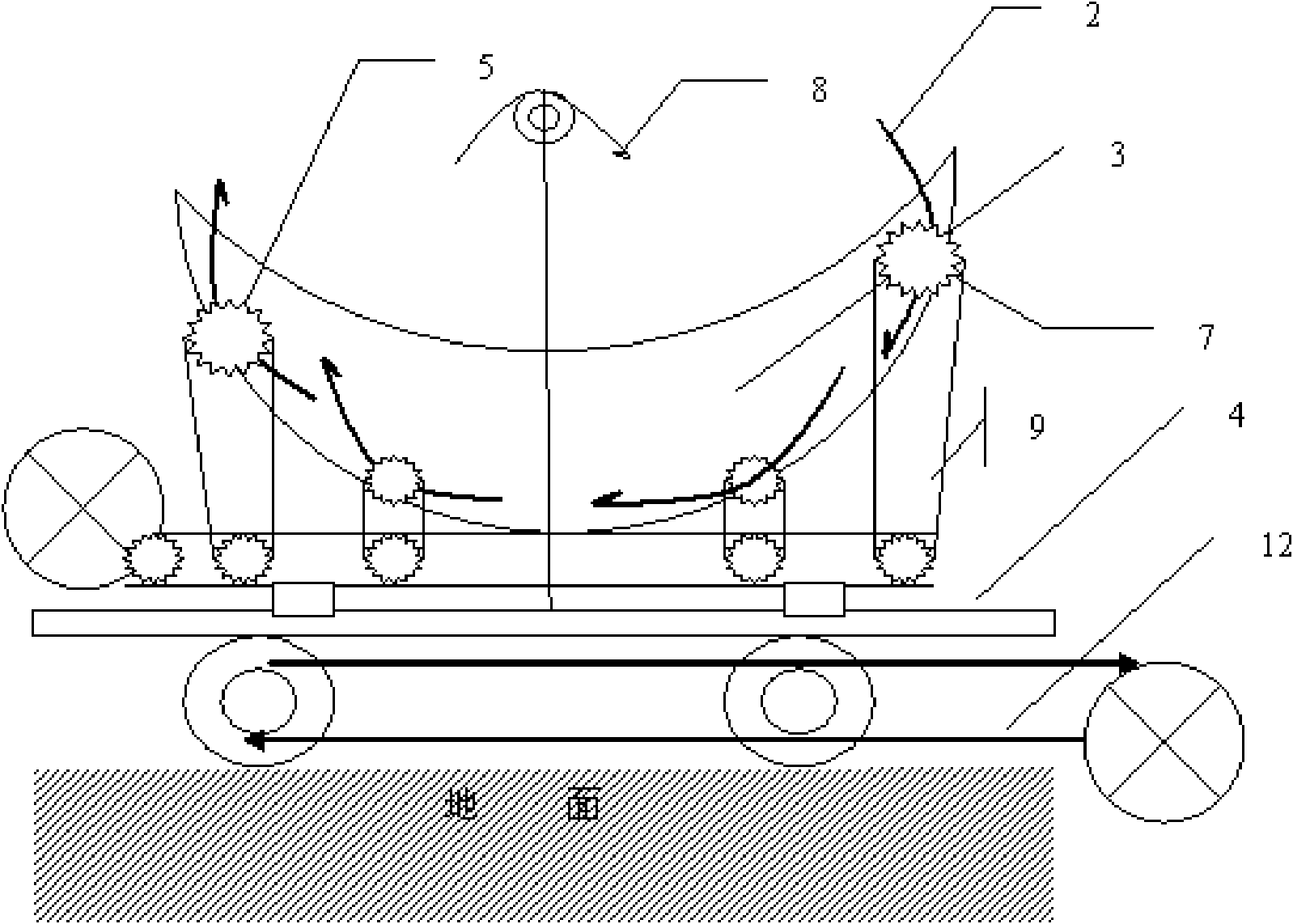

[0055] Embodiment 1: Multi-parabolic reflective heat pipe utilization system

[0056] This figure is a side view, the solar mirror (2) is four parabolic reflectors (2), the heat pipe utilization system (1) is a heat pipe arranged inside the glass tube, the outside of the heat pipe is provided with a solar coating, and the parabolic mirror is arranged on On a parabolic device, a shaft is arranged on each parabolic mirror, and the solar mirror can rotate along the rotating shaft (5). The drive of the mirror bracket (4) realizes the driving of the rotating shaft (5) and the driving of the solar mirror bracket in the parabolic device to realize the overall tracking of the solar energy; the four solar mirrors realize the tracking of the solar energy through different movements At the same time, the solar light is focused to the evaporation end (10) of the heat pipe, and various utilizations of heat energy are realized through the heat exchanger (11) arranged at the condensation end...

Embodiment 2

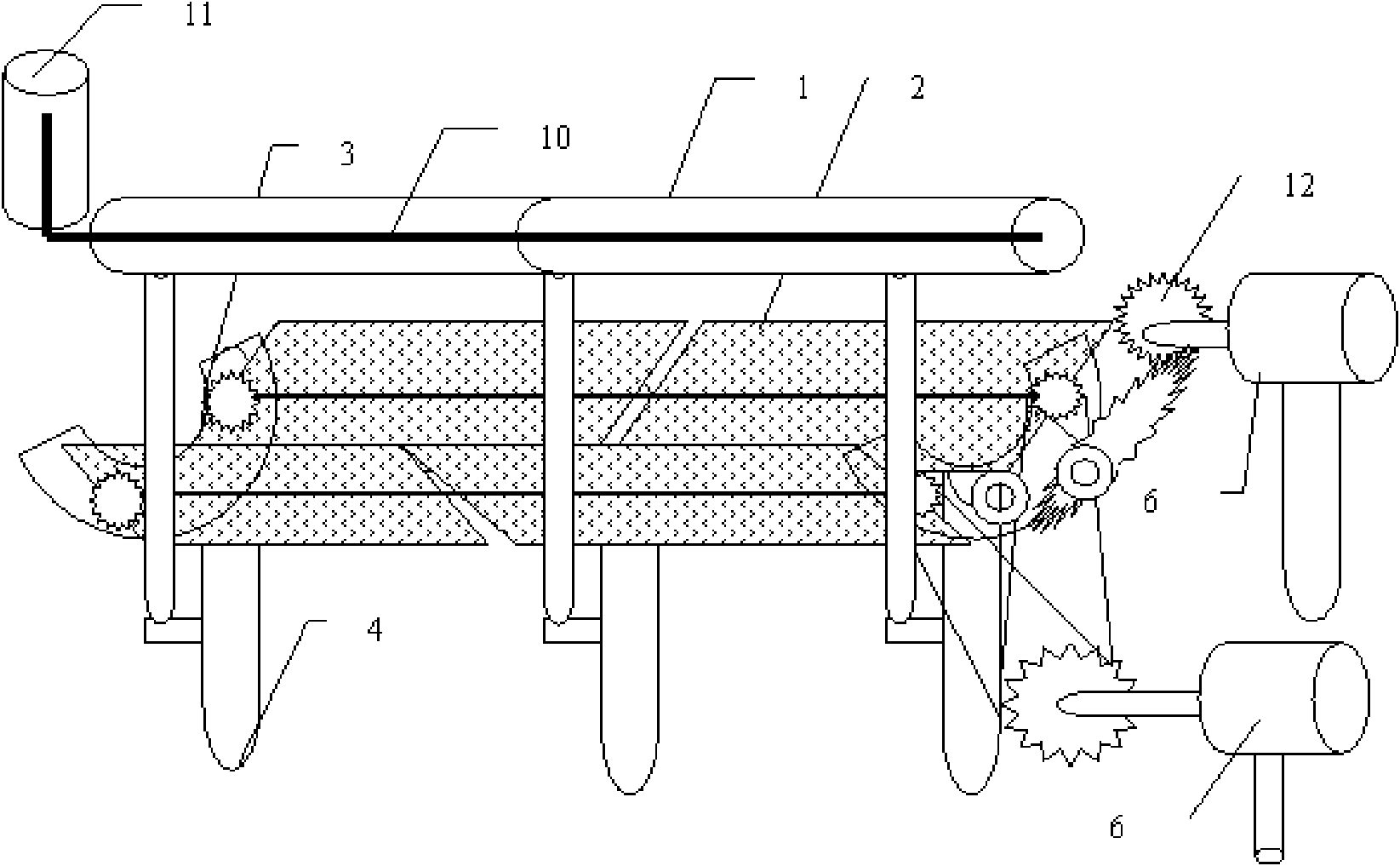

[0057] Embodiment 2: Multi-glass mirror heat pipe utilization system

[0058] Such as figure 2 As shown, this example uses two sets of glass mirrors to realize solar tracking, wherein each set of solar mirrors is two glass mirrors, and the tracking systems of the two sets of glass mirrors are connected in series; the evaporation end of the heat pipe is set on the vacuum tube, and the condensation end is set on-line focusing In the external area of the system, a heat exchanger is installed at the condensing end to realize various applications such as power generation, heating, and cooling of thermal energy. Four glass reflectors are fixed on three ring-shaped devices, the power drive device is a motor (6), the power transmission device is a gear mechanism arranged on the ring, and the motor drives the gear arranged on the ring through the gear mechanism , so that the glass mirror is turned on the ring, at the same time, the driving device (12) to the solar mirror support (4...

Embodiment 3

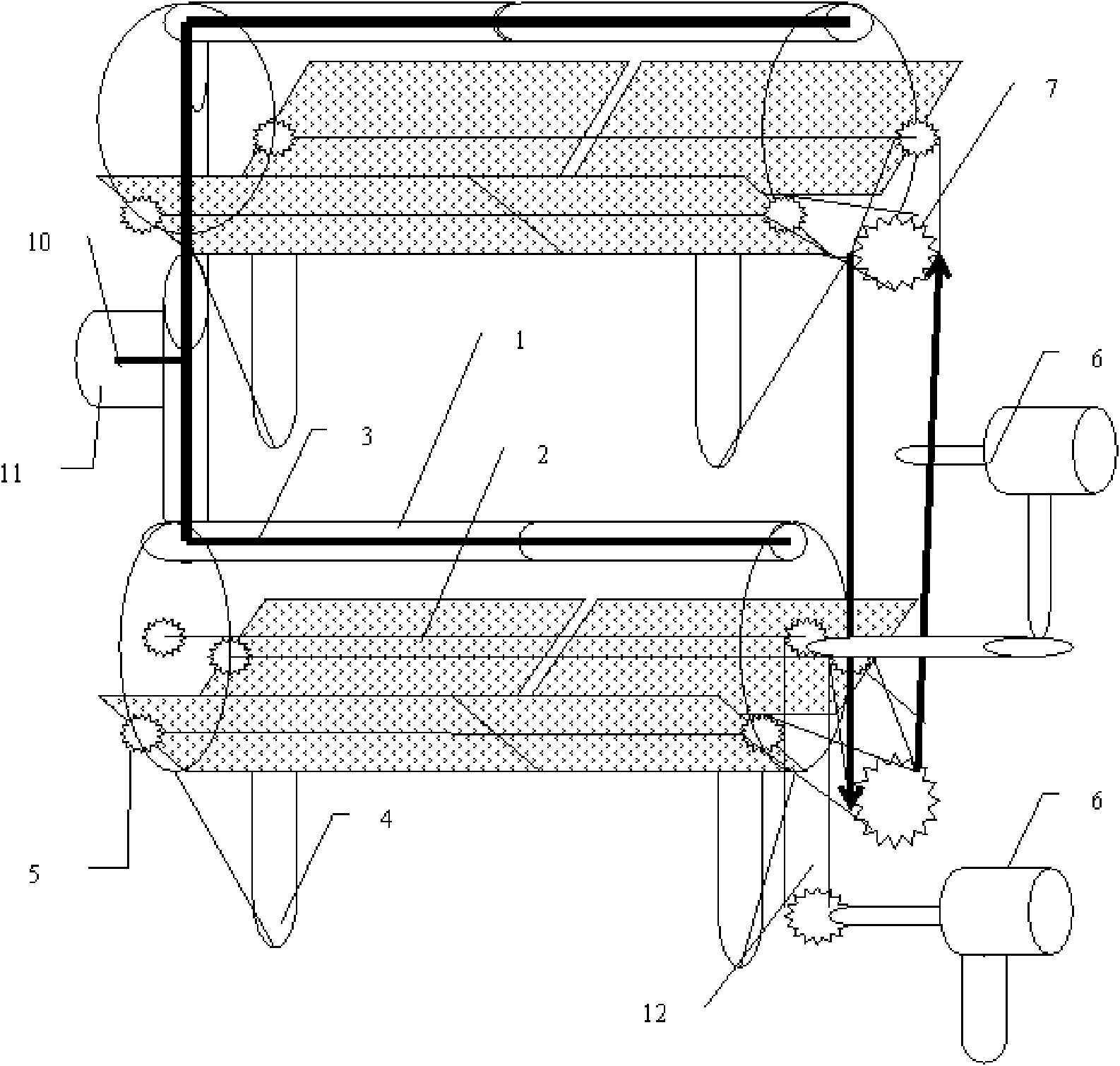

[0059] Embodiment 3: Multi-Fresnel Mirror Array Tracking Heat Pipe Utilization System

[0060] Such as image 3 As shown, this case is a multi-mirror array tracking system, using four Fresnel mirrors, the power drive device is a motor, the motor drives two gears set on the focal line shaft through the power transmission equipment of the chain, and also sets There is a system that drives the solar mirror bracket (3) to provide the driving force, so that the solar mirror system can move along the semi-circular bracket, so that multi-directional tracking can be realized; the solar tracking of the 2*2 array can be realized, and the heat pipe system The evaporation end is set in the focal line area of the online focusing system, and the condensation end is set outside the focal line area, so as to realize the utilization of various thermal energy of solar energy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com