Central heating system and method for coupling circulating water heat pump of power plant with cogeneration

A technology for co-generation of heat and power and circulating water, applied in the energy field, can solve the problems of affecting the quality of life, low energy efficiency of heat pumps, poor heating effect, etc., and achieve the effect of regional central heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

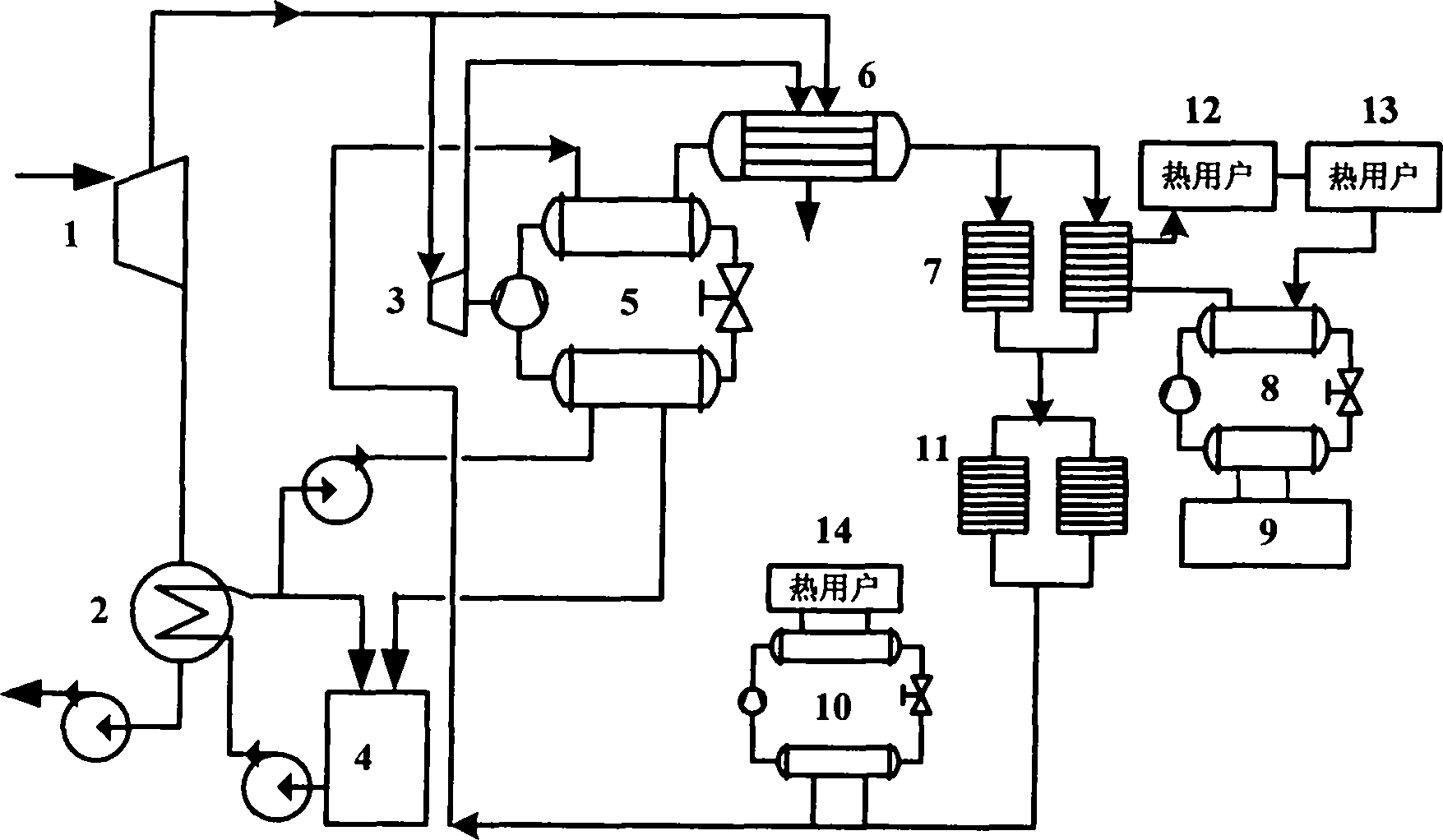

[0018] The steam enters the steam turbine 1 of the power plant to do work, and the exhaust steam from the steam turbine 1 of the power plant enters the condenser 2 to be condensed and sent to the boiler feed water. The circulating cooling water of the condenser is extracted from the circulating water cooling facility 4 of the power plant, and the circulating water enters the condenser 2 to participate in heat exchange, and the temperature rises. Part of the high-temperature circulating water goes to the circulating water cooling facility 4 of the power plant for cooling, and the other part is used as the first type The low-temperature heat source of the heat pump system, after being absorbed by the heat pump system 5 of the first type, its temperature is lowered, and the water after lowering the temperature also flows into the circulating water cooling facility 4 of the power plant. Part of the steam that has done work in the steam turbine 1 is extracted, and a part of it is se...

Embodiment 2

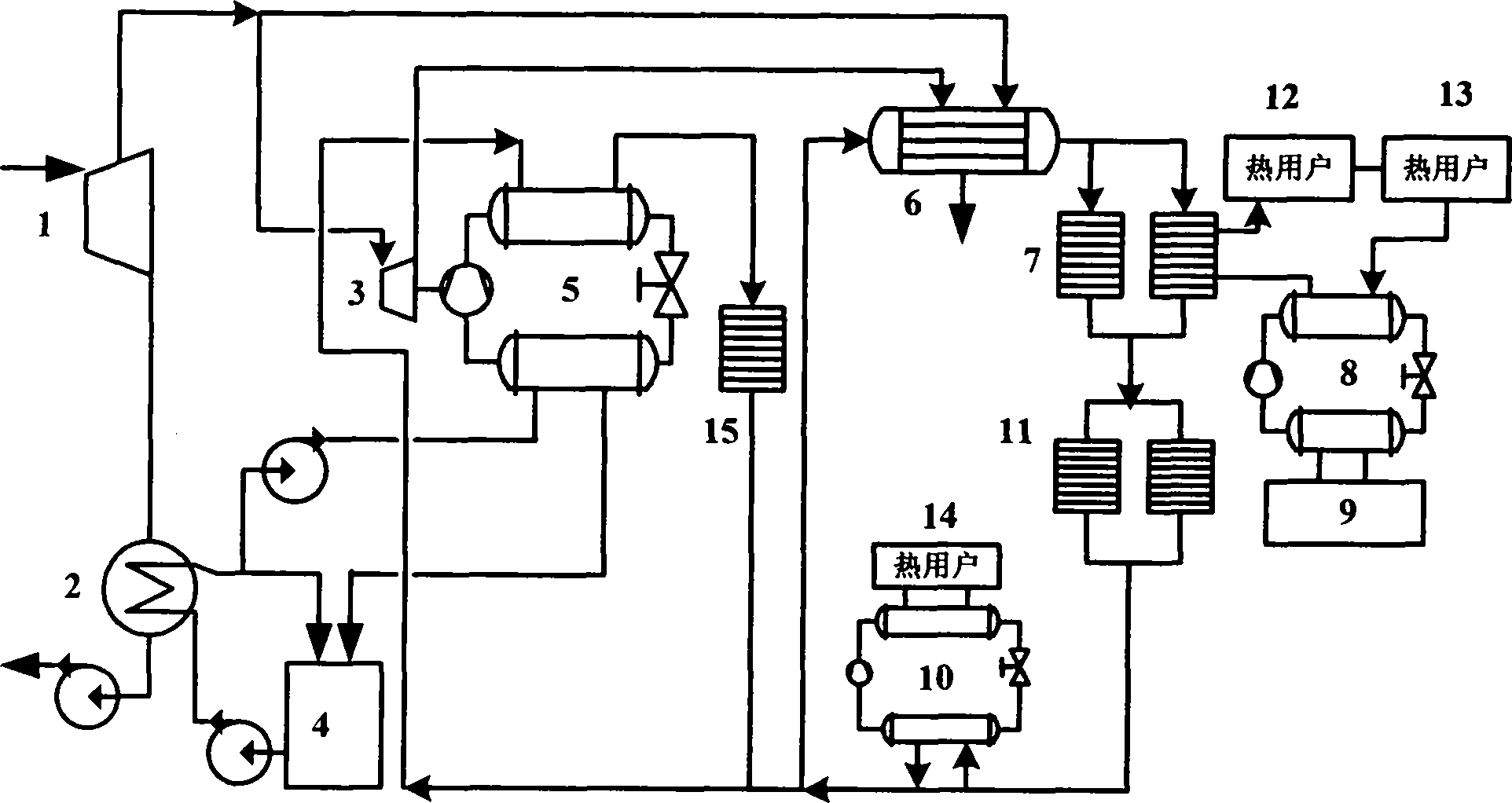

[0021] Embodiment 2 is similar to Embodiment 1, the difference is that the first type of heat pump in Embodiment 1 heats the heat network water and then is heated by the heat network heater, and then sent to the secondary heat network heater 7 to provide heating for users, while in Embodiment 1 The first type of heat pump in 2 realizes close-distance heating for the area near the power plant.

[0022] In Example 2, after the heating network water of the primary heating network returns to the power plant, part of it enters the first type heat pump system 5 for heating, and part of it enters the primary heating network heater 6 for heating. The heating network water heated by the first type heat pump system 5 is transported to the area near the power plant to realize short-distance heating, while the heating network water heated by the primary heating network heater 6 realizes long-distance heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com