Light-colored low-phosphorous dimer acid production process

A low-phosphorus dimer acid and production process technology, applied in the direction of carboxylate preparation, separation/purification of carboxylic acid compounds, preparation of organic compounds, etc., can solve the problem of not meeting the requirements of high-quality and high-purity dimer acid Produce polymers, self-produced and self-used, etc., to achieve the effect of improving color and transparency, improving yield and quality, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

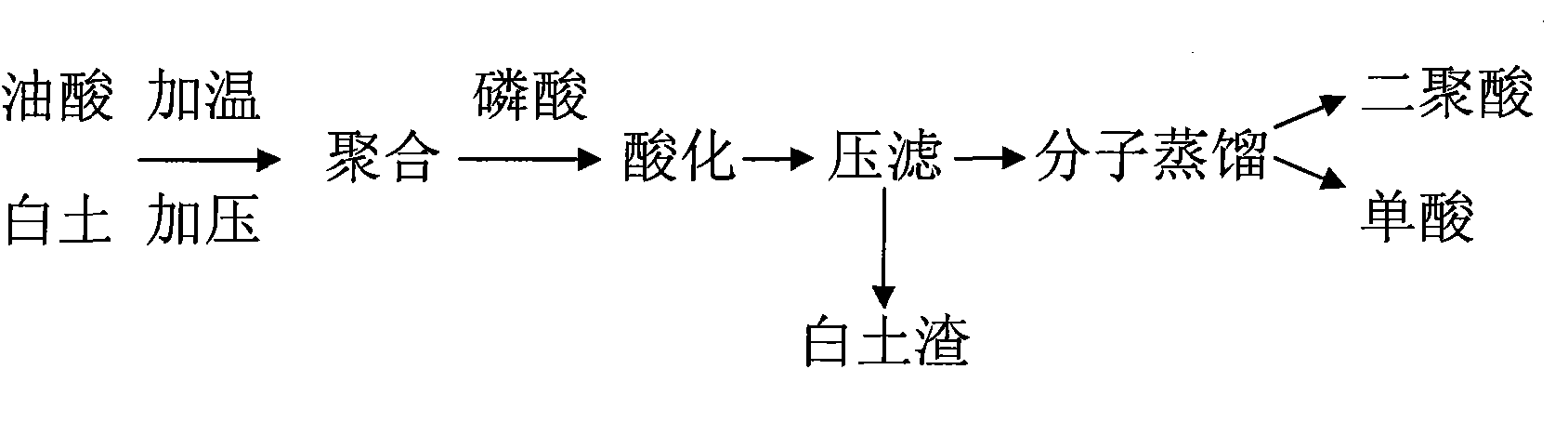

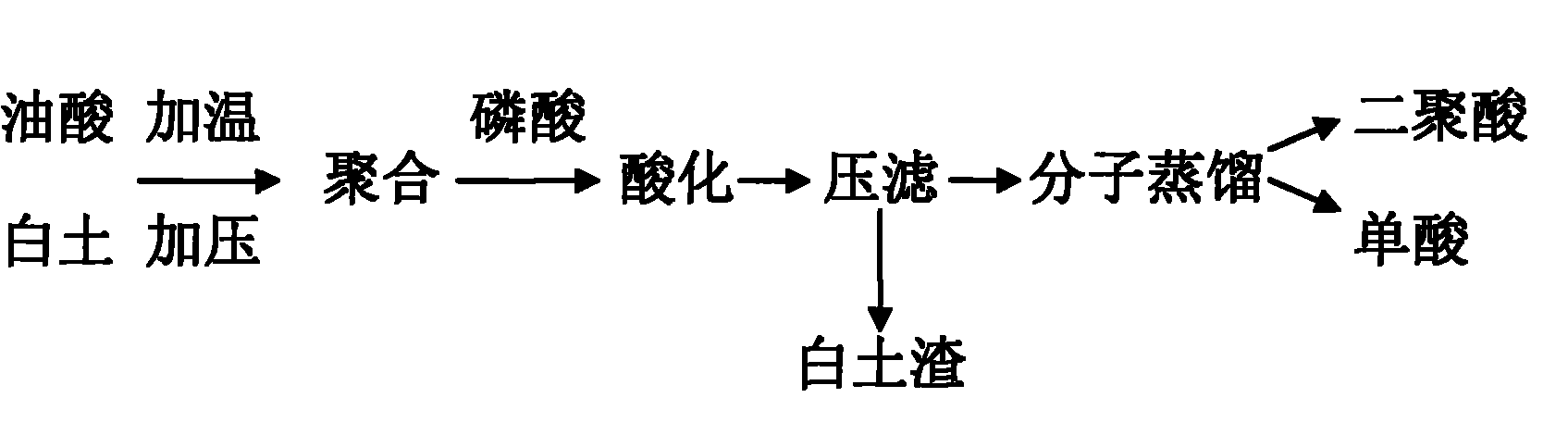

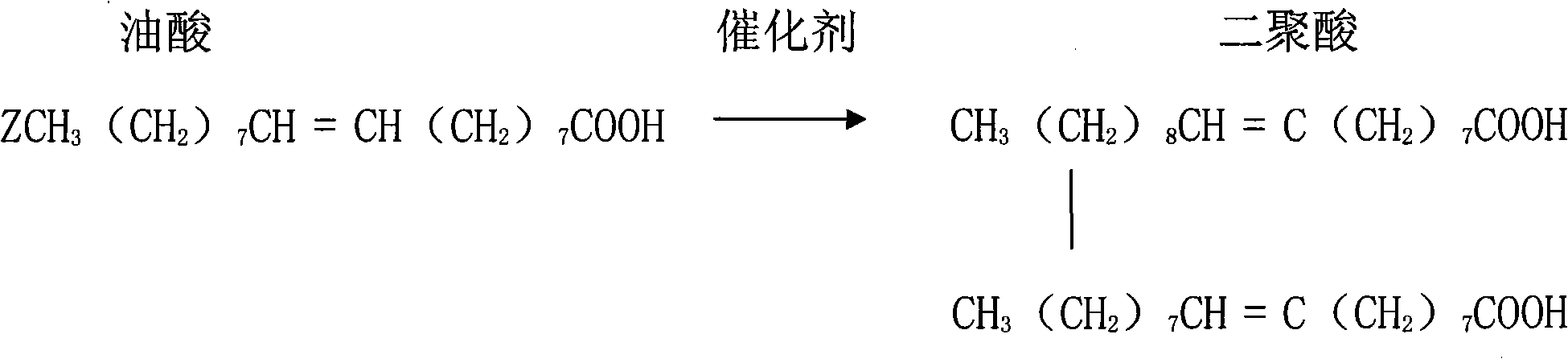

[0010] Examples, as shown in Figure 1, include

[0011] 1) Polymerization, add high-purity distilled water during polymerization, add acid clay catalyst, heat, pressurize and polymerize;

[0012] 2) Acidification, filtration, filtration after acidification, adding high-purity water, heating and stirring, standing still, draining clear water, and then entering a high-speed centrifuge for separation and filtration;

[0013] 3) Molecular distillation. Molecular distillation is continuous distillation. Under multi-stage Roots high vacuum, the crude dimer acid is continuously fed into the thin-film evaporator to remove the low boiling point and moisture in the material, and then enters the short-range evaporator for separation. Obtain dimer acid and monomeric fatty acid;

[0014] 4) Washing, the dimer acid produced above is washed with ultrapure water to obtain a light-colored low-phosphorus dimer acid product.

[0015] Add 1% high-purity distilled water during the polymerization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com