Packing layer for a structured package

A technology of structured packing and packing layers, applied in chemical/physical/physicochemical processes, chemical instruments and methods, through absorption, etc., can solve problems such as high material consumption and pressure loss, achieve high stability, and achieve the effect of contact points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

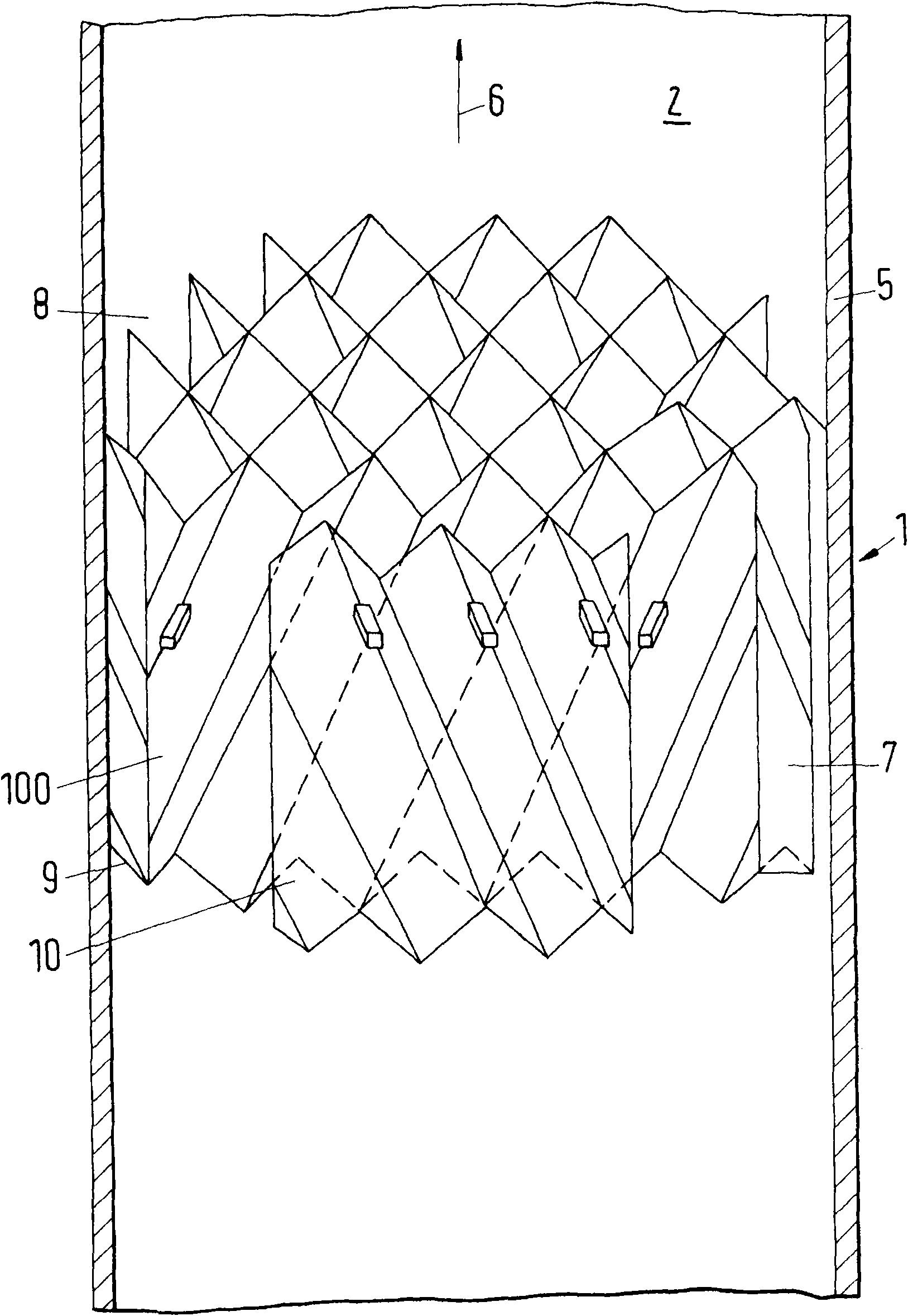

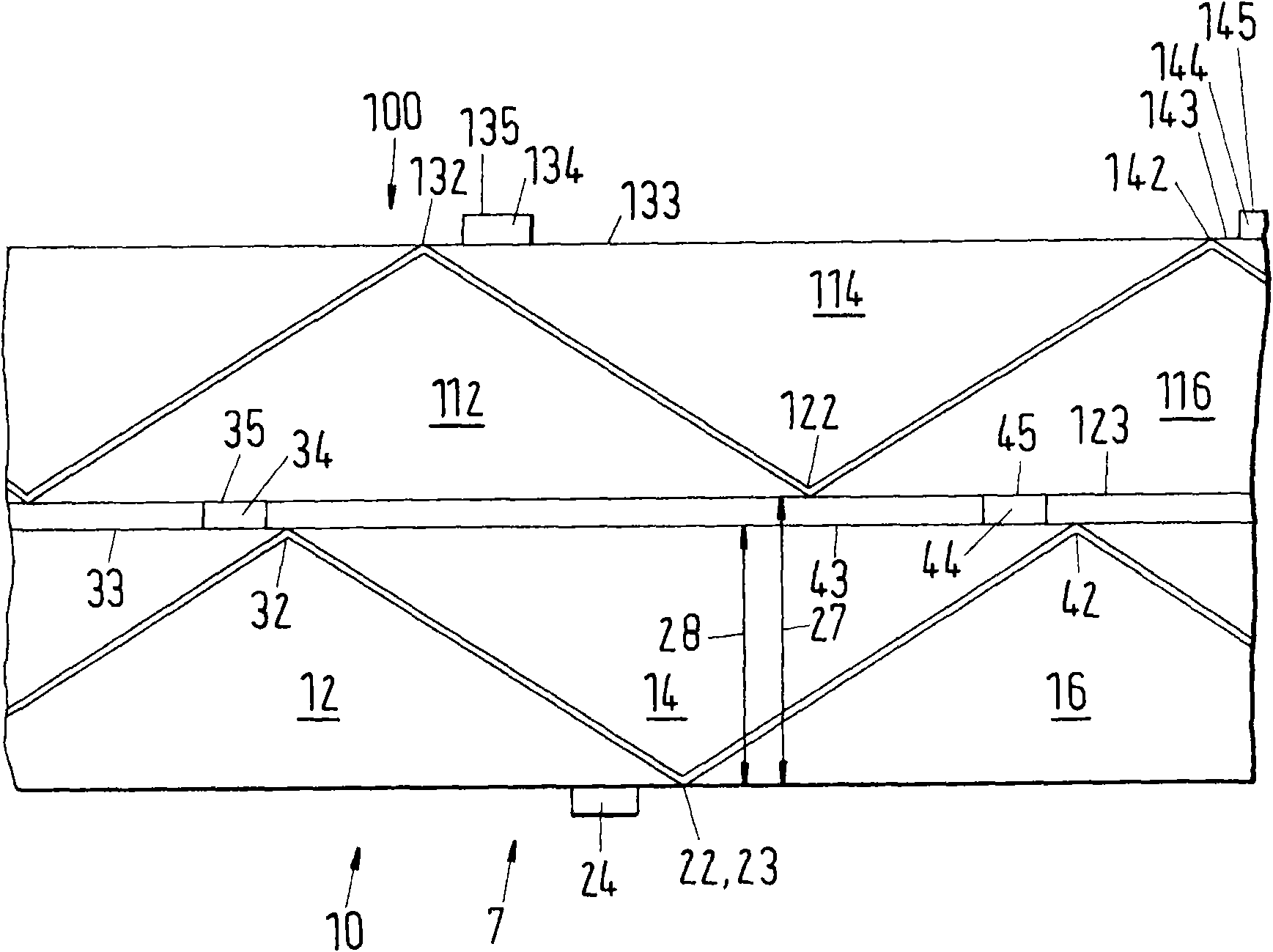

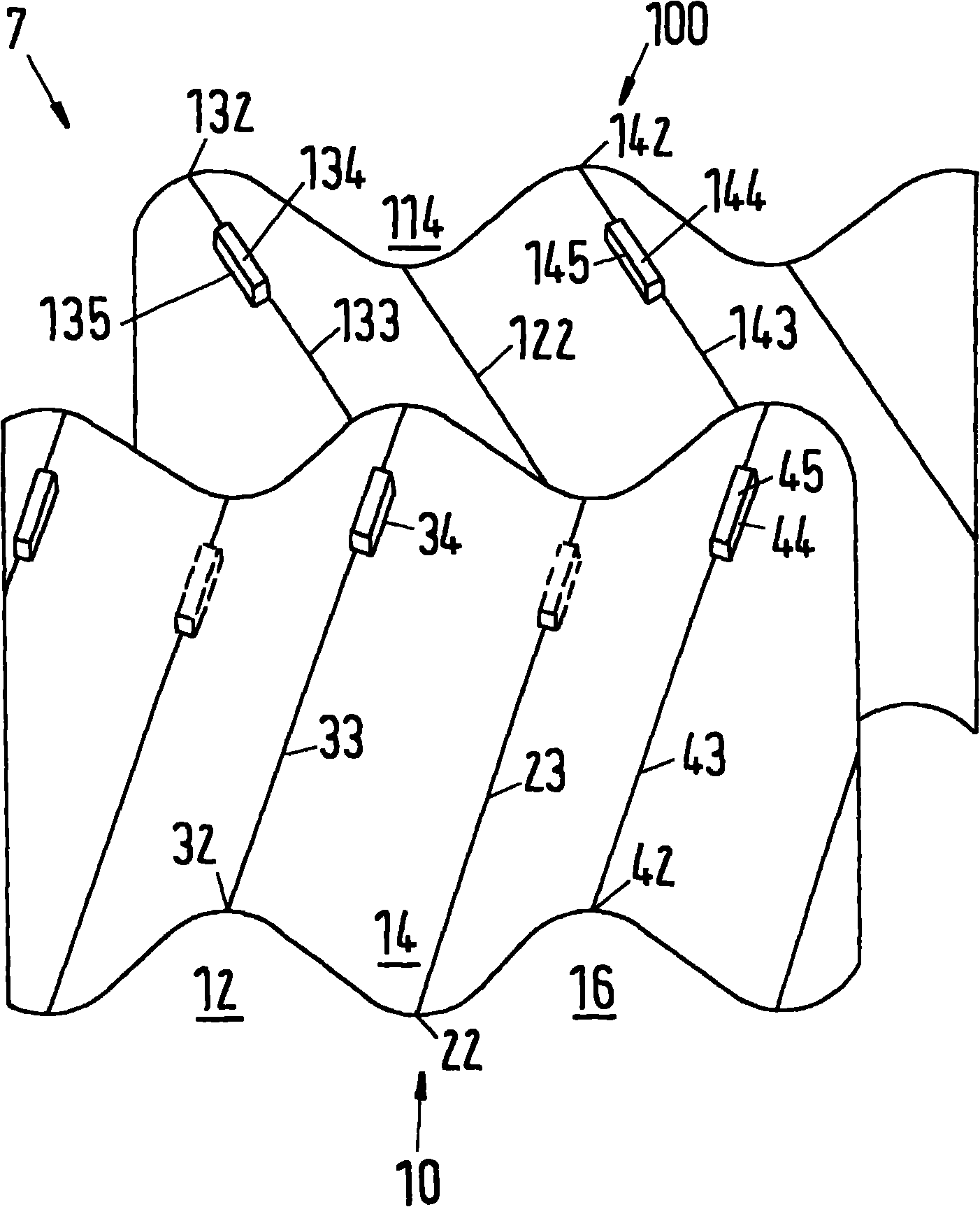

[0056] figure 1 A device 1 according to the invention is shown comprising certain packing layers of a structured packing 7 forming a packing body. A device for transferring mass between two fluid phases is to be understood as a structured packing 7 . Structured packing 7 is used in mass transfer device 2 . The mass transfer device can in particular be made as a column 5 .

[0057] The structured packing 7 is made of a plurality of packing layers in a regularly repeating geometric relationship with respect to each other. As an example for such a geometry, the distance between adjacent packing layers can be chosen. Depending on the geometry, the distances of adjacent packing layers from each other can periodically assume the same value, so that a structure is produced from the sum of the packing layers, which is characterized by the same or at least periodically the same distances. This periodicity exists in general structured packings, thereby giving the packings a regular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com