Cooling device of flame detector

A technology of flame detectors and cooling devices, which is applied to the cooling of instruments, parts of instruments, instruments, etc., and can solve the problems of not being able to see light, inconvenient operation, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

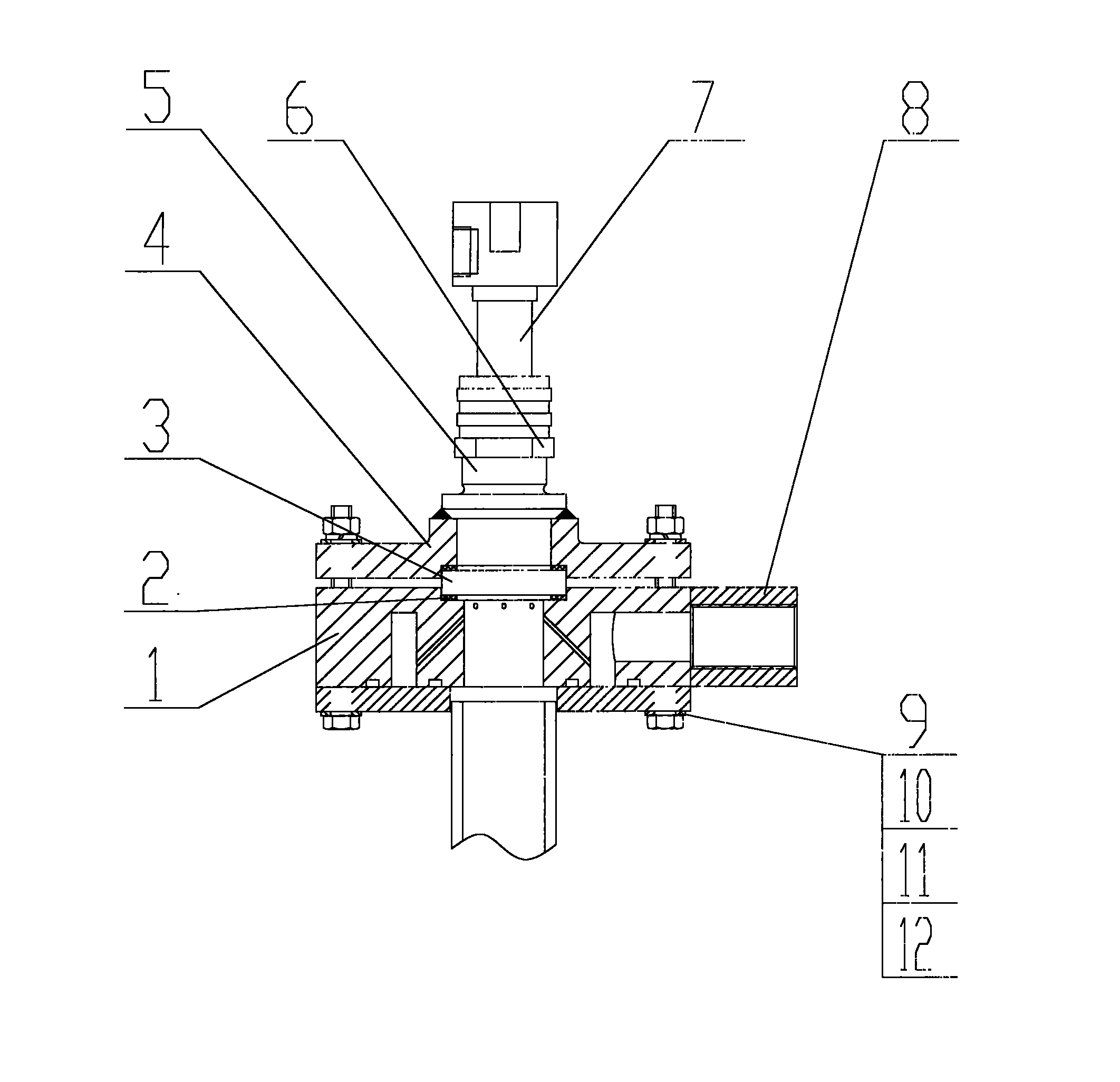

[0014] A cooling device for a flame detector of the prior art shown in accompanying drawing 1 includes a cooling plate 1, a pressing plate 4, a glass plate 3, and a transition joint 5; the pressing plate 4 presses the glass plate 3 on the cooling plate, and passes through 4 groups Bolts 12, nuts 11, flat washers 9, and spring washers 10 are fixed on the cooling plate 1; a sealing ring 2 is arranged between the glass plate 3 and the pressing plate; one end of the transition joint is welded on the pressing plate 4, and the other end is connected to a flame detector 7; There is a through hole on the cooling plate, and the flame detector 7 can be seen in the through hole through the glass plate 3 . The cooling plate 1 is provided with a joint 8, and the through hole communicates with the joint through an air channel, and the air channel is inclined upward, so that the cooling nitrogen is blown upward, causing the high-temperature gas to directly act on the filter glass plate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com