Staircase guardrail bottom reinforced seat

A technology for reinforcing seats and guardrails, which is applied in the direction of ladder-like structures, building structures, buildings, etc., can solve problems such as left and right shaking, instability, hidden dangers, etc., and achieve the effects of maintaining stability, installation stability, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

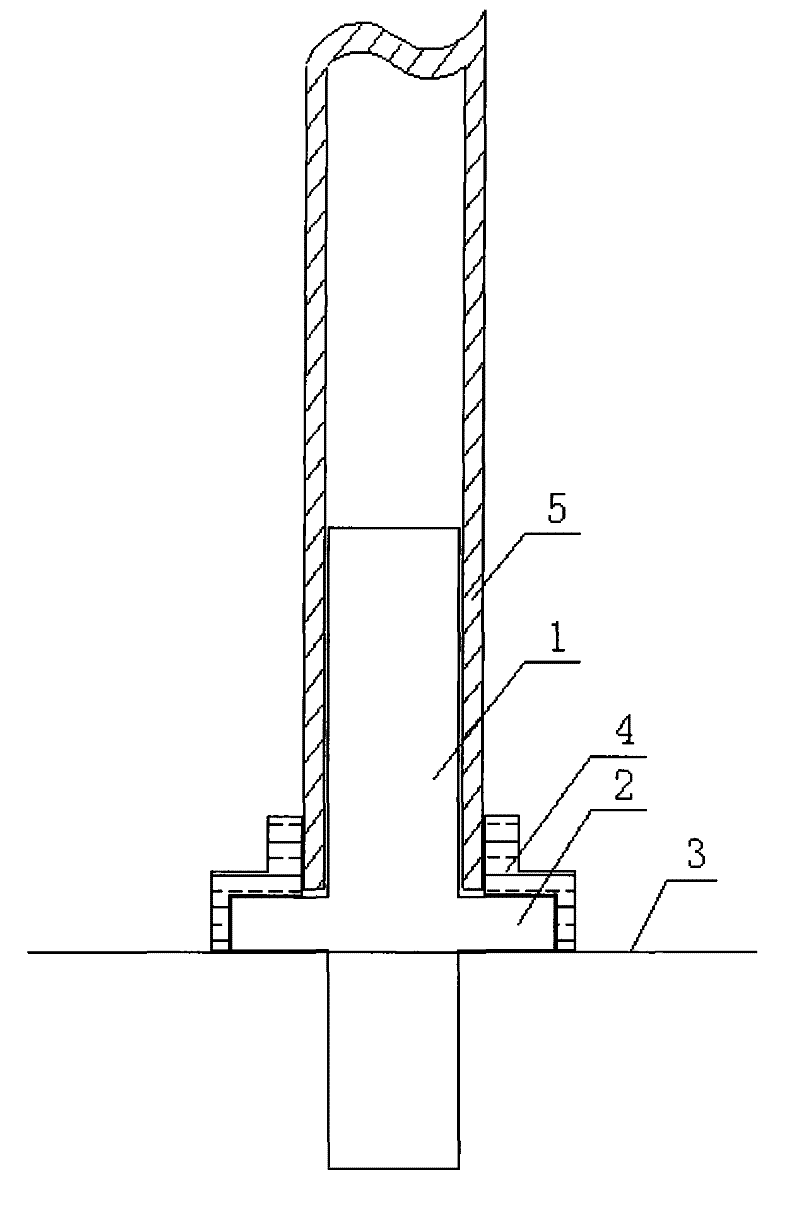

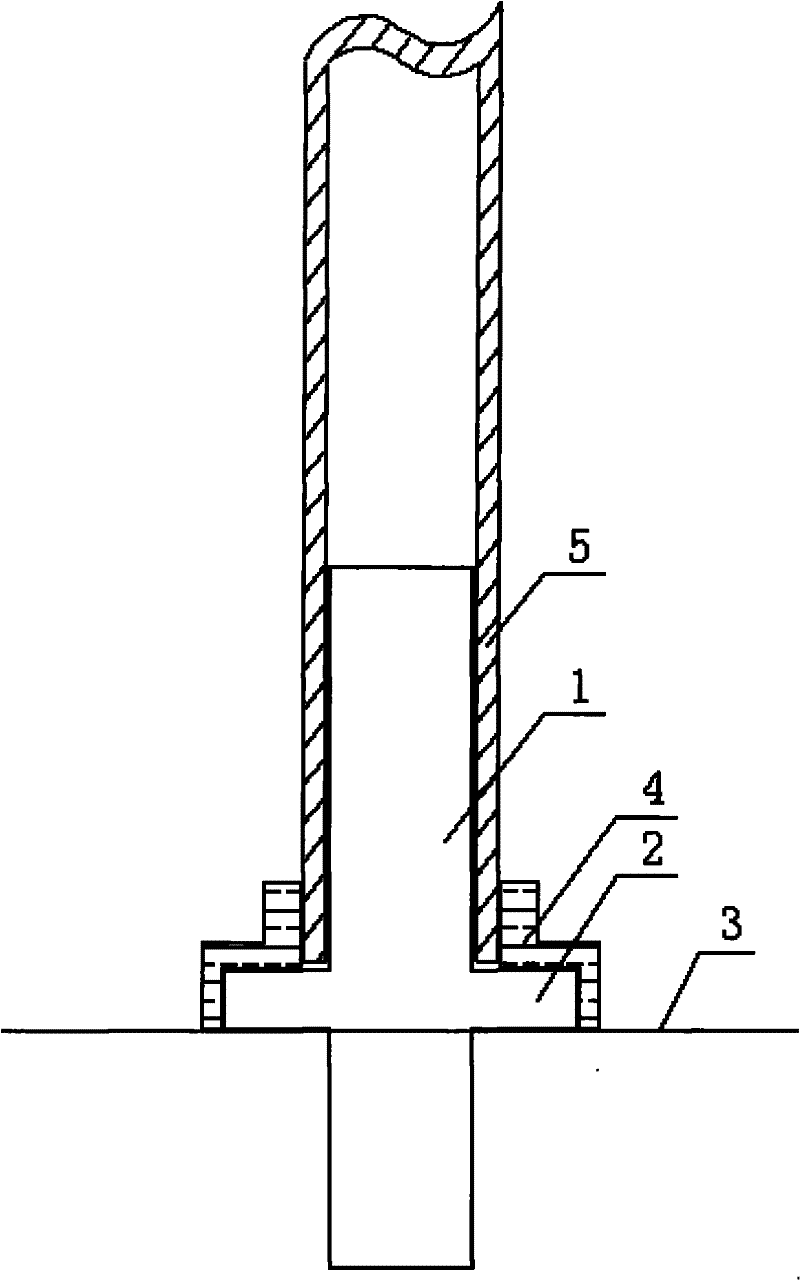

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a cylindrical fixed block 1 with one end extending into the ground, the interior of the fixed block 1 is filled with colloid, and the side of the fixed block 1 close to the ground 3 is provided with a boss 2; the boss 2 is provided with a base protection pad 4; the boss 2 is equipped with screws for fixing.

[0016] By drilling holes on the ground 3, insert the fixed block 1 into the ground until the boss 2 is close to the ground 3, pour colloid into the interior of the fixed block 1 to connect it with the ground, and screw the boss 2 on the ground to fix.

[0017] The stair guardrail 5 is set on the part of the fixed block 1 exposed to the ground 3, and the base pad 4 for fixing the stair guardrail 5 is set on the boss 2 to prevent the stair guardrail from shaking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com