Abrasion-resistant and friction-reducing emulsion and preparation method for spraying same on surface of soft metal

A soft metal and emulsion technology, which is applied to the surface coating liquid device, special surface, pre-treated surface, etc., can solve the problems of easy intrusion into soft metal substrates, sharp corner burrs of matching parts, low hardness, etc., and achieve coating Reasonable thickness, improved anti-friction ability, improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Wear-resistant anti-friction emulsion 1 is composed of the following components by weight percentage:

[0045] PTFE emulsion 50

[0047] Phosphoric acid 5.4

[0048] Sodium lauryl sulfate 0.4

[0049] distilled water 40

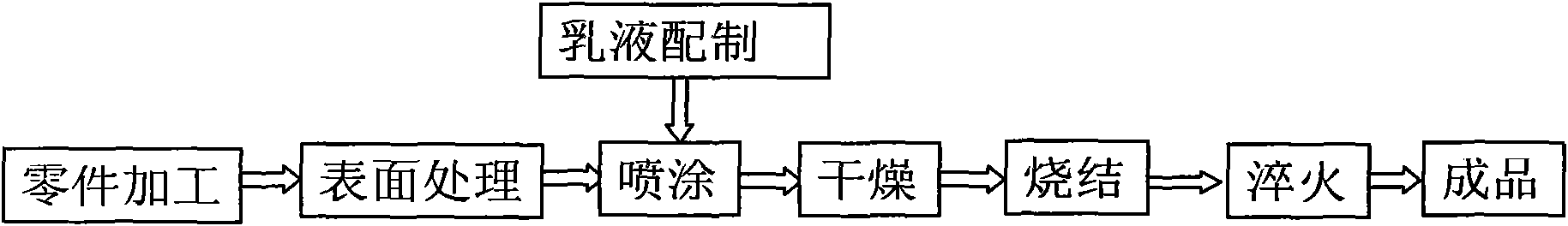

[0050] Such as figure 1 As shown, the above-mentioned wear-resistant and anti-friction emulsion is sprayed on the soft metal surface according to the following preparation steps:

[0051] 1. Parts processing: process soft metals according to the requirements of the drawings, and the thickness of the surface to be sprayed should be reduced to the thickness of the coating.

[0052] 2. To prepare wear-resistant and anti-friction emulsion, add the sodium lauryl sulfate in the ratio of this embodiment into the polytetrafluoroethylene emulsion, and then drop the mixed solution of phosphoric acid, chromium oxide and distilled water into lauryl sulfuric acid Sodium and polytetrafluoroethylene emulsion mixture, while stirring c...

Embodiment 2

[0062] Wear-resistant anti-friction emulsion 2, consisting of the following components by weight percentage:

[0063] PTFE emulsion 69

[0064] Chromium oxide 5.9

[0065] Phosphoric acid 4.9

[0066] Sodium lauryl sulfate 0.2

[0067] distilled water 20

[0068] The preparation method of above-mentioned wear-resisting friction-reducing emulsion 2 spraying on soft metal surface is the same as embodiment 1

Embodiment 3

[0070] Wear-resistant friction-reducing emulsion 3, consisting of the following components by weight percentage:

[0071] PTFE emulsion 60

[0072] Chromium oxide 2

[0073] Phosphoric acid 2.5

[0074] Sodium lauryl sulfate 0.3

[0075] Distilled water 35.2

[0076] The preparation method of spraying the above-mentioned wear-resistant and friction-reducing emulsion 3 on the soft metal surface is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com