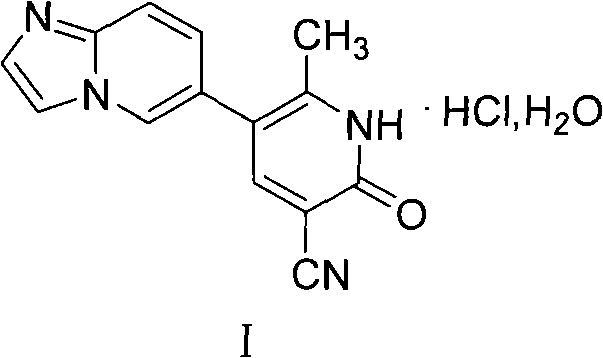

Olprinone hydrochloric acid crystal form and preparation method thereof

A technology of Opryl and hydrochloric acid, which is applied in the field of crystal form and preparation of Oprylon hydrochloride, and achieves the effects of high purity, increased myocardial contractility and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 15.0g of crude Oprinone hydrochloride and 100mL of purified water to a 100mL flask, and heat up to 100°C; after it dissolves, keep stirring for 15 minutes; heat suction filtration, transfer the filtrate into another one-necked bottle, and put the one-necked bottle into a container In 5L of hot water, the water temperature is 85°C, keep stirring to allow the 85°C hot water to cool down to room temperature (25°C) naturally, after the crystallization is complete, filter with suction, and dry to obtain 13.7g of the crystalline form of optrinone hydrochloride, with a yield of 91.3% .

[0046] The long-term stability of the obtained crystal form was investigated, and the test results are shown in Table 3. The results showed that the obtained oprenone hydrochloride crystal form was stable.

Embodiment 2

[0048] Add 10.0g of crude Oprinone hydrochloride and 70mL of purified water to a 100mL flask, and heat up to 100°C; add 0.50g of activated carbon after it dissolves, and keep stirring for 15 minutes; heat suction filtration, transfer the filtrate to another one-necked bottle, and Put the one-mouth bottle into 5L of hot water, the water temperature is 90°C, keep stirring to let the 90°C hot water cool down to room temperature naturally, the crystallization is complete, filter with suction, wash the filter cake once with 20mL of acetone, and filter the cake with suction Air-dried to constant weight to obtain 9.2 g of the crystalline form of oprinon hydrochloride with a yield of 92%.

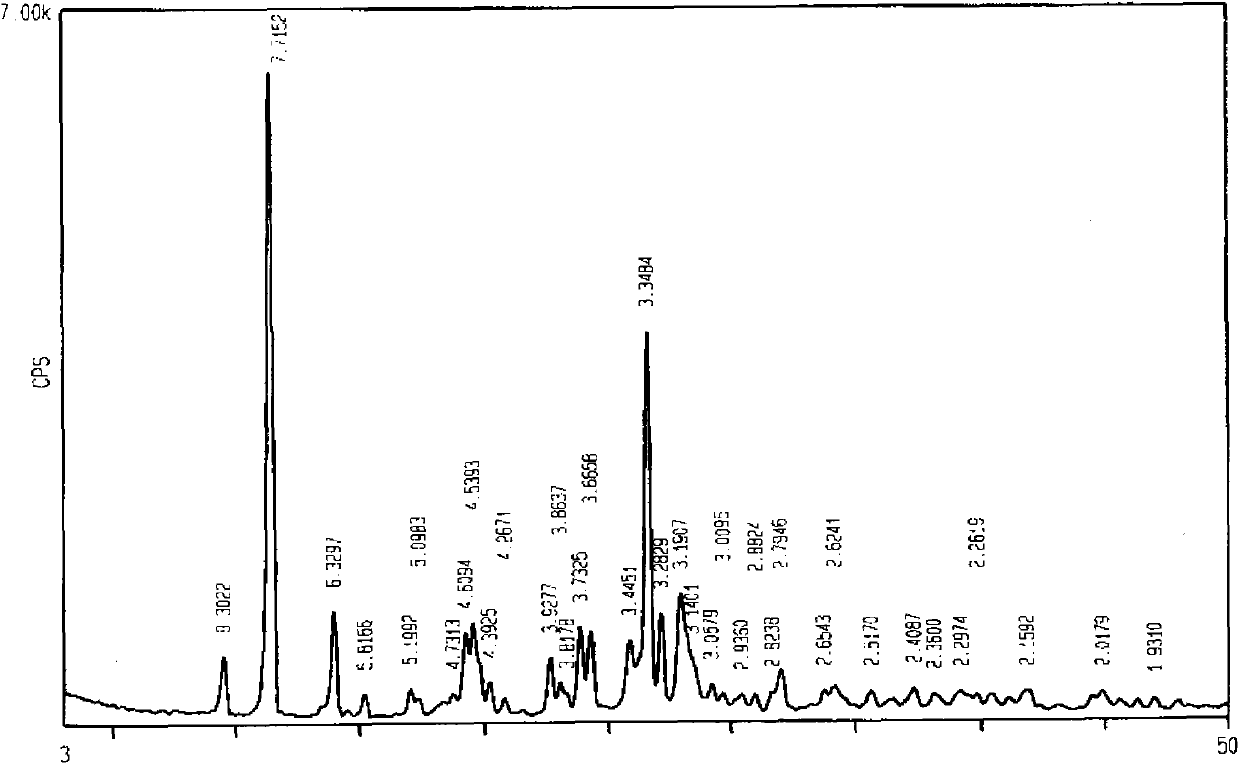

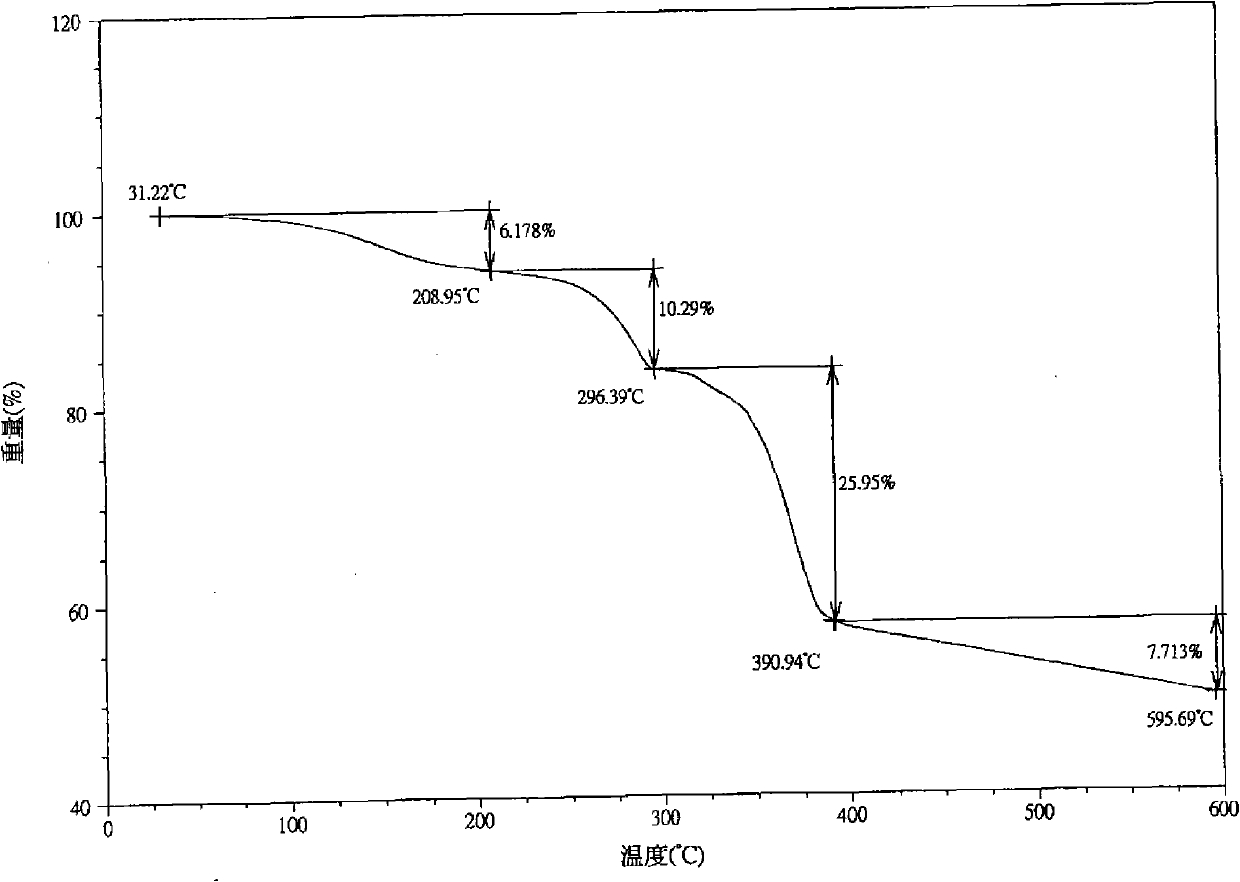

[0049] The X-ray powder diffraction pattern of gained crystal form is as figure 1 Shown, differential scanning calorimetry analysis (DSC-TGA) see figure 2 Shown and Table 2. The stability of the obtained crystal form under the conditions of high temperature (60° C.), high humidity (92.5%), and l...

Embodiment 3

[0051]Add 200.0 g of crude Oprinone hydrochloride and 1400 mL of purified water into a 2L flask, and heat up to 100°C; add 10.0 g of activated carbon after it dissolves, and keep stirring for 15 minutes. Heat suction filtration, transfer the filtrate to another single-necked bottle, and keep stirring in a water bath at 85°C for 25 minutes; then set the water bath to 70°C, and continue to keep stirring at this temperature for 25 minutes; then set the temperature of the water bath to 55 °C, keep stirring at this temperature for 25 minutes; then keep warm at 40°C for 25 minutes; finally set the temperature of the water bath to 25°C, keep stirring at this temperature for 1.5 hours. Suction filtration, the filter cake was beaten with 800 mL of acetone for 15 minutes, suction filtration, and the filter cake was aired at room temperature to constant weight to obtain 186.0 g of Opalinon hydrochloride crystal form, with a yield of 93%.

[0052] The long-term stability of the obtained c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com